Igwe eji agbado ọkụ na-emezi YAG Laser

Okwu Mmalite ngwaahịa

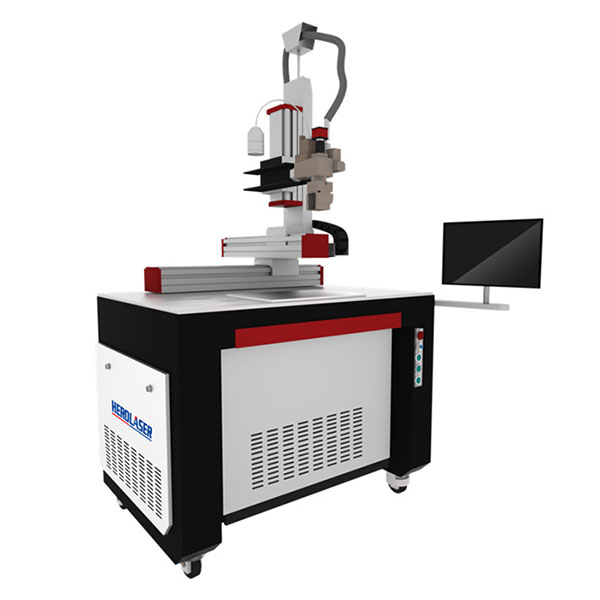

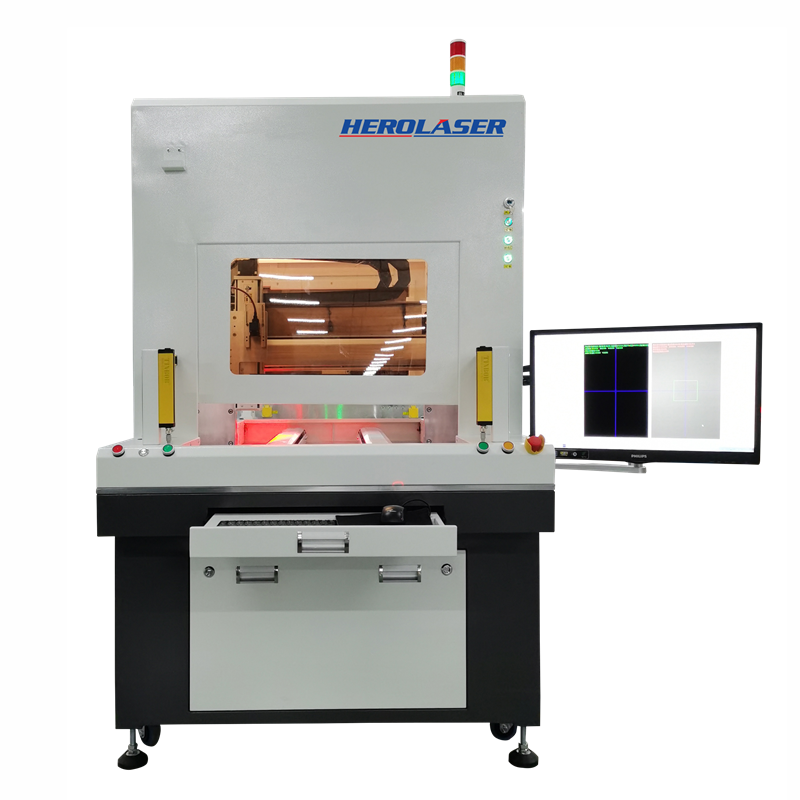

Herolaser ebu na-arụkwa laser ịgbado ọkụ igwe usoro bụ pụrụ iche maka ebu ụlọ ọrụ na-arụ ọrụ, ihe nlereanya a raara nye dochie omenala argon welder maka ịrụkwa nkenke ebu.A na-ebubata ihe niile dị mkpa nke igwe a.Ngwa ngwanrọ na-arụ ọrụ na-eji nnukwu ihuenyo LCD ma gosipụta interface asụsụ dị iche iche, ọ dị mfe ma dị mfe iji maka onye ọrụ.Ụdị nhazi nhazi ọtụtụ, nwekwara ike ịme mmemme site na ndị ọrụ, ọrụ ebe nchekwa na-adịgide adịgide, ọdabara na ihe dị iche iche.

Ejiri usoro nlele microscope pụrụ iche, mmụba 10x;Enwere ngwaọrụ nchekwa ihe nzacha eletrọnịkị dị elu iji kpuchido anya onye ọrụ na mmebi laser, belata ike ọgwụgwụ anya onye ọrụ ma melite arụmọrụ ọrụ.

Usoro nchebe argon na-emekọrịta ihe na njikwa microcomputer dị n'ime nwere ike igbochi weld ka ọ bụrụ oxidized ma mee ka ịgbado ọkụ ahụ sie ike ma mara mma;Enwere ike ịchekwa argon ruo n'ókè kachasị ukwuu site n'inwe njikwa synchronous na ikuku laser

Mmiri mmiri nke igwe ịgbado ọkụ laser laser nwere ike ikpo ọkụ ma mee ka igwe ahụ dị jụụ, ma nyochaa okpomọkụ mmiri ozugbo.Ọ nwere ọnọdụ okpomọkụ / mgbasa ozi mgbe niile

The laser usu kabinet nwere ike n'ụzọ doro anya na-edebe ngwaahịa n'ọnọdu na ịgbado ọkụ mmetụta dị ka red ìhè egosi

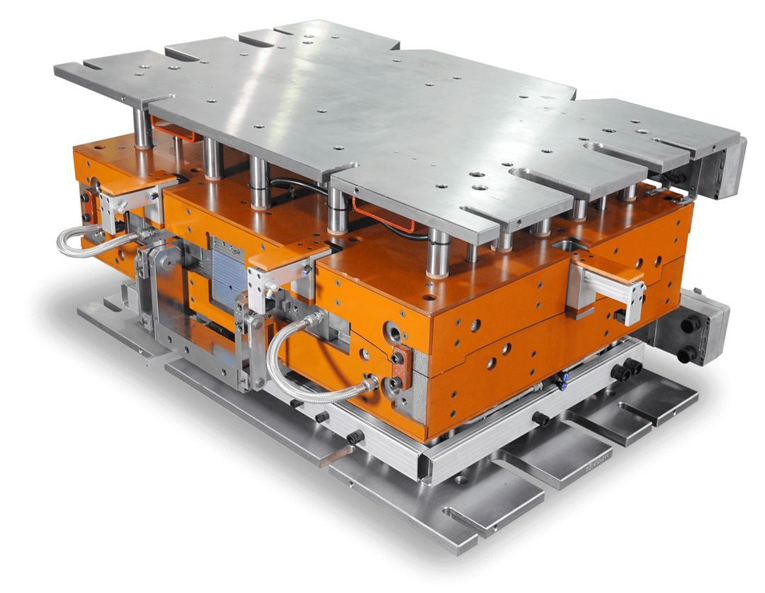

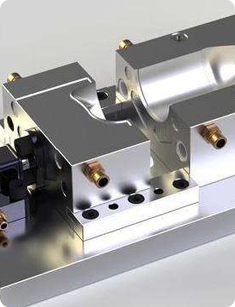

The isi igwe workbench na ebe a na-etinye ịgbado ọkụ workpiece bụ adaba maka laser weld workpiece.

Nka nka

| Nlereanya: | ML-WY-BP-DB-W200 | ML-WY-BP-DB-W400 |

| 3-axis ọrịa strok nke bench ọrụ | X=300mm, Y=200mm(X,Enwere ike iji aka dozie Y yana a ga-ebuli axis z) | |

| Ịkwado bench ọrụ | ≤200KG | |

| Ịnye ọkụ | 220V± 10%/50Hz ma ọ bụ 380V±10%/50Hz | |

| Ihe ngosi laser | ||

| Ụdị laser | Nd:YAG pulse | |

| Ndozi nso nke ntụpọ ọkụ | 0.1~0.3mm | |

| Ogo ntụpọ ọkụ | 0.2-3.0mm | |

| Ogologo ogologo nke laser | 1064nm | |

| Obosara usu | 0.5~25ms | |

| Ike laser kachasị | 200W | 400W |

| Ugboro ugboro | ≤50Hz | |

| Ogologo elekwasị anya na mmepụta laser | 80mm / 100mm / 120mm (nhọrọ) | |

| Laser jụrụ oyi | Mmiri jụrụ oyi | |

| Sistemụ nlele | Microscope (360° nwere ike idozi) | |

| gas nchebe | Otu ahịrị (xenon) | |

| Oke solder | ||

| Dayameta waya ịgbado ọkụ | 0.1mm~0.8mm | |

Atụmatụ isi

1. Okpomọkụ emetụtara mpaghara bụ obere, obere deformation maka nkenke ebu.

2. Welding omimi bụ nnukwu, ịgbado ọkụ ike.Ngwakọta zuru oke, enweghị nrụzi akara.Ọ dịghị dimple phenomena na ijikọta ọnọdụ nke ntule akụkụ na ntopute akụkụ nke ọdọ mmiri a wụrụ awụ soluble ihe.

3. Ọnụego oxidation dị ala, agba nke akụkụ nhazi adịghị emebi.

4. Ọ dịghị stomata ma ọ bụ ájá oghere n'anya mgbe ịgbado ọkụ.

5. Enwere ike ịhazi akụkụ nke ịgbado ọkụ, karịsịa maka polishing chọrọ nke nrụzi ebu.

6. Akụkụ nhazi nwere ike iru 50 ruo 60 Rockwell hardness.

Ọ dịghị deformation nke ịgbado ọkụ anwụ

Ebe okpomọkụ emetụtara dị ntakịrị, nke na-agaghị eduga na nrụrụ nke nkenke na-anwụ anwụ, ọ dịghịkwa ịda mbà n'obi na nkwonkwo n'etiti akụkụ convex nke ihe a wụrụ awụ na ọdọ mmiri a wụrụ awụ na matrix.

● Ọnụego oxidation dị ala na workpiece agaghị agbanwe agba mgbe ịgbado ọkụ

● Ebe a na-ekpo ọkụ dị ntakịrị, na akụkụ ndị a na-arụ ọrụ agaghị emezi

● A gaghị enwe oghere ma ọ bụ trachoma mgbe ịgbado ọkụ gachara

● Mgbe agbadochara ya, enwere ike ịdepụta ya n'emebighị ihe ọ pụtara

Ihe ngosi ngwa

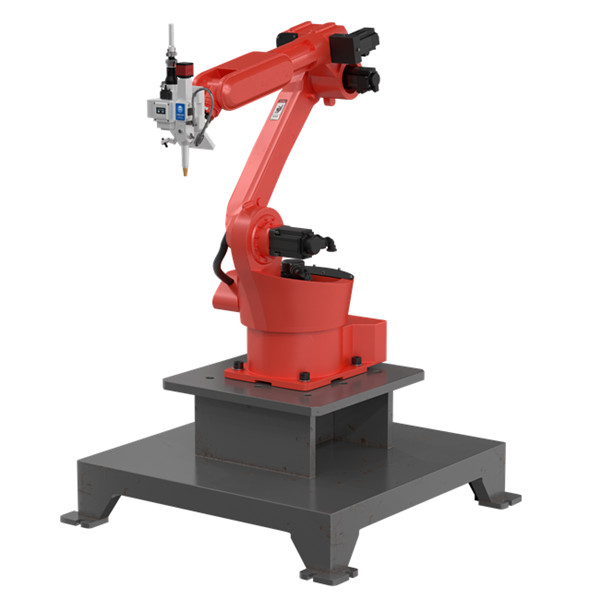

Ụlọ ọrụ ebu

Ịrụ ígwè

Imepụta igwe

Vidiyo na akụkọ maka ngwaahịa a

Igwe ịgbado ọkụ laser

na Eprel 21,2022

Igwe ịgbado ọkụ laser

na Eprel 21,2022

Igwe ịgbado ọkụ laser

na Eprel 21,2022

rịọ maka ọnụahịa kacha mma

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu