Plastic Laser Welding Machine

Product Introduction

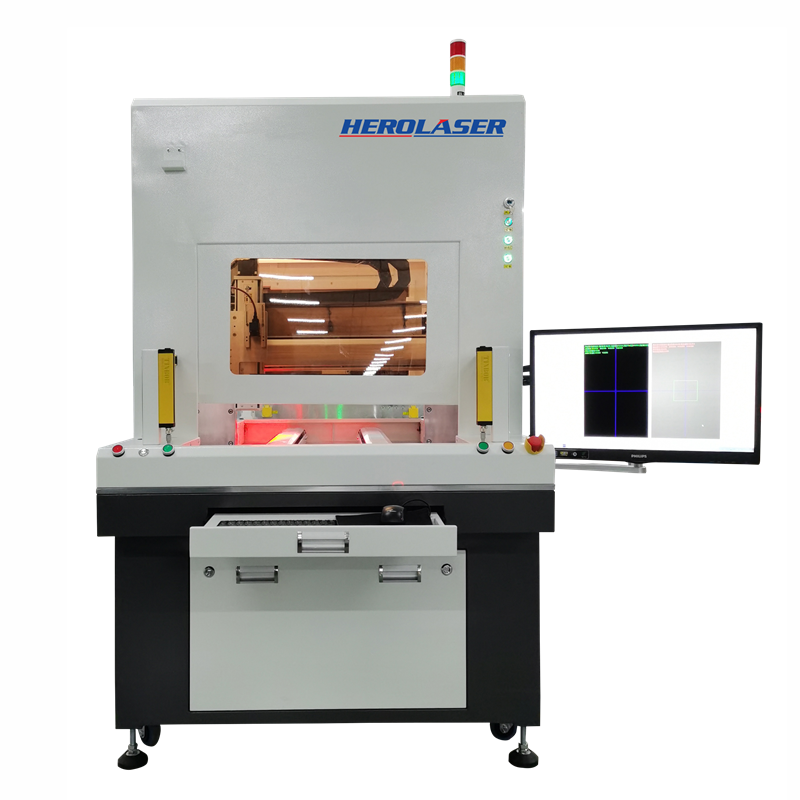

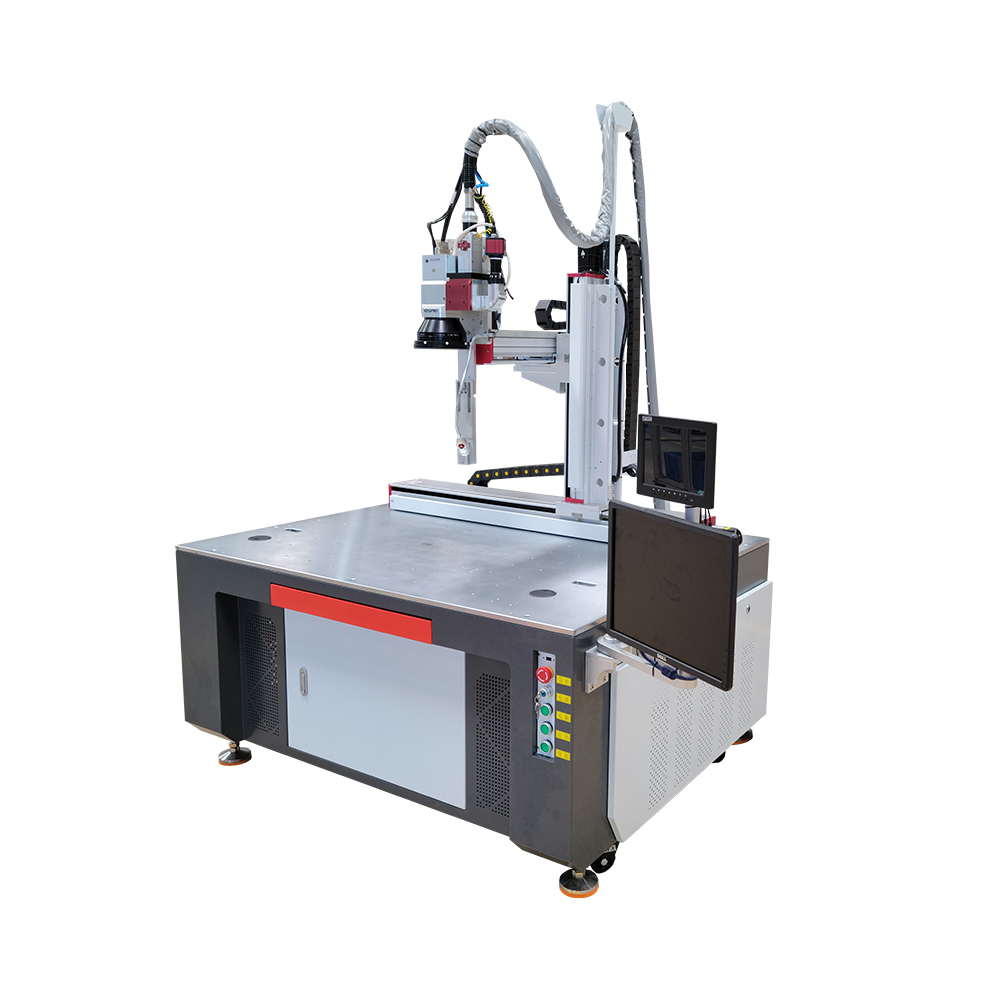

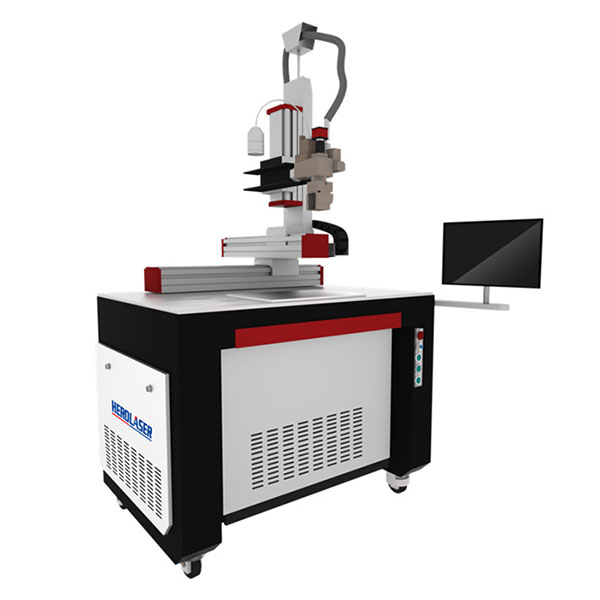

Plastic laser welding machine consists of semiconductor laser, special welding heads and software and 3-axis linear modules, which has radiation-proof closures and integrated design of machine, electricity, water and gas in line with international standards. The machine is capable of continuous track teaching and remote control.

Core Features

1. Real-time quality control via CCD monitoring system and temperature probe.

2. Showing narrow welding seam and elegant appearance in the welding area

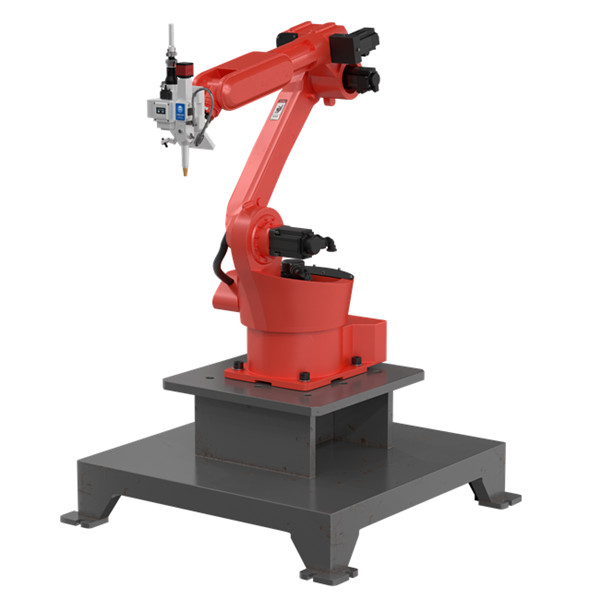

3. Capable of welding products with complex shapes, and can theoretically weld workpieces of any size;

4. Low demand for laser power;

5. No resin degradation and almost no debris during the welding process, and it can be used directly after welding

6. High processing efficiency.

Technical Parameter

|

Technical Parameter |

||

|

No. |

Item |

Parameter |

|

1 |

Laser power | 100W |

|

2 |

Laser wavelength | 915nm |

|

3 |

Working mode | Continuous/adjustable |

|

4 |

Working surface range | X axis: 300mm; Y axis: 200mm; Z axis: 100mm; (can be customized according to customer needs) |

|

5 |

Positioning accuracy | X/Y/Z aies:≦0.05mm |

|

6 |

Working speed | X/Y/Z aies:100mm/s |

|

7 |

Welding line width | 0.5-3.0mm |

|

8 |

Software function | Multi-axis linkage laser welding software |

|

9 |

Cooling method | Air cooling |

|

10 |

Power supply | AC 220V±10% ,50/60Hz |

|

11 |

Power consumption | 1500W |

|

12 |

Working environment | Temperature: 10~35℃; Humidity≤85% |

|

Suitable for materials |

| Suitable for ABS, PP, PE, PA, PC, PS, PVC, PBT, POM, PET, PMMA and other thermoplastic materials and various modified engineering plastics |

Sample Display