Igwe ịgbado ọkụ Laser Obere Handheld

Okwu Mmalite ngwaahịa

Igwe ịgbado ọkụ nke I-welder Mini SE na-anabata ọgbọ kachasị ọhụrụ nke fiber laser ma kwadebere ya na isi ịgbado ọkụ nke onwe ya, nke na-ejuputa oghere nke ịgbado ọkụ aka na ụlọ ọrụ akụrụngwa laser.Na uru nke ngwa ngwa ịgbado ọkụ ọsọ na enweghị consumables, ọ nwere ike zuru okè dochie omenala argon arc ịgbado ọkụ, electric ịgbado ọkụ na ndị ọzọ Filiks mgbe ịgbado ọkụ mkpa igwe anaghị agba nchara efere, ígwè efere, galvanized efere na ndị ọzọ metal ihe.Aka-ejide laser ịgbado ọkụ igwe nwere ike n'ọtụtụ ebe na mgbagwoju na oge ịgbado ọkụ Filiks na kabinet kichin na ime ụlọ ịwụ, steepụ elevator, shelf, oven, igwe anaghị agba nchara ụzọ na window guardrail, nkesa igbe, igwe anaghị agba nchara ụlọ na ndị ọzọ ọrụ.

Nka nka

| Ihe | Oke |

| Ike Laser | 1000W 1500W |

| Ogologo ogologo | 1070NM |

| Ogologo eriri | Ọkọlọtọ 10m, 15m kacha ogologo akwadoro (nwere ike ịhazi) |

| Ụdị ọrụ | Na-aga n'ihu / Modulation |

| Oke nke ịgbado ọkụ ọsọ | 0 ~ 120mm / s |

| Igwe mmiri jụrụ oyi | Okpomọkụ ụlọ ọrụ na-adị n'otu oge njikwa ọkụ abụọ |

| Oke okpomọkụ gburugburu na-arụ ọrụ | 15-35 ℃ |

| Oke iru mmiri na-arụ ọrụ gburugburu | <70% enweghị condensation |

| Ndụmọdụ maka ịdị arọ ịgbado ọkụ | 0.5-3 mm |

| Ihe ndị chọrọ maka Welds | <0.3mm |

| Voltaji na-arụ ọrụ | 220V |

| Nha Igwe | 35*28*18(anụ ọhịa) |

| Ibu nke Igwe | 150KG |

Ndepụta akụrụngwa

| Mba. | Isi ihe | Nkọwapụta | Logo | Ọnụọgụ | Okwu |

| 1 | Isi iyi Laser | Helaser | 1 | ||

| 2 | Sistemụ jụrụ oyi | Helaser | 1 | ||

| 3 | Ihuenyo mmetụ aka | 7 anụ ọhịa | Helaser | 1 | |

| 4 | Sistemụ njikwa | Helaser | 1 | ||

| 5 | Isi welded | Helaser | 1 | ||

| 6 | Ụlọ ọrụ | Helaser | 1 | ||

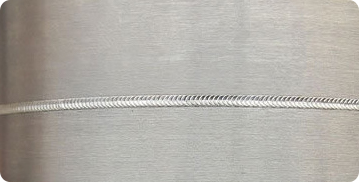

| 7 | Ọla kọpa | Helaser | 5 | ||

| 8 | Igwefoto nchekwa | Helaser | 5 | ||

| 9 | Ihe ntanetị waya | Helaser | 1 |

Ihe oriri na ngwa ngwa ngwa ngwa

| Mba. | Ihe | Logo | Ebe Mmalite |

| 1 | Ọla kọpa | Helaser | Heyuan, Guangdong |

| 2 | Igwefoto nchekwa | Helaser | Heyuan, Guangdong |

| 3 | Lens na-elekwasị anya | Helaser | Heyuan, Guangdong |

| 4 | oghere oghere | Helaser | Heyuan, Guangdong |

Atụmatụ isi

1. Enwere ike ịrụ ọrụ mgbe ọzụzụ dị mfe;

2.One-oge ịkpụzi, ị nwere ike weld mara mma ngwaahịa na-enweghị nna ukwu;

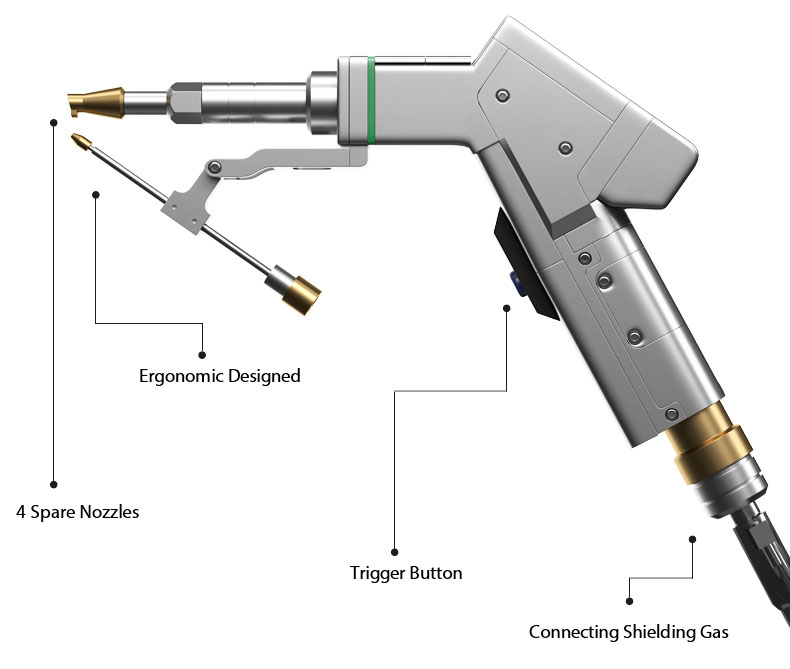

3.Light na mgbanwe nke WOBBLE laser isi n'aka,;

4.Any akụkụ nke workpiece nwere ike welded;

5.The ịgbado ọkụ bụ oru oma, mma, ike-azọpụta na gburugburu ebe obibi enyi na enyi.

6. Obere na ìhè, dị mfe ịkwaga (150KG)

7. Ọ nwere ike ịchekwa ego nke 3-10 welders

8. Ọsọ ịgbado ọkụ bụ ugboro iri ngwa ngwa karịa omenala

9. Otu oge ịkpụzi, enweghị oji

10. Ngwongwo ahụ mara mma, ọ dịghị mkpa ka a na-egbuke egbuke

11. WOBBLE teknụzụ ịgbado ọkụ

12. Igwe mmiri a na-arụ n'ime ya, jikọtara ya na friji okpomọkụ mgbe niile

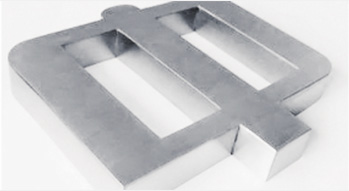

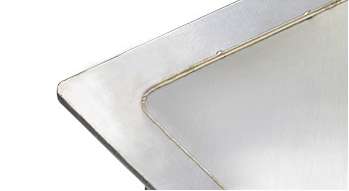

Mgbado ọkụ fillet

ịgbado ọkụ n'apata ụkwụ

Ịgbado ọkụ akwa akwa

Ịgbado ọkụ stitch

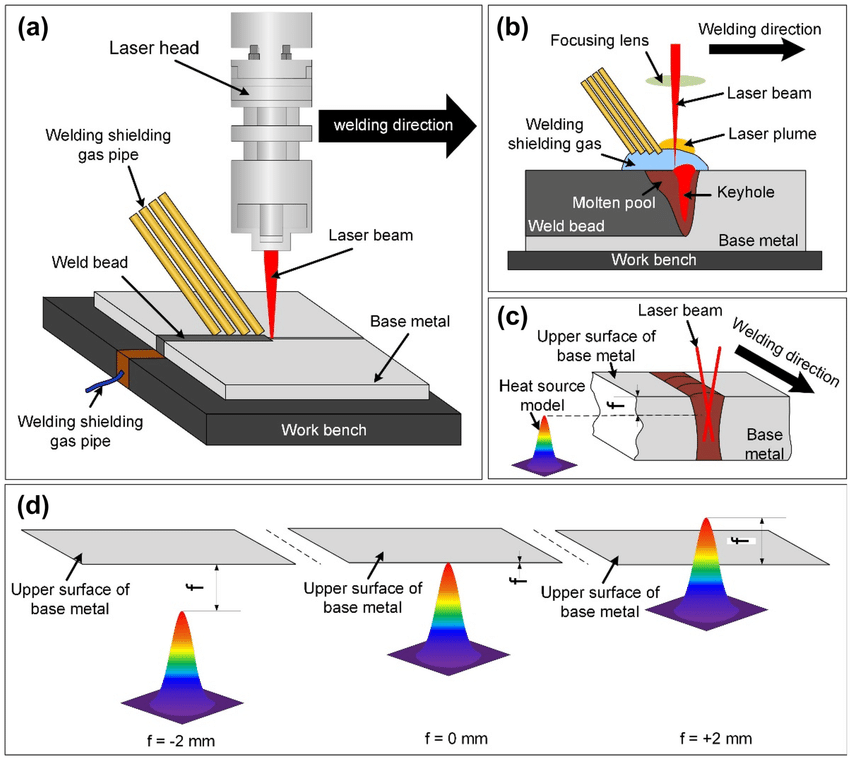

Nchọpụta onwe onye na mmepe nke isi ịgbado ọkụ wobble

1. The wobble ịgbado ọkụ nkwonkwo onwe mepụtara adopts siwing ịgbado ọkụ mode;

2. Enwere ike ịhazi obosara ntụpọ ìhè;

3. The ịgbado ọkụ kpatara ndidi dị ike, nke na-eme maka mwepu nke obere laser ịgbado ọkụ ntụpọ, gbasaa ndidi nso na weld obosara nke esichara akụkụ, na-enweta mma weld akpụ.

Ihe ngosi ngwa

Igwe ịgbado ọkụ laser ejiri aka a dabara adaba maka ịgbado ọkụ nke ọla edo, ọla ọcha, titanium, nickel, tin, ọla kọpa, aluminom na ọla ndị ọzọ na ihe alloy ya, nwere ike nweta otu ịgbado ọkụ ahụ ziri ezi n'etiti ọla na ọla dị iche iche, ejirila ya na akụrụngwa ikuku. , shipbuilding, instrumentation, n'ibu na eletriki ngwaahịa, ụgbọala na ndị ọzọ ọrụ.

Nka nka nka n'ime igwe Laser na-ejide obere aka

| Ihe | Oke |

| Ike Laser | 1000W 1500W |

| Ogologo ogologo | 1070NM |

| Ogologo eriri | Ọkọlọtọ 10m, 15m kacha ogologo akwadoro (nwere ike ịhazi) |

| Ụdị ọrụ | Na-aga n'ihu / Modulation |

| Oke nke ịgbado ọkụ ọsọ | 0 ~ 120mm / s |

| Igwe mmiri jụrụ oyi | Okpomọkụ ụlọ ọrụ na-adị n'otu oge njikwa ọkụ abụọ |

| Oke okpomọkụ gburugburu na-arụ ọrụ | 15-35 ℃ |

| Oke iru mmiri na-arụ ọrụ gburugburu | <70% enweghị condensation |

| Ndụmọdụ maka ịdị arọ ịgbado ọkụ | 0.5-3 mm |

| Ihe ndị chọrọ maka Welds | <0.3mm |

| Voltaji na-arụ ọrụ | 220V |

| Nha Igwe | 35*28*18(anụ ọhịa) |

| Ibu nke Igwe | 150KG |

Nyocha ike ịgbado ọkụ laser

| Ike laser | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Ihe onwunwe | ọkpụrụkpụ | |||||||||

| Igwe anaghị agba nchara | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Carbon ígwè | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Aluminom | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

Eserese eserese nke usoro ịgbado ọkụ laser:

Ụdị dị iche iche nke ịgbado ọkụ laser:

| Ụdị laser | Ogologo ogologo | Ụdị mmepụta | Ngwa |

| CW fiber laser | 1070nm | Na-aga n'ihu | Ịgbado ọkụ na-adịte aka/na-aga n'ihu nke otu igwe Modulated pulse spot welding |

| YAG laser | 1064nm | Pulse | Ngwa ịgbado ọkụ/weld nke otu igwe |

| QCW eriri laser | 1070nm | Pulse/na-aga n'ihu | Mgbado ọkụ igwe ntụpọ / ịgbado ọkụ na-aga n'ihu |

| Semiconductor laser | 808nm,915nm, 980nm | Pulse/na-aga n'ihu | Plastic Welding/Laser soldering |

HEROLASER nwere ọgụgụ isi Laser nhazi akụrụngwa ngwaahịa katalọgụ

Maka nnukwu ịzụrụ ma ọ bụ ngwaahịa ahaziri ahazi, biko kpọtụrụ ndị ahịa n'ịntanetị, ma ọ bụhapụ ozi.

Ị nwekwara ike izipu ozi-esales@herolaser.net.

rịọ maka ọnụahịa kacha mma

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu