Materials used for laser cutting in the aerospace industry include titanium alloys, nickel alloys, chromium alloys, aluminum alloys, beryllium oxide, stainless steel, molybdenum titanate, plastics and composites, etc.

Titanium alloys are mainly used in aircraft, and have been converted from secondary load-bearing structural parts to main structural parts. Aluminum alloys are the main structural materials for launch vehicles and various spacecraft. By comparing the traditional welding and laser hybrid welding of aluminum alloy and titanium alloy, it highlights the advantages of laser processing, such as energy concentration, easy operation, high flexibility, energy saving and environmental protection, high quality and high efficiency.

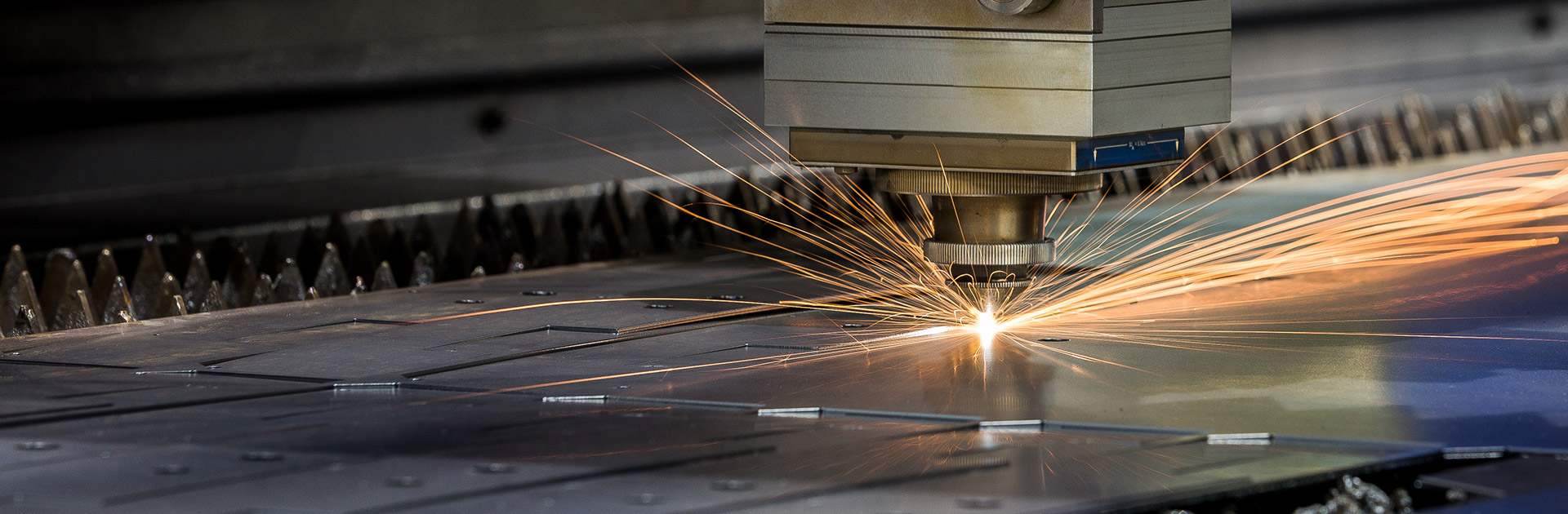

Materials used for laser cutting in the aerospace industry include titanium alloys, nickel alloys, chromium alloys, aluminum alloys, beryllium oxide, stainless steel, molybdenum titanate, plastics and composites. Laser cutting can be used to process aircraft skins, honeycomb structures, frames, wings, tail panels, helicopter main rotors, engine casings and flame tubes. Laser cutting generally uses continuous output lasers YAG and CO2 lasers, and high repetition frequency CO2 pulsed lasers are also used.