Automotive Manufacturing Solutions

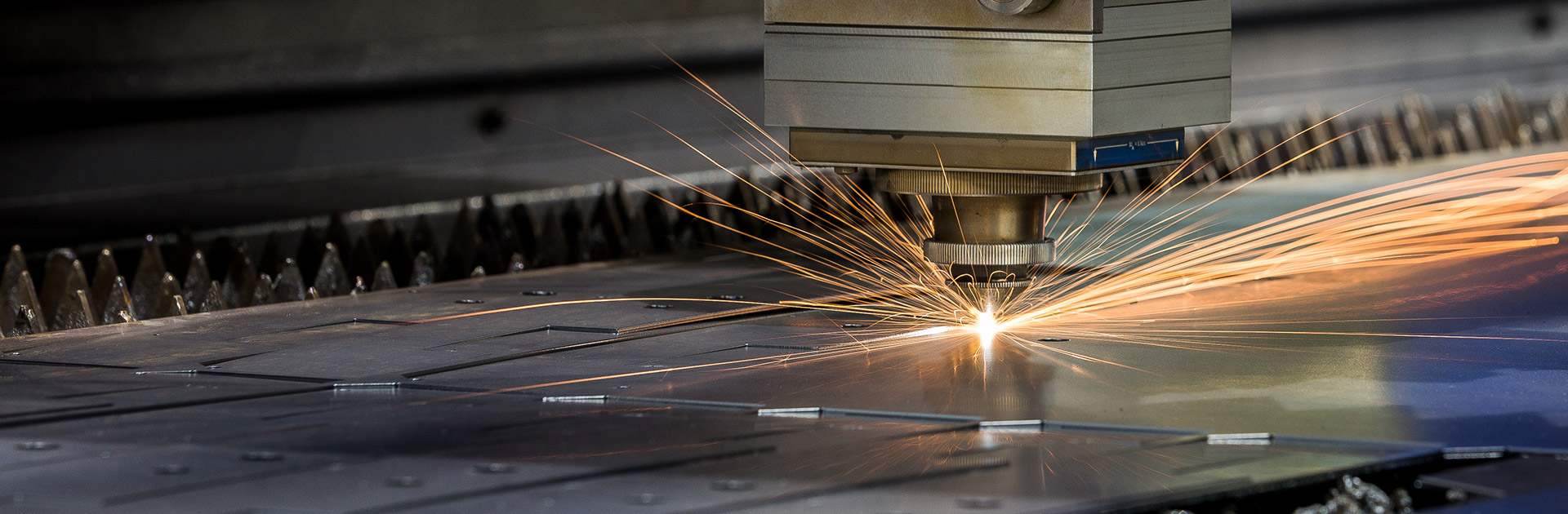

Laser welding technology can improve the strength of the body and ensure the high precision of the assembly of auto parts.

Laser welding technology also plays an important role in reducing vehicle body weight, improving user comfort, and ensuring user safety.

Laser welding has become a standard process in the automotive industry. Many international automotive industry production lines use laser welding robots. Volkswagen of Germany uses laser welding equipment for the roof welding of Audi A6, lf A4 and Passat brand models.

Over the years, Herolaser has participated in the research and development of intelligent laser welding production lines for car body-in-white. Herolaser's intelligent welding products can automatically identify various models, automatically grab corresponding fixtures and call relevant programs for processing, and integrate technologies such as rapid positioning of body-in-white, laser brazing, welding and handling industrial robots.

With high processing precision and stable quality, it can effectively improve the welding speed and seam quality of automobiles, and realize the automation and intelligence of the body welding production line.

Herolaser implements the core concept of "Herolaser, more suitable for you", and provides customers with suitable products/solutions/services.

The trunk consists of a trunk lid and a rear panel, which is suitable for welding by laser brazing due to the 90-degree angle formed. The traditional trunk welding is carried out by MlG brazing. Since the trunk material is usually galvanized sheet, the low heat output of MlG brazing is required to solve the problem of a large amount of burning of the galvanized layer.

However, the high-speed welding of MlG brazing and the instability of the arc under small current limit its welding efficiency and quality.

In addition, MlG brazing is difficult to form a smooth weld, and the pollution is large. Laser welding is mainly aimed at welding with complex welding forming or sharp changes in the tangential direction of the weld, and the welding forming surface is smooth. Laser brazing has high welding speed, good weld formation, stable quality, less burning loss of galvanized layer, and small deformation.