I-Series Water Cooling Handheld Laser Welding Machine

Product Introduction

I-welder Mini SE laser welding machine adopts the latest generation of fiber laser and is equipped with self-developed wobble welding head, which fills the gap of handheld welding in the laser equipment industry. With the advantages of fast welding speed and no consumables, it can perfectly replace traditional argon arc welding, electric welding and other processes when welding thin stainless steel plates, iron plates, galvanized plates and other metal materials. Hand-held laser welding machine can be widely used in complex and irregular welding processes in cabinet kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries.

Core Features

1.Can be operated after simple training;

2.One-time molding, you can weld beautiful products without a master;

3.Light and flexible of the WOBBLE hand-held laser head,;

4.Any part of the workpiece can be welded;

5.The welding is efficient, safe, energy-saving and environmentally friendly.

6. Small and light, easy to move (150KG)

7. It can save the cost of 3-10 welders

8. The welding speed is 10 times faster than the traditional

9. One-time molding, no blackening

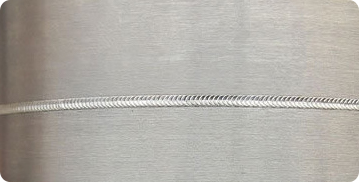

10. The welds are beautiful and do not need to be polished

11. WOBBLE welding technology

12. Built-in water tank, integrated constant temperature refrigeration

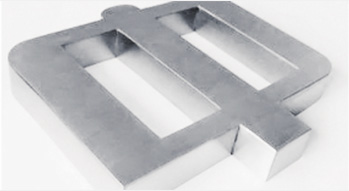

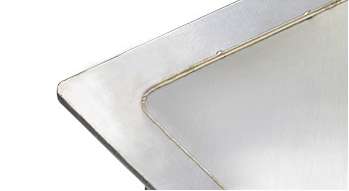

Fillet welding

Lap welding

Tailor welding

Stitch welding

Technical Parameters

| Item | Parameter |

| Laser Power | 1000W 1500W |

| Wavelength | 1070NM |

| Fiber Length | Standard 10m, Longest Supported 15m(Customizable) |

| Operation Mode | Continuous / Modulation |

| Range of Welding Speed | 0~120mm/s |

| Cooling Water Machine | Industrial Constant Temperature Dual Temperature Dual Control |

| Operating Ambient Temperature Range | 15~35℃ |

| Working Environment Humidity Range | <70% no condensation |

| Recommendations for Welding Thickness | 0.5-3mm |

| Requirements for Welds | <0.3mm |

| Working Voltage | 220V |

| Size of Machine | 35*28*18(inch) |

| Weight of Machine | 150KG |

Application Scenarios

This handheld laser welding machine is suitable for welding of gold, silver, titanium, nickel, tin, copper, aluminum and other metal and its alloy material, can achieve the same precision welding between metal and dissimilar metals, has been widely used in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, automotive and other industries.

Mini Handheld Laser Welding Machine Technical Parameters

| Item | Parameter |

| Laser Power | 1000W 1500W |

| Wavelength | 1070NM |

| Fiber Length | Standard 10m, Longest Supported 15m(Customizable) |

| Operation Mode | Continuous / Modulation |

| Range of Welding Speed | 0~120mm/s |

| Cooling Water Machine | Industrial Constant Temperature Dual Temperature Dual Control |

| Operating Ambient Temperature Range | 15~35℃ |

| Working Environment Humidity Range | <70% no condensation |

| Recommendations for Welding Thickness | 0.5-3mm |

| Requirements for Welds | <0.3mm |

| Working Voltage | 220V |

| Size of Machine | 35*28*18(inch) |

| Weight of Machine | 150KG |

Equipment List

| NO. | Main Components | Specification | Logo | Quantity | Remarks |

| 1 | Laser Source | Herolaser | 1 | ||

| 2 | Cooling System | Herolaser | 1 | ||

| 3 | Touch Screen | 7inch | Herolaser | 1 | |

| 4 | Control System | Herolaser | 1 | ||

| 5 | Welded Head | Herolaser | 1 | ||

| 6 | Cabinet | Herolaser | 1 | ||

| 7 | Copper Nozzle | Herolaser | 5 | ||

| 8 | Protective Lens | Herolaser | 5 | ||

| 9 | Wire feeder | Herolaser | 1 |

Consumables and vulnerable accessories

| NO. | Item | Logo | Place of Origin |

| 1 | Copper Nozzle | Herolaser | Heyuan, Guangdong |

| 2 | Protective Lens | Herolaser | Heyuan, Guangdong |

| 3 | Focusing Lens | Herolaser | Heyuan, Guangdong |

| 4 | Collimating Lens | Herolaser | Heyuan, Guangdong |

Laser welding power analysis

|

Laser power |

1000W |

1500W |

2000W |

3000W |

4000W |

6000W |

8000W |

10000W |

12000W |

|

| Material | thickness | |||||||||

|

Stainless steel |

1 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||

|

4 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

5 |

√ |

√ |

√ |

√ |

√ |

√ |

||||

|

6 |

√ |

√ |

√ |

√ |

√ |

√ |

||||

|

8 |

√ |

√ |

√ |

√ |

||||||

|

10 |

√ |

√ |

√ |

|||||||

|

12 |

√ |

√ |

||||||||

|

15 |

√ |

|||||||||

|

20 |

||||||||||

|

25 |

||||||||||

|

30 |

||||||||||

|

40 |

||||||||||

|

Carbon steel |

1 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||

|

3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

4 |

√ |

√ |

√ |

√ |

√ |

√ |

||||

|

5 |

√ |

√ |

√ |

√ |

√ |

|||||

|

6 |

√ |

√ |

√ |

√ |

||||||

|

8 |

√ |

√ |

√ |

√ |

||||||

|

10 |

√ |

√ |

√ |

|||||||

|

12 |

√ |

√ |

√ |

|||||||

|

15 |

√ |

√ |

||||||||

|

20 |

√ |

|||||||||

|

25 |

||||||||||

|

30 |

||||||||||

|

40 |

||||||||||

|

Aluminum |

1 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||

|

3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

4 |

√ |

√ |

√ |

√ |

√ |

√ |

||||

|

5 |

√ |

√ |

√ |

√ |

√ |

|||||

|

6 |

√ |

√ |

√ |

√ |

||||||

|

8 |

√ |

√ |

||||||||

|

10 |

√ |

|||||||||

|

12 |

||||||||||

|

15 |

||||||||||

|

20 |

||||||||||

|

25 |

||||||||||

|

30 |

||||||||||

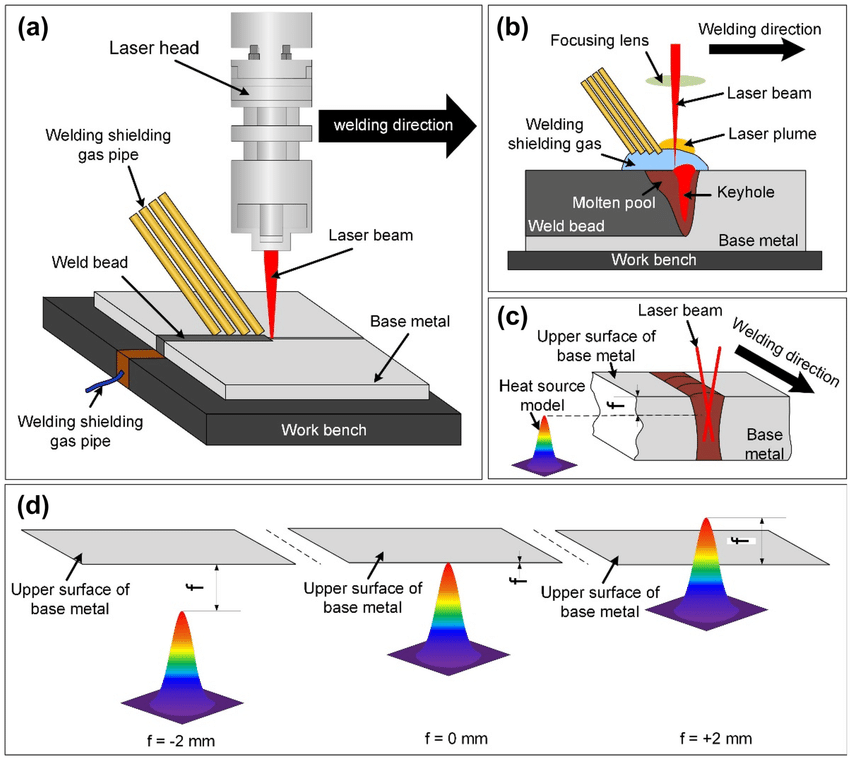

The schematic diagram of the laser welding process:

Different types of laser welding:

|

Laser type |

Wavelength |

Output mode |

Application |

| CW fiber laser | 1070nm | Continuous | Intermittent/continuous welding of the same metal Modulated pulse spot welding |

| YAG laser | 1064nm | Pulse | Spot welding/weld seam applications of the same metal |

| QCW fiber laser | 1070nm | Pulse/continuous | Metal Spot Welding / Continuous Seal Welding |

| Semiconductor laser | 808nm,915nm,980nm | Pulse/continuous | Plastic Welding/Laser Soldering |

HEROLASER Intelligent Laser Processing Equipment Product Catalog

For bulk purchases or customized products, please contact online customer service, or leave a message.

You can also send email to sales@herolaser.net.