Tube Laser Tej Tshuab (6016 Series)

Khoom Taw Qhia

Technical Parameters

| LUB HOM PHIAJ | THIAB LUB NUMBER |

| Cov khoom siv qauv | ML-CP-6016DQ-GS |

| Laser tso zis zog | 1.5 KW TSI |

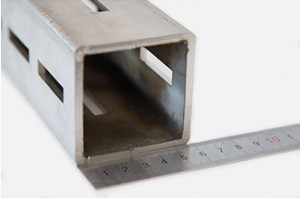

| Chuck clamping ntau yam | Φ20mm ~ Φ160mm, □ 20 ~ □ 110 |

| Qhov siab tshaj plaws ib lub raj hnyav | 60 KG |

| Pub ntev | ≤6300mm (tsis siv neeg pub mis) |

| Qhov ntev ntawm qhov blanking | ≤2500mm (Customizable ntev) |

| Txiav thickness (muaj feem xyuam rau lub zog laser) | Cov pa roj carbon steel ≤6mm;Stainless hlau ≤4mm;Aluminium alloy ≤3mm;Brass ≤ 2 hli; |

| Positioning raug | ≤ ± 0.05 hli |

| Repeatable positioning raug | ≤ ± 0.03 hli |

| Qhov siab tshaj plaws X-axis tshaj tawm | ≤150m / min |

| Qhov siab tshaj plaws Y-axis tshaj tawm | ≤120m / min |

| Qhov siab tshaj plaws z-axis tshaj tawm | ≤ 65m / min |

| B axis siab tshaj plaws tshaj tawm | ≤150RPM |

| Acceleration ntawm spaceflight | 1.2g ua |

| Xav tau hluav taws xob | AC380V ± 5% / 50Hz |

| Lub tshuab siv zog | 6 KW-25 KW |

| Txee Dimensions | 11000 * 2500 * 2300 hli |

| Tshuab hnyav | ≈ 6000KG |

| Kev them nyiaj yug rau cov qauv duab | IGS/SAT/JHB |

Cov yam ntxwv tseem ceeb

1. Cov khoom siv tailing tuaj yeem ncav cuag 0-60mm;

2. Kev ua haujlwm tsawg heev thiab cov nqi kho mob;

3. Lub laser txiav lub taub hau yuav tsis hu rau saum npoo ntawm cov khoom thiab yuav tsis khawb lub workpiece;

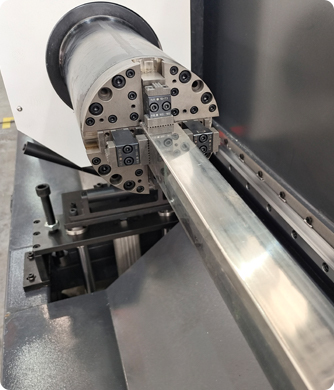

4. Lub hauv ntej chuck clamps tag nrho cov hlab ntsha tsis hloov lub puab tsaig;

5. Kev kub ceev huab cua mus ncig, nrawm nrawm, nrawm nrawm teb, thiab cov ces kaum tsis yooj yim rau hlawv;

6. Cua tshuab ntawm tus Tsov tus tw ntawm daim npav tom qab, cov yeeb nkab phab ntsa huv si, thiab txiav cov plua plav thiab cov pa taws tsawg dua;

7. Qhov siab ntawm lub log txhawb nqa kev pub mis tuaj yeem hloov kho manually, thiab qhov chaw pub mis swb ua ke;

8. High-speed thiab high-zoo laser txiav yuav ua tau rau cov profiles xws li round raj, square tubes, rectangular raj, thiab duav round raj;

9. Cov ntu ntu ntawm cov yeeb nkab yog du yam tsis muaj burrs, tsis muaj slag, tsis muaj blackening, tsis yellowing, thiab tuaj yeem paub qhov kev txiav ntawm ntau yam duab nyuaj.

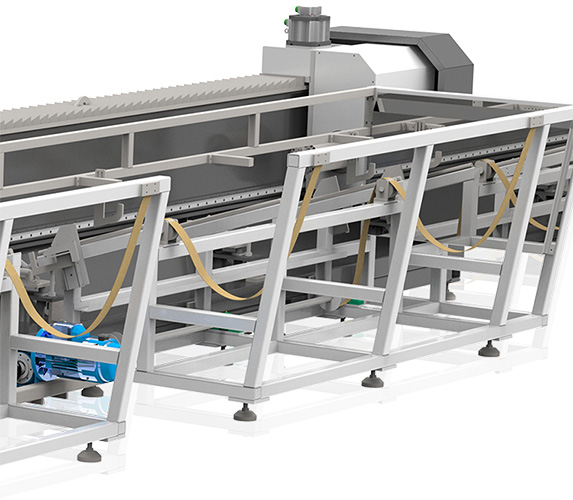

Tsis siv neeg ceev ceev pub mis

Lub cev qauv ntawm cov yeeb nkab txiav tshuab optimized rau ceev ceev tsis siv neeg pub

Qhov kev ncua deb ntawm txoj haujlwm tos thiab txoj haujlwm ua haujlwm yog luv heev, uas yog ntau tshaj 90% sai dua li qhov tsis siv neeg pub noj ceev ntawm cov phooj ywg

Qhov chaw txiav yog huv si thiab tsis muaj qhov tsis xws luag

Cov yeeb nkab txiav ntu yuav tsum du yam tsis muaj burr, slag, blackening thiab daj;Nws yuav tsis tiv nrog cov khoom nto thiab khawb lub workpiece.Nws tuaj yeem yooj yim paub qhov tshuab ntawm tus Tsov tus tw ntawm daim npav tom qab txiav ntau cov duab nyuaj.Cov yeeb nkab phab ntsa huv si thiab txiav cov plua plav thiab cov pa taws tsawg dua

Muaj peev xwm ntawm kev txiav yeeb nkab

Pem hauv ntej chuck tuav tag nrho stroke yam tsis hloov lub claw.Lub chuck nram qab yog tshuab ntawm tus Tsov tus tw, cov yeeb nkab phab ntsa yog huv si, txiav cov plua plav thiab cov pa luam yeeb yog tsawg, lub khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob

Daim duab tseeb ntawm laser yeeb nkab txiav tshuab

Daim ntawv thov Scenario

Kev pub mis yog tsau, qhov siab ntawm lub log txhawb nqa tuaj yeem hloov kho manually, thiab txoj kab nqes blanking yog ua ke nrog zawv zawg;Nws tuaj yeem ua haujlwm siab thiab ua tau zoo laser txiav ntawm lub raj puag ncig, lub raj square, lub raj duab plaub, lub duav raj thiab lwm yam profiles

Video thiab Xov Xwm rau cov khoom no

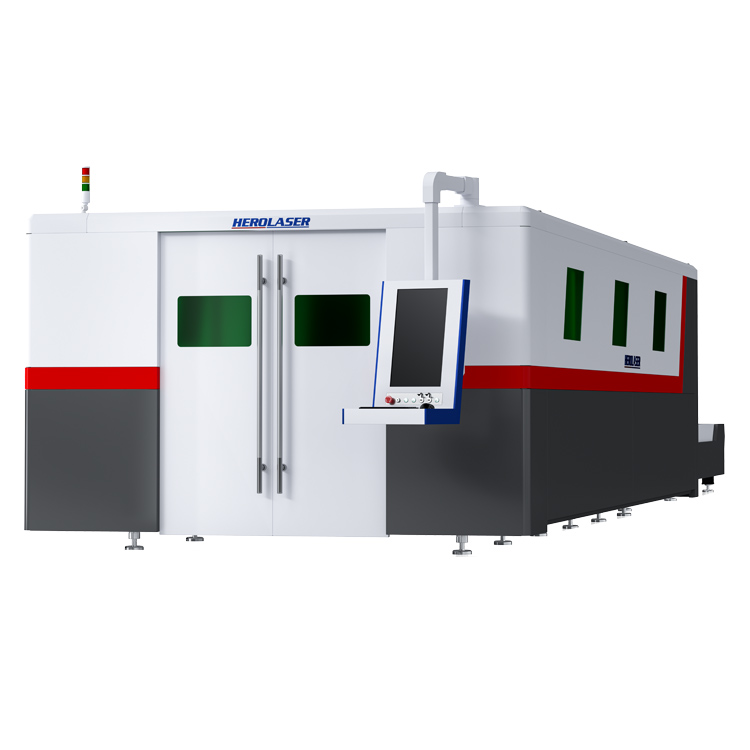

Fiber Laser Tej Tshuab

thaum Lub Plaub Hlis 21, 2022

Fiber Laser Tej Tshuab

thaum Lub Plaub Hlis 21, 2022

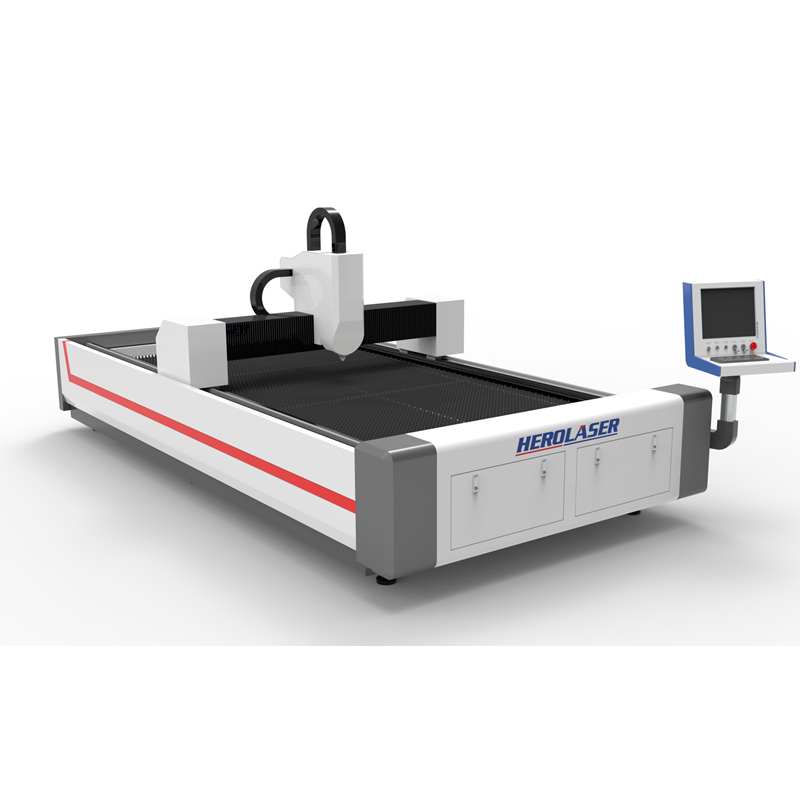

Laser Tej Tshuab

thaum Lub Plaub Hlis 21, 2022

nug tus nqi zoo tshaj plaws

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu