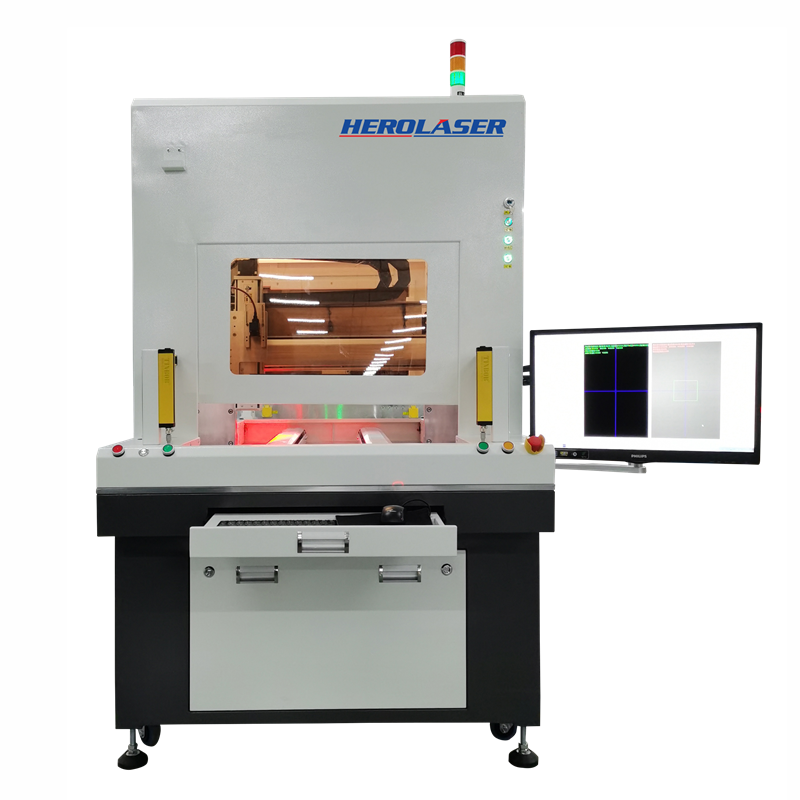

Biyu tashar akai zazzabi Laser soldering inji

Gabatarwar Samfur

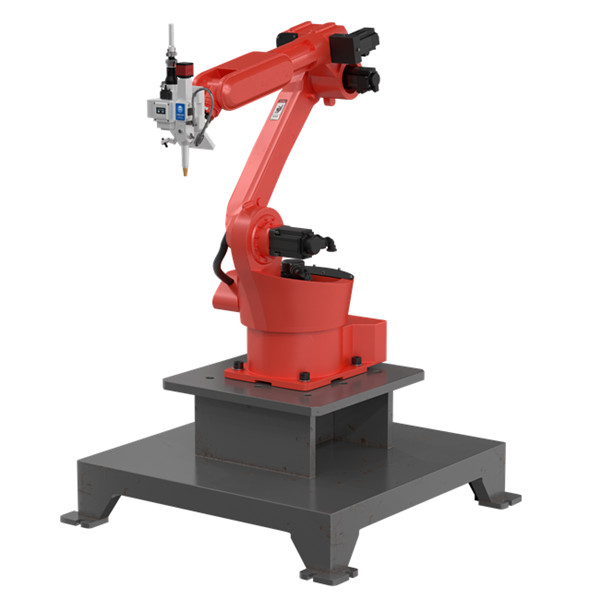

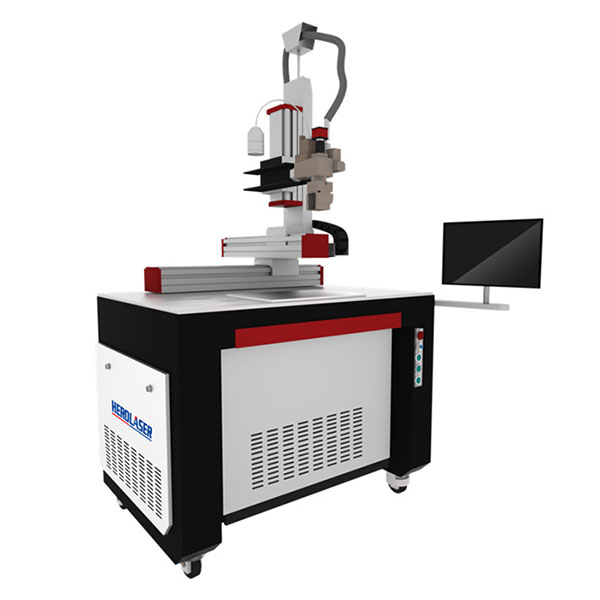

Kayan aikin yana da nau'ikan aiki da yawa da tsarin ciyar da waya ta atomatik ko na'urar ta atomatik daidaitaccen solder manna na'urar zuwa daidaitaccen solder a lokuta daban-daban.Don wasu madaidaicin samfuran waɗanda ba za su iya aiwatarwa tare da reflow soldering da igiyar siyarwar igiyar ruwa ba, injin siyar da Laser zai zama zaɓin abin dogaro don siyar da samfuran ku da aka ba da halayen barga tsarin, ƙimar farashi, babban inganci na soldering da fasahar sarrafa lamba.

| Sigar Fasaha | ||

| A'a. | Abu | Siga |

| 1 | Samfura | ML-WS-XF-ZD2-HW80 |

| 2 | Ƙarfin Laser | 60W-200W |

| 3 | Nau'in Laser | semiconductor |

| 4 | Tsawon hankali mai da hankali | 80/125/160mm(na zaɓi) |

| 5 | Kewayon sarrafa zafin jiki | 60°C-400°C |

| 6 | Daidaiton Tsarin Zazzabi | ± (0.3% karanta + 2°C) (zazzabi na yanayi 23±5°C) |

| 7 | GPS | ICoaxial CCD saka idanu da kuma tabo tin CCD matsayi |

| 8 | Girman kayan aiki | 1100mm*1450*1750mm |

| 9 | Kewayon walda | 250mm*250mm(tashar aiki guda daya) |

| 10 | Ciyarwar bugun jini | 1000mm |

| 11 | Yawan gatura motsi | 6 gaci(X1 Y1 Z1/X2 Y2 Z2) |

| 12 | Maimaituwa | ± 0.02mm |

| 13 | Tsarin kawar da kura | Tsaftace tsafta ta atomatik |

| 14 | Jimlar Nauyi | 350Kg |

| 15 | Jimlar iko | ≤2.5KW |

Mahimman Features

1. Karɓar Laser semiconductor, aiki a cikin hanyar sarrafawa mara lamba.

2. Babu amfani da tip baƙin ƙarfe, yana gudana a cikin ƙananan farashi da sauƙi mai sauƙi.

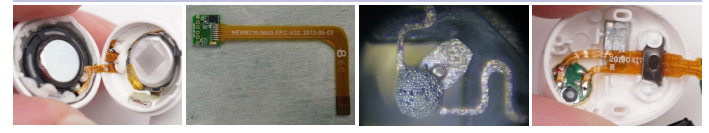

3. Visual sakawa solder batu via Dual hangen nesa aikace-aikace da CCD monitoring tsarin.

4. Laser yana aiki a ƙarƙashin zafin jiki akai-akai ta hanyar rufaffiyar madauki na ciki na kulawar zafin jiki na ainihin lokacin.

5. Za a iya daidaita tabo mai walda don saduwa da girma dabam dabam.

6. Sanya tsarin tsaftace hayaki don cire ragowar konewa daga konewa akan lokaci.

7. Zaɓi don canzawa tsakanin tashar guda ɗaya da yanayin tasha Biyu.

Samfurin Nuni

nemi mafi kyawun farashi

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu