Igwe ịgbado ọkụ laser ejiri aka (ọkọlọtọ)

Okwu Mmalite ngwaahịa

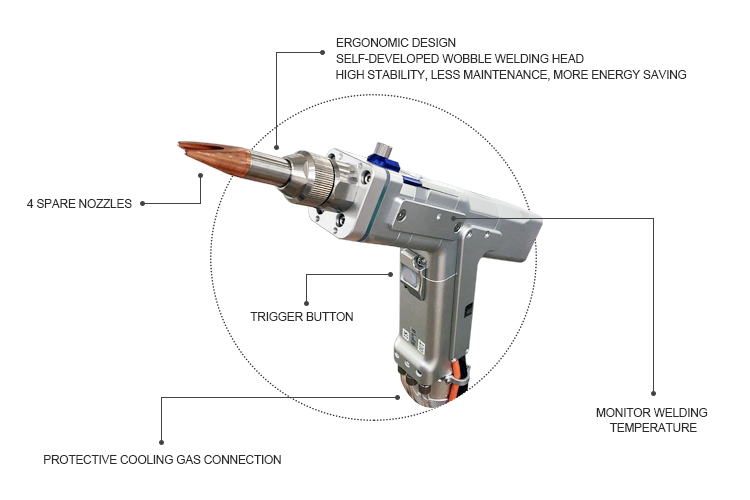

N'ịbụ nke Herolaser mepụtara ya nke mbụ, igwe ịgbado ọkụ na-eji aka na-abata na ọgbọ ọhụrụ nke fiber laser, onye na-enye waya akpaka na isi mgbado ọkụ nke emepụtara ọhụrụ, nke na-eme ka ọ bụrụ ihe pụrụ iche iji mejupụta oghere nke ahịa ịgbado ọkụ laser ejiri aka.

Na mfe ntuziaka, igwe na-arụ ọrụ n'ime a zuru okè ịgbado ọkụ ọdọ mmiri na a ezigbo ego nke oge na-achọ ọ dịghị consumables electrode, nke n'ụzọ zuru okè na-anọchi nhazi ụzọ omenala ntuziaka metal arc ịgbado ọkụ igwe n'elu mkpa igwe anaghị agba nchara, ígwè efere na galvanized efere.Ekele ya ịgbado ọkụ mgbanwe na oge ufodu shapes nke workpieces, igwe na ọtụtụ-eji na kichin cabinets na arịa, steepụ handrails na elevators, ụlọ ahịa racks, oven, ọnụ ụzọ na window nche Ogwe, ike nkesa igbe, igwe anaghị agba nchara ngwá ụlọ na ndị ọzọ ọrụ.

Igwe ahụ na-anabata atụmatụ enyi na teknụzụ kwalitere, ma e jiri ya tụnyere ngwa ịgbado ọkụ ọdịnala, na-eme ka ndị welder na-arụ ọrụ nke ọma, nchekwa, nchekwa ike na ụzọ enyi na gburugburu ebe obibi.Ọsọ ịgbado ọkụ bụ ugboro 3 ruo 10 ngwa ngwa karịa mgbe ọ na-abịa na aka ma kpuchie mmefu ego gị nke ukwuu.Igwe ịgbado ọkụ nke aka Herolaser - mee ka ndị welder hụ ọrụ ha n'anya karịa.

Nka nka

| Ike Laser | 1000W/ 1500W/ 2000W/ 3000W |

| Ogologo ogologo nke laser | 1070nm |

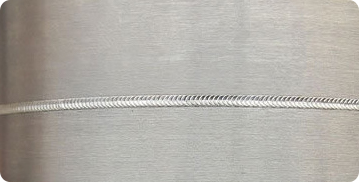

| Ogologo eriri | Nhazi ọkọlọtọ: 10M, nkwado kachasị: 15m |

| Ụdị ọrụ | Na-aga n'ihu / modulation |

| Welding igwe ọsọ nso | 0-120 mm / s |

| Igwe mmiri oyi | Igwe mmiri thermostatic ụlọ ọrụ |

| Okpomọkụ gburugburu | 15-35 ℃ |

| iru mmiri gburugburu | <70% enweghị condensation |

| Ọkpụrụkpụ ịgbado ọkụ | 0.5-3 mm |

| Achọrọ oghere | ≤0.5mm |

| Voltaji na-arụ ọrụ | AC220V |

| Nha | 1100mm x 570mm x 1180mm |

| Ibu | 220kg |

Atụmatụ isi

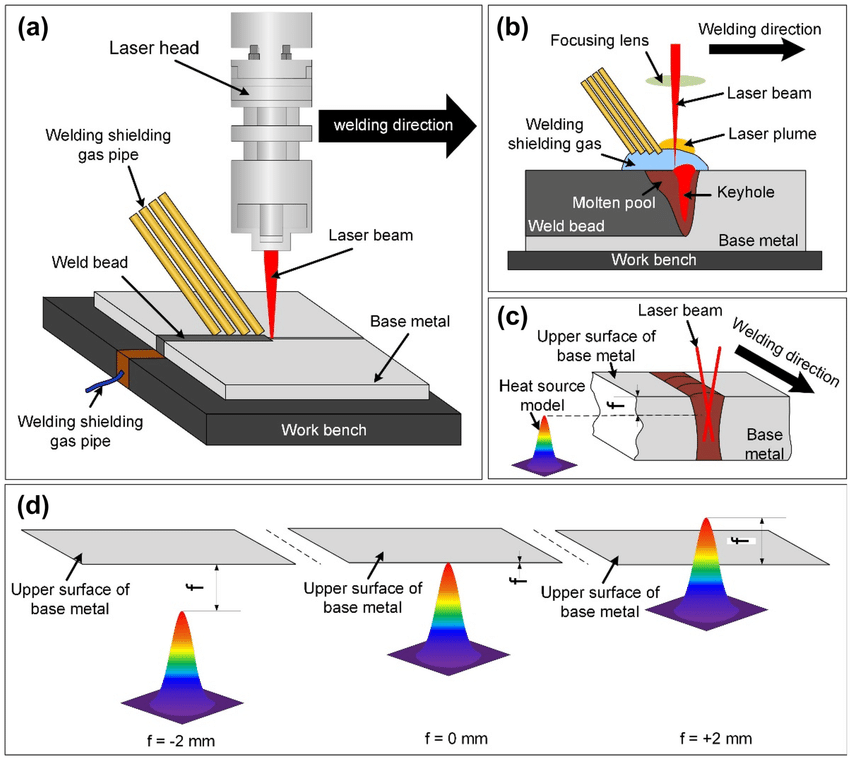

Teknụzụ ịgbado ọkụ ọkụ nke nkwonkwo welded

The wobble ịgbado ọkụ nkwonkwo na-onwe mepụtara, na siwing ịgbado ọkụ mode, mgbanwe ntụpọ obosara na ike ịgbado ọkụ kpatara ndidi, nke na-eme maka mwepu nke obere laser ịgbado ọkụ ntụpọ, gbasaa ndidi nso na weld obosara nke nhazi akụkụ, na-enweta mma weld akpụ akpụ. .

1. Mma weld formability na elu-edu ntụpọ ịgbado ọkụ

2. The fuselage na laser isi nwere obere ihe achọrọ maka ike laser

3. A ga-agbasawanye ebe a na-enye ohere nke obosara weld, na weld ga-adị mma na-enweghị nrụrụ

4. Magburu onwe aluminum alloy bonding ikike, elu-edu nhazi repeatability na nkwụsi ike

WOBBLE Laser handheld head head, ìhè na mgbanwe, nwere ike ịgbado akụkụ ọ bụla nke workpiece, na-eme ka ịgbado ọkụ na-arụ ọrụ nke ọma, nchekwa, ike na-azọpụta na gburugburu ebe obibi enyi na enyi.

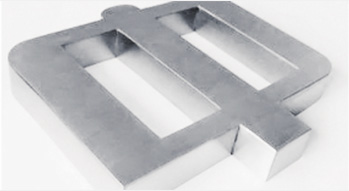

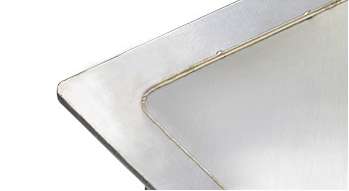

Mgbado ọkụ fillet

ịgbado ọkụ n'apata ụkwụ

Ịgbado ọkụ akwa akwa

Ịgbado ọkụ stitch

Atụmatụ igwe ịgbado ọkụ ejiri aka jụrụ mmiri

Wuru na-na dual-okpomọkụ dual-control Industrial chiller.constant okpomọkụ ụkpụrụ na okpomọkụ dissipation, iji hụ na okpomọkụ dissipation nke isi ngwa anya circuit components.With fiber laser, kwụsiri ike na ịrụ ọrụ nke ọma.

Ihuenyo mmetụ agbakwunyere

arụmọrụ panel ngosi ọtụtụ asụsụ, dị mfe nghọta, enweghị ahụmịhe achọrọ, ọzụzụ n'efu, dị mfe ịmụta

fuselage siri ike

A na-eji fuselage mee ihe siri ike, nke na-adịgide adịgide, ịdị mma a pụrụ ịdabere na ya, na-edozi obere ma kwụsie ike

10-15m eriri eriri anya

A na-ahazi eriri eriri anya 10-15m n'etiti isi laser na onye ọbịa, nke dị mma maka ịgbado ọkụ mkpanaka na ngwa mgbanwe.

Ihe ngosi ngwa

Igwe ịgbado ọkụ laser ejiri aka a dabara adaba maka ịgbado ọkụ nke ọla edo, ọla ọcha, titanium, nickel, tin, ọla kọpa, aluminom na ọla ndị ọzọ na ihe alloy ya, nwere ike nweta otu ịgbado ọkụ ahụ ziri ezi n'etiti ọla na ọla dị iche iche, ejirila ya na akụrụngwa ikuku. , shipbuilding, instrumentation, n'ibu na eletriki ngwaahịa, ụgbọala na ndị ọzọ ọrụ.

Nyocha ike ịgbado ọkụ laser

| Ike laser | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Ihe onwunwe | ọkpụrụkpụ | |||||||||

| Igwe anaghị agba nchara | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Carbon ígwè | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Aluminom | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

Eserese eserese nke usoro ịgbado ọkụ laser:

Ụdị dị iche iche nke ịgbado ọkụ laser:

| Ụdị laser | Ogologo ogologo | Ụdị mmepụta | Ngwa |

| CW fiber laser | 1070nm | Na-aga n'ihu | Ịgbado ọkụ na-adịte aka/na-aga n'ihu nke otu igwe Modulated pulse spot welding |

| YAG laser | 1064nm | Pulse | Ngwa ịgbado ọkụ/weld nke otu igwe |

| QCW eriri laser | 1070nm | Pulse/na-aga n'ihu | Mgbado ọkụ igwe ntụpọ / ịgbado ọkụ na-aga n'ihu |

| Semiconductor laser | 808nm, 915nm,980nm | Pulse/na-aga n'ihu | Plastic Welding/Laser soldering |

HEROLASER nwere ọgụgụ isi Laser nhazi akụrụngwa ngwaahịa katalọgụ

Maka nnukwu ịzụrụ ma ọ bụ ngwaahịa ahaziri ahazi, biko kpọtụrụ ndị ahịa n'ịntanetị, ma ọ bụhapụ ozi.

Ị nwekwara ike izipu ozi-esales@herolaser.net.