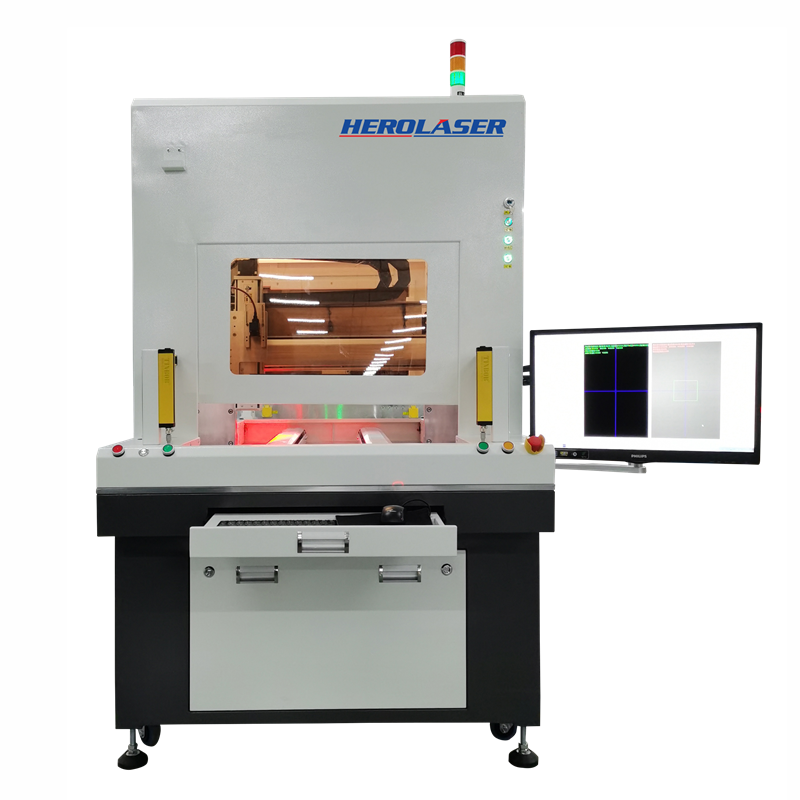

Kaviri chiteshi inogara tembiricha laser solder muchina

Product Sumo

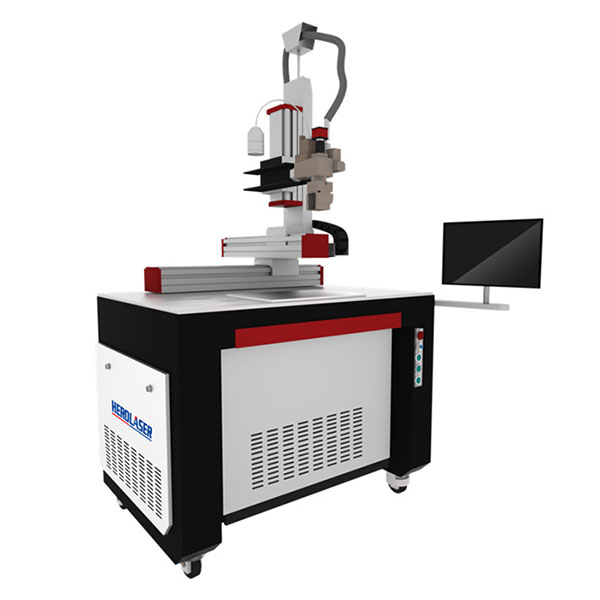

Iyo midziyo ine akawanda ekushanda modhi uye otomatiki waya yekudyisa sisitimu kana otomatiki chaiyo solder paste yekuparadzira mudziyo kuti unyatso solder munguva dzakasiyana.Kune zvimwe zvigadzirwa zvemazvo izvo zvisingakwanise kugadzirisa ne reflow soldering uye wave solder muchina, laser solder muchina ichave yako yakavimbika sarudzo yekutengesa zvigadzirwa zvako uchipihwa hunhu hwekugadzika chimiro, mutengo-kushanda, kugona kwakanyanya kwekutengesa uye nhamba yekudzora tekinoroji.

| Technical Parameter | ||

| Aihwa. | Item | Parameter |

| 1 | Model | ML-WS-XF-ZD2-HW80 |

| 2 | Laser simba | 60W-200W |

| 3 | Laser mhando | semiconductor |

| 4 | Kutarisa kureba | 80/125/160mm(optional) |

| 5 | Temperature control range | 60°C-400°C |

| 6 | Temperature System Kururama | ±( 0.3% kuverenga + 2°C) (ambient tembiricha 23±5°C) |

| 7 | GPS | ICoaxial CCD yekutarisa uye nzvimbo yeCCD inomira |

| 8 | Equipment size | 1100mm*1450mm*1750mm |

| 9 | Welding range | 250mm * 250mm(single working station) |

| 10 | Kudyisa sitiroko | 1000mm |

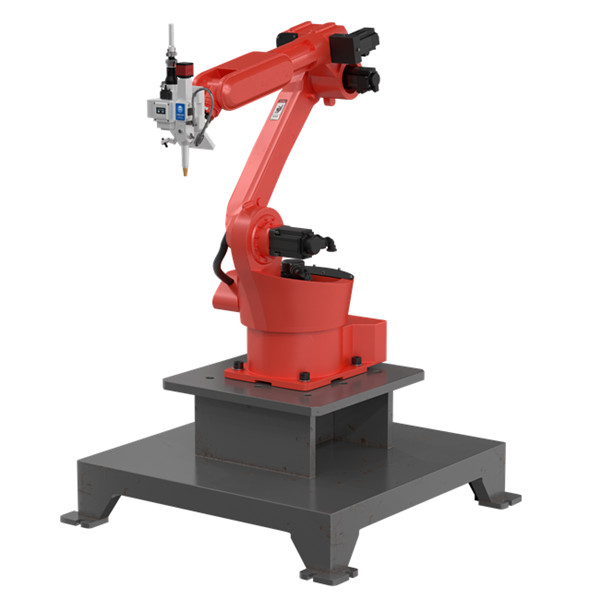

| 11 | Nhamba yematemo ekufambisa | 6 mbezo(X1 Y1 Z1/X2 Y2 Z2) |

| 12 | Kudzokorora | ± 0.02mm |

| 13 | Kubvisa guruva hurongwa | Otomatiki soot yekuchenesa system |

| 14 | Total Weight | 350Kg |

| 15 | Total power | ≤2.5KW |

Core Features

1. Adopt semiconductor laser, kushanda nenzira isiri-contact processing way.

2. Hapana kushandiswa kwesimbi yesimbi, inomhanya mumutengo wakaderera uye nyore kugadzirisa.

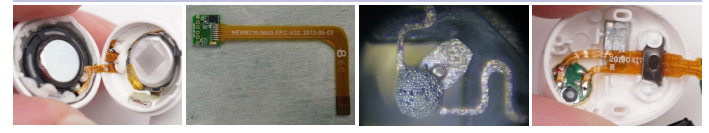

3. Visual positioning solder point kuburikidza neDual vision application uye CCD monitoring system.

4. Laser iri kugadzirisa pasi pekushisa nguva dzose kuburikidza nemukati yakavharwa-loop mhinduro ye-real-time tembiricha yekutarisa.

5. Nzvimbo yewelding inogona kugadziriswa kuti isangane nemhando dzakasiyana dzekutengesa.

6. Isa chiutsi chekuchenesa hurongwa kuti ubvise panguva yekupisa zvisaririra kubva mukutsva.

7. Sarudzo yekuchinja pakati pechiteshi chimwe chete uye Double chiteshi modhi.

Muenzaniso Display

kumbira mutengo wakanakisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu