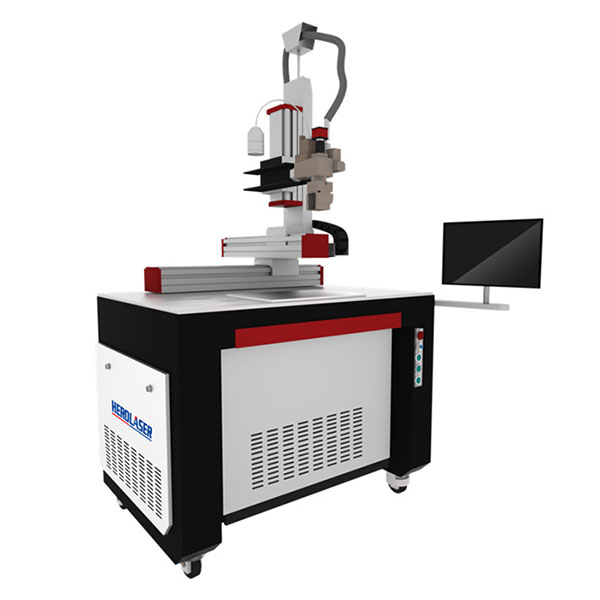

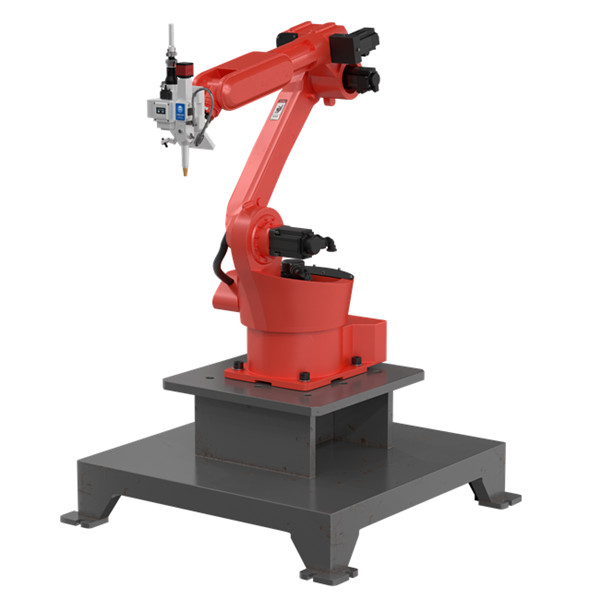

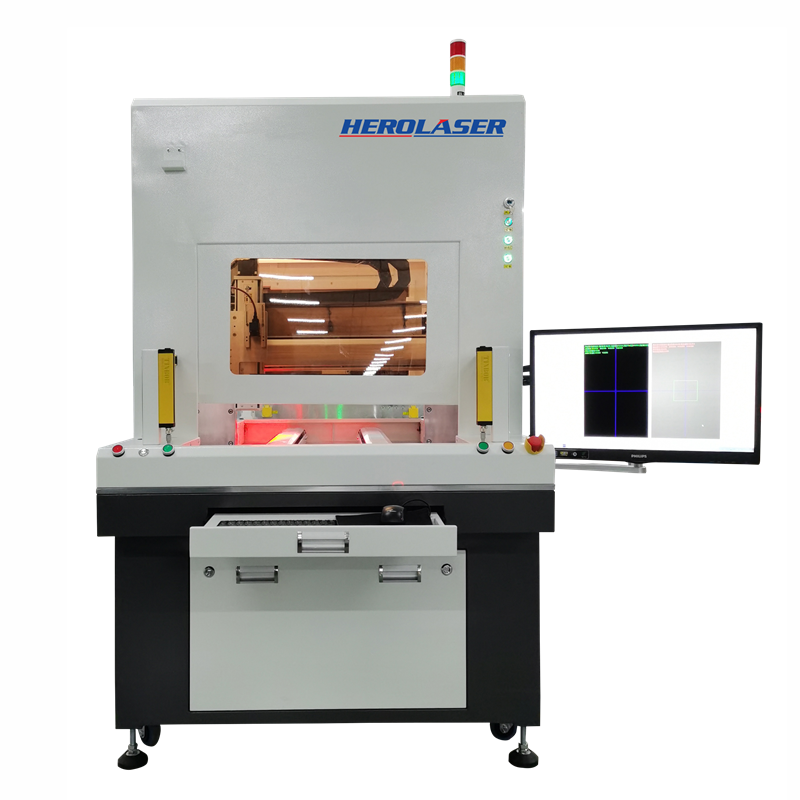

3/4/6 Axis otomatiki Laser Welding Machine

Product Sumo

Gamba laser otomatiki laser welding muchina unogona kuona kukwenenzverwa kwesimbi zvidimbu zvesimbi mumitsara yakatwasuka, madenderedzwa uye mamwe anopokana trajectories, senge dzimba dzenhare, mbozha bhatiri, masensa, zvekurapa uye mamwe maindasitiri.Laser welding machines inoshandisa high-energy pulsed lasers kupinza zvinhu, laser pulses 'high simba uye high density inogona kuita welding kupfava, weld hupamhi idiki uye nzvimbo inobatwa nekupisa idiki, uye inogona kupedzisa iyo chaiyo welding isingagone. kuwanikwa nehunyanzvi hwechinyakare.Laser otomatiki welding muchina akatevedzana welding muchina ndeye laser welding muchina wakagadzirwa uye unogadzirwa neGerman welding muchina tekinoroji.

Kushanda kwewelding kwakakwira, mhedzisiro yacho yakanaka, uye kushanda kuri nyore uye kuri nyore.Inokodzera kusungirirwa kwemitsara yakatwasuka, ma arcs uye arbitral trajectories emhando dzakasiyana siyana.Inoshanda kune ese marudzi emidziyo yesimbi: aruminiyamu, simbi isina tsvina, goridhe, sirivheri, alloy, simbi, diamond yakaenzana zvinhu welding kana dissimilar material welding;inoshanda siyana: nharembozha mabhatiri, zvishongo, zvemagetsi zvinoriumba, masensa, wachi, chaiyo muchina, kutaurirana, mabasa emaoko uye mamwe maindasitiri.

Gamba laser otomatiki laser welding muchina unotora dhizaini dhizaini, yakapusa uye yakapusa kuisirwa uye kushanda, inotora yakazvigadzirira kutonhora sisitimu, haidi chero shongwe yemvura yekunze yekutonhodza mvura, iyo yakanyanya frequency inogona kusvika 100HZ, mutsara kumhanya unogona kusvika 8mm / s. , iyo inovandudza zvakanyanya kushandiswa kwekugadzirisa uye kusungirirwa kwehutano.Inogona zvakare kuve yakashongedzerwa ine mana-dimensional bhora screw tafura, uchishandisa kunze kwenyika servo control system, kusanganisira tafura inotenderera, inogona kubatanidza cylindrical zvinhu uye zvimwe zvinhu zvemaumbirwo akasiyana, ine huwandu hwakasiyana hwekushandisa, yakanyanya kurongeka uye kukurumidza kukurumidza. .Iyo yazvino waveform inogona kugadziridzwa zvisina tsarukano, iyo inogona kuiswa kune akasiyana zvinhu uye alloys.

Technical Parameters

| Zita rechikamu chikuru | Parameter |

| X axis inoshanda sitiroko | 500mm |

| Y axis inoshanda sitiroko | 300mm |

| Z axis inoshanda sitiroko | 300mm |

| Dimensions | 1500×1400×1900mm |

| Machine uremu | 280kg |

| Module kushanda kumhanya | Y axis:10m/min |

| X axis:10m/min | |

| Z axis:5m/min | |

| yakadzokororwa nzvimbo yakarurama | ± 0.02mm |

| Tafura inotenderera | Denderedzwa kumhanya kwechokwadi ≤0.05mm |

| kudiwa kwemagetsi | 220V/380V |

| Avhareji mutoro simba | 7.5KW |

Configuration Parameter

| S/N | Name | Specifications& Models | QTY | Brand | Remark |

| 01 | Fixture mounting plate | 350mm × 450mm | 1 | Gamba Laser Tsika | |

| 02 | Laser | Zvinoenderana nemuenzaniso welding zvinodiwa | 1 | MAX kana IPG | |

| 03 | Motor | servo mota | 3 | Huichuan | |

| 04 | Computer | PC/Industrial Computer | 1 | Advantech | |

| 05 | Chiller | Maererano nelaser simba | 1 | S & A | |

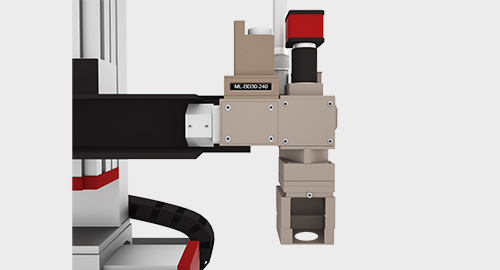

| 06 | Welding musoro | Zvinoenderana nemuenzaniso welding zvinodiwa | 1 | Hero Laser | |

| 07 | CCD Visual yekutarisa system | kamera | 1 | Microsan | |

| light source | Basler/LeTV Chiedza Chitubu | ||||

| 08 | Z axis module | 300mm sitiroko | 1 | Gamba Laser Tsika | X, Y axis screw lead 10mm, Z axis screw lead 5mm;screw kururama: C7 |

| 09 | X axis module | 500mm sitiroko | 1 | Gamba Laser Tsika | |

| 10 | Y axis module | 300mm sitiroko | 1 | Gamba Laser Tsika | |

| 11 | Tafura inotenderera | Three-shaya rotary chuck | 1 | Gamba Laser Tsika | |

| 12 | Lower cabinet | Sheet metal welding, pendi kubika | 1 | Gamba Laser Tsika |

Core Features

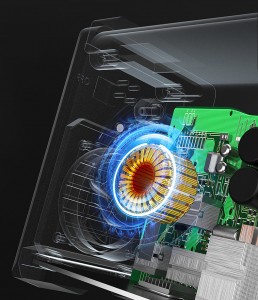

1. Yakanakisa danda remhando: Adopt Germany IPG, uye imwe yakavimbika advanced faibha laser sosi, danda remhando iri nani pane yechinyakare solid-state laser, yakanangwa nzvimbo dhayamita isingasviki 20um, divergence angle ndeye 1/4 ye diode-pumped laser.Kunyanya akakodzera kumaka kwakanyatso uye kwakanakisa.

2. Mutengo wakaderera: Iyo yepamusoro yemagetsi / optical kutendeuka mwero inosvika makumi matatu muzana, iyo simba rese rekushandisa iri pasi pe500W, iyi 1/10 yemwenje-pumped solid-state laser yekumaka muchina, chengetedza yakawanda yesimba mutengo.

3. Maintenance-isina: laser sosi hapana chikonzero chekugadzirisa, zvakare hapana chikonzero chekugadzirisa kana kuchenesa lens.

4. Hupenyu hwesevhisi yenguva refu yelaser sosi: fiber laser yekumaka muchina inoshandisa laser diode sepombi sosi, avhareji yenguva sevhisi inogona kusvika ku100,000 maawa.

5. Yakakwira yekumaka kumhanya: Iyo yekumaka yekumhanyisa inopfuura 3 nguva yekutanga neyechipiri chizvarwa chelaser mamaki.

High simba pulsed laser welding

Yakagadzirwa uye yakagadzirwa kubva kuGerman welding muchina tekinoroji

Maintenance pasi / Yakanyanya kurongeka / Flexible zvakakwana

Self equipped cooling system inogamuchirwa

Hapana shongwe yemvura yekunze inodiwa pakutonhodza

Application Scenarios

Digital nharembozha bhatiri indasitiri

Mobile nhare shell industry

Indasitiri yezvekufambisa

Medical equipment industry

Uye mamwe maindasitiri ari kushaiwa

Vhidhiyo uye Nhau dzechigadzirwa ichi

Otomatiki Laser Welding Machine

musi waKubvumbi 21,2022

Otomatiki Laser Welding Machine

musi waKubvumbi 21,2022

Laser Welding Machine

musi waKubvumbi 21,2022

kumbira mutengo wakanakisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu