Ob chav chaw nres tsheb qhov kub thiab txias laser soldering tshuab

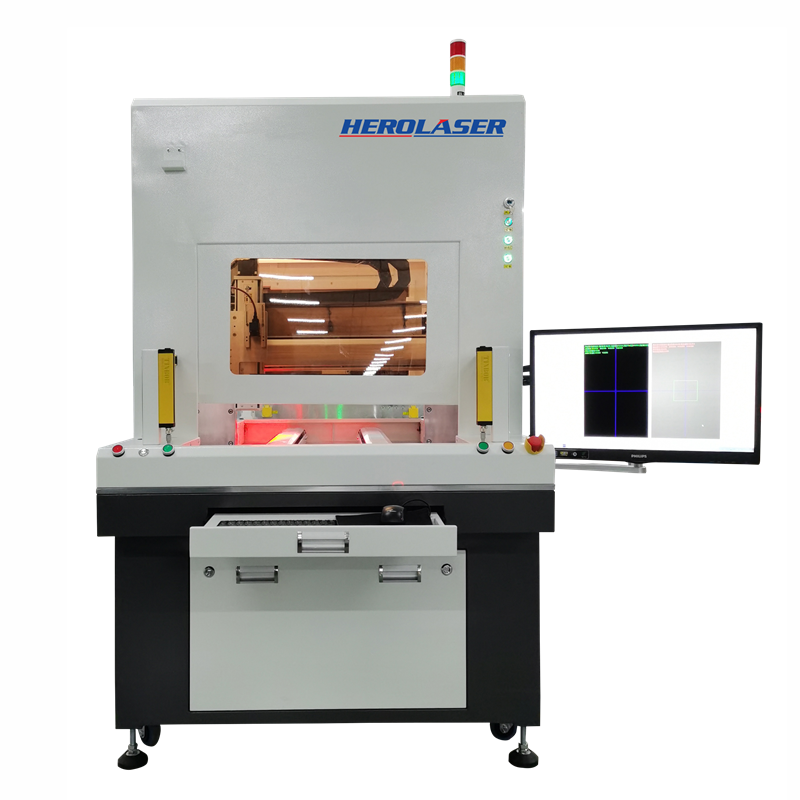

Khoom Taw Qhia

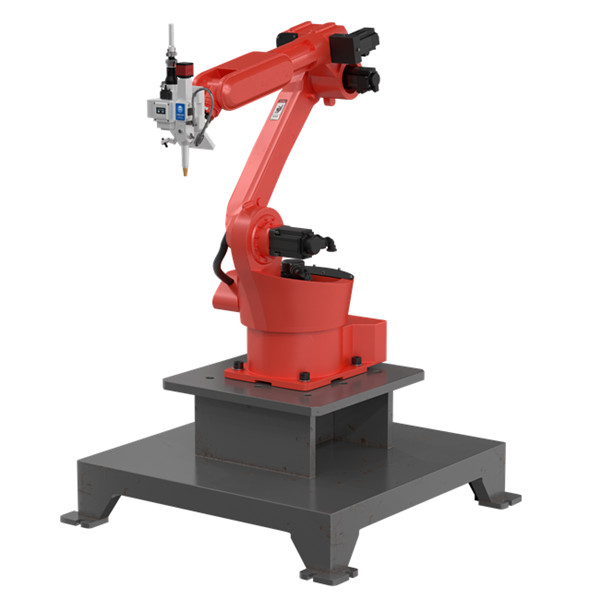

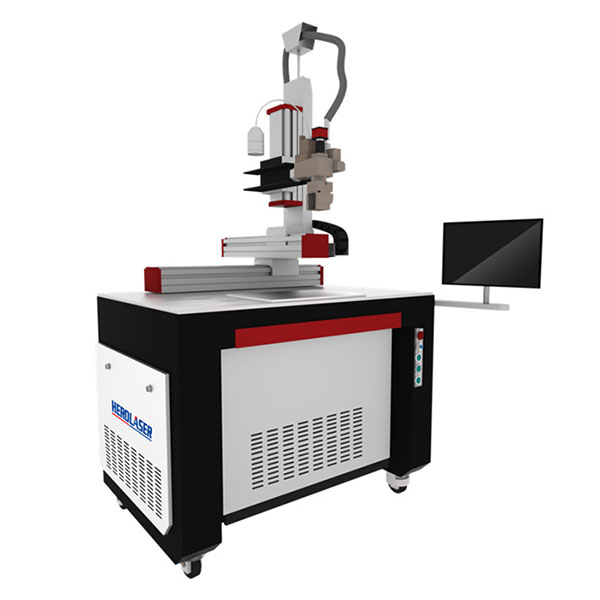

Cov cuab yeej muaj ntau hom kev ua haujlwm thiab tsis siv neeg xaim pub mis lossis tsis siv neeg precision solder paste dispensing ntaus ntawv kom zoo kawg nkaus solder nyob rau hauv ntau zaus.Rau qee yam khoom lag luam uas tsis tuaj yeem ua cov txheej txheem nrog reflow soldering thiab yoj siv lub tshuab, laser soldering tshuab yuav yog koj qhov kev xaiv txhim khu kev qha rau solder koj cov khoom muab cov yam ntxwv ntawm cov qauv ruaj khov, tus nqi-zoo, kev ua haujlwm siab ntawm soldering thiab kev tswj cov lej.

| Technical Parameter | ||

| Tsis muaj. | Yam khoom | Parameter |

| 1 | Qauv | ML-WS-XF-ZD2-HW80 |

| 2 | Laser zog | 60W-200W |

| 3 | Laser hom | semiconductor |

| 4 | Ua kom pom tseeb qhov ntev | 80/125/160 hli(xaiv tau) |

| 5 | Kev tswj qhov ntsuas kub | 60 ° C-400 ° C |

| 6 | Temperature System Qhov tseeb | ± (0.3% nyeem ntawv + 2 ° C) (ambient kub 23 ± 5 ° C) |

| 7 | GPS | ICoaxial CCD saib xyuas thiab qhov chaw tin CCD positioning |

| 8 | Cov khoom siv loj | 1100mm * 1450mm * 1750mm |

| 9 | Vuam ntau | 250mm * 250 hli(ib qho chaw ua haujlwm) |

| 10 | Pub mob stroke | 1000 hli |

| 11 | Tus naj npawb ntawm kev txav axes | 6ax ib(X1 Y1 Z1 / X2 Y2 Z2) |

| 12 | Rov ua dua | ± 0.02 hli |

| 13 | Kev tshem tawm plua plav system | Tsis siv neeg soot purification system |

| 14 | Qhov hnyav tag nrho | 350 Kg |

| 15 | Tag nrho lub zog | ≤ 2.5KW |

Cov yam ntxwv tseem ceeb

1. Txais yuav semiconductor laser, ua hauj lwm nyob rau hauv txoj kev tsis sib cuag.

2. Tsis muaj kev noj ntawm cov hlau taub hau, khiav hauv tus nqi qis thiab kev saib xyuas yooj yim.

3. Visual positioning solder point ntawm Dual vision application thiab CCD xyuas qhov system.

4. Laser yog ua nyob rau hauv qhov kub thiab txias nyob rau hauv lub kaw-voj tawm tswv yim ntawm real-time kub xyuas.

5. Qhov chaw vuam tuaj yeem hloov kho kom tau raws li qhov sib txawv ntawm qhov sib txawv.

6. Siv lub tshuab nqus pa kom tshem tawm cov hluav taws kub nyhiab los ntawm kev sib tsoo.

7. yeem hloov ntawm ib qho chaw nres tsheb thiab Ob chav chaw nres tsheb hom.

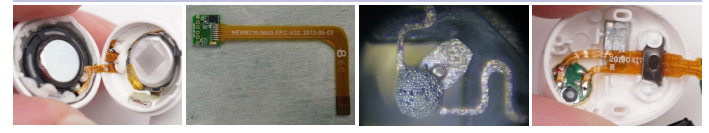

Sample Display

nug tus nqi zoo tshaj plaws

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu