Inotakurika Handheld Laser Welding Machine

Product Sumo

Handheld laser welding ndeyemunda welaser welding, iyo laser welding seimwe yematatu akanyanya kukosha maapplication mukugadzirisa laser.Kwemakore gumi apfuura, laser yekumaka inotungamira yekutanga kuwedzera, inoita kunge yakakurumbira, uye iyo laser yekucheka inotanga kubva yekutanga YAG, CO2 laser yekucheka yakagadziridzwa kune fiber laser yekucheka, kwavewo kukurudzira kukuru.Laser welding yanga ichivimbisa, asi kudiwa kwemusika hakuna kuwedzera zvakanyanya, kudzamara kuputika kwemotokari nyowani dzesimba mumakore achangopfuura, uye kuwedzera kwebhatiri remagetsi kwakatungamira mukukura kwelaser welding.

Technical Parameters

| Optical performance parameters | |

| Laser Simba | 1500W |

| Output laser wavelength | 1075nm ± 10mm |

| Maximum modulation frequency | 50KHZ |

| Operation Mode | Inoenderera / Modulation / Nguva |

| Simba kugadzikana | <5% |

| Laser mhinduro nguva | <10us |

| Inoratidza laser wavelength | 650nm |

| Kuratidza Chiedza Kugadzirisa Range | <1mW |

| conduction system parameters | |

| Port Type | Otomatiki Wire Kudyisa Welding Musoro |

| Collimating focal kureba | 50mm |

| Kutarisa Kure | 150mm |

| Transmission Length | Standard 5±0.5m, (Sarudzo 10m) |

| Kushanda Ambient Temperature | 10 ~ 50 ℃ |

| Kushanda Ambient Humidity | ≤ 85 dhigirii |

| Kutonhora uye Dziviriro Gasi | Inert Gas |

| Input Voltage | 220 VAC/50Hz/60Hz |

| Machine Power | ≤4.8KW |

Core Features

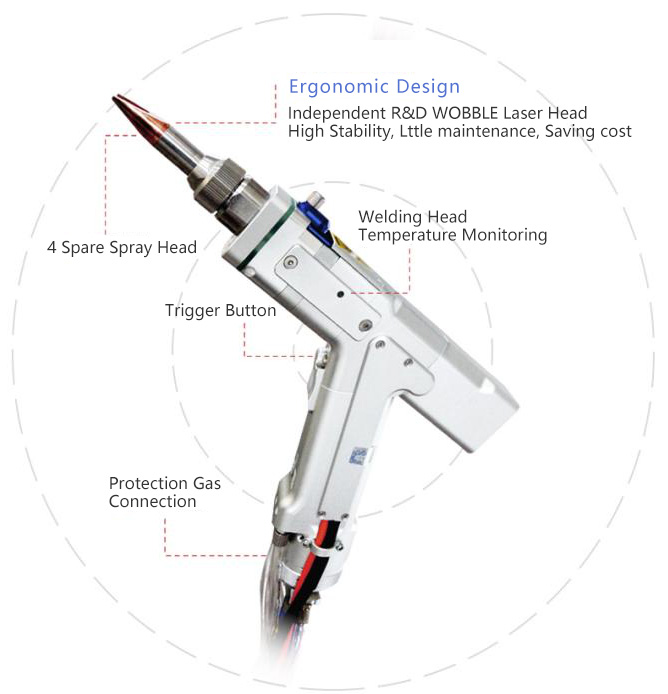

1. WOBBLE handheld laser head, yakareruka uye inochinjika, inogona weld chero chikamu cheworkpiece

2. Yakavakwa-mukati-inopisa mbiri-inodzora maindasitiri chiller

3. Constant temperature regulation and heat dissipation kuti ive nechokwadi chekupisa kwekupisa kwe core optical circuit components.

4. Kushanda kuri nyore, kunogona kushandiswa nyore nyore nekudzidzira nyore

5. Zvigadzirwa zvakanaka zvinogona kusungirirwa imwe inotora pasina tenzi

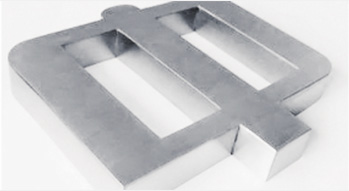

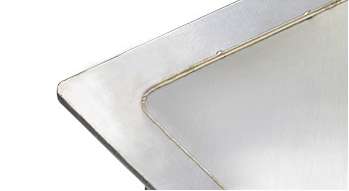

Fillet welding

Lap welding

Tailor welding

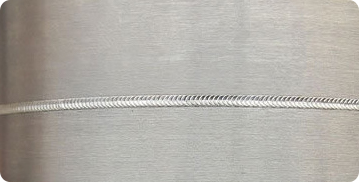

Sona welding

Mhepo-inotonhorera Handheld Fiber Laser Welding Machine

Pazvino kutengeswa kwe1000W uye 1500W air-cooling laser welders.Mukana uri mukubatanidzwa kwemukati, vhoriyamu diki uye uremu 75KG chete, iri nyore pakufambisa uye haidi kutsiva mvura.

1. Flexible uye nyore

2. Utano-kudzivirira uye zvakatipoteredza ushamwari

3. Inodhura-inoshanda

4. Welding yakasimba

5. Welding yakanaka

6. WOBBLE welding teknolojia

Application Scenarios

Muchina uyu wakabatwa neruoko welaser welding wakakodzera simbi yegoridhe, sirivheri, titanium, nickel, tini, mhangura, aluminium uye imwe simbi uye nealloy material, inogona kuwana kucheneswa kwakafanana pakati pesimbi nesimbi dzakasiyana, yakashandiswa zvakanyanya mumidziyo yemuchadenga. , shipbuilding, instrumentation, mechanical uye magetsi zvigadzirwa, motokari uye mamwe maindasitiri.

Vhidhiyo uye Nhau dzechigadzirwa ichi

Handheld Laser Welding Machine

musi waKubvumbi 21,2022

Handheld Laser Welding Machine

musi waKubvumbi 21,2022

Handheld Laser Welding Machine

musi waKubvumbi 21,2022

kumbira mutengo wakanakisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu