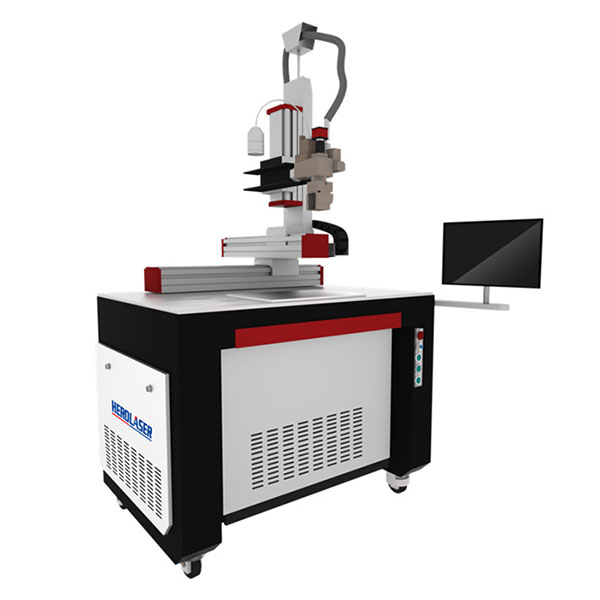

Mold Kugadzirisa YAG Laser Welding Machine

Product Sumo

Herolaser mold kugadzirisa laser welding muchina akateedzera indasitiri ye mold inoshanda, iyi modhi yakatsaurirwa kutsiva yechinyakare argon welder yekugadzirisa chaiyo mold.Zvese zvakakosha zvemuchina uyu zvinotengeswa kunze kwenyika.Iyo software yekushandisa interface inoshandisa yakakura LCD skrini uye inoratidza mitauro yakawanda, iri nyore uye iri nyore kushandisa kune anoshanda.Multiple presetting inoshanda modhi, zvakare inogona kurongeka nevashandisi, zvachose ndangariro basa, inoshanda kune dzakasiyana siyana zvinhu.

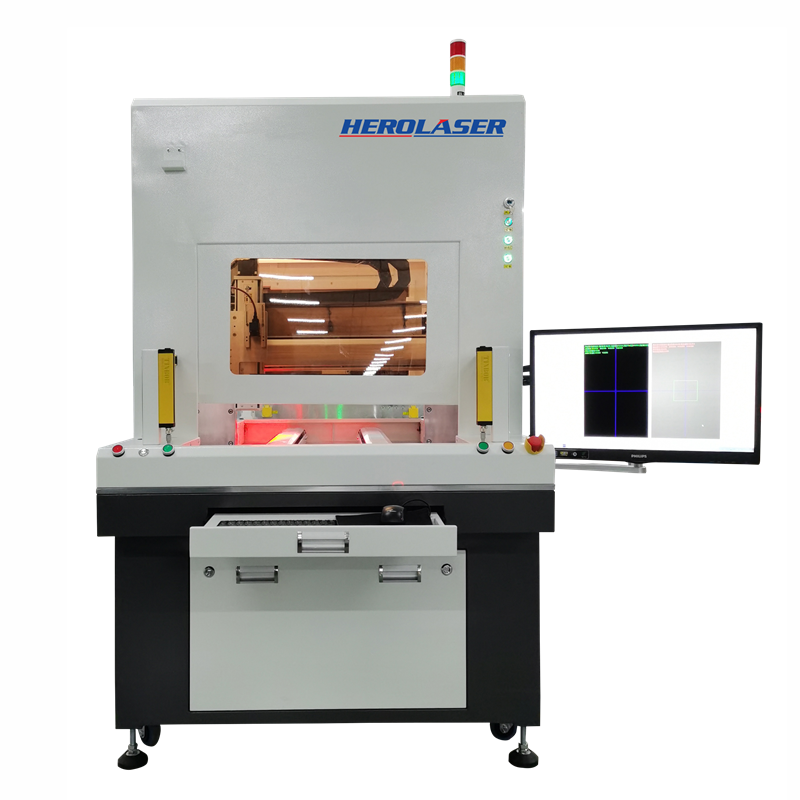

Yakashongedzerwa neyakakosha maikorosikopu yekutarisa sisitimu, magnification 10x;Iko kune yakakwirira-yekumhanya yemagetsi sefa yekudzivirira yekudzivirira maziso emushandisi kubva mukukuvadzwa nelaser, kudzoreredza kuneta kweziso remushandisi uye kugadzirisa kushanda nesimba.

Iyo synchronous argon kuchengetedza sisitimu ine yemukati microcomputer control inogona kudzivirira weld kubva kune oxidized uye kuita welding yakasimba uye yakanaka;Argon inogona kuponeswa kusvika pamwero mukuru nekutora synchronous control ine laser emission

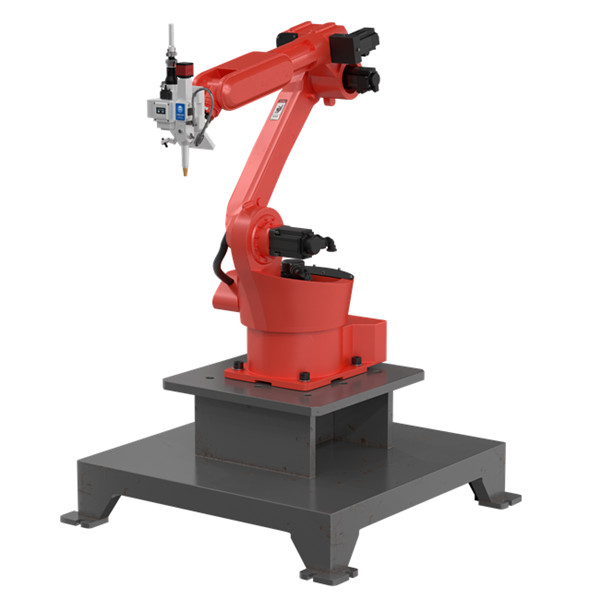

Iyo tangi yemvura yerobhoti laser welding muchina unogona kupisa uye kutonhora muchina, uye kutarisa tembiricha yemvura munguva chaiyo.Iyo ine nguva dzose tembiricha / kutenderera modhi

Iyo laser host cabinet inogona kunyatsoona chimiro chechigadzirwa uye welding mhedzisiro zvinoenderana neyakatsvuka mwenje chiratidzo

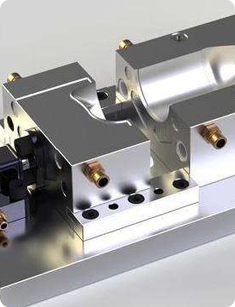

Iyo huru yemuchina workbench uye nzvimbo inoiswa welding workpiece iri nyore kuti laser weld workpiece.

Technical Parameters

| MODEL: | ML-WY-BP-DB-W200 | ML-WY-BP-DB-W400 |

| 3-axis sitiroko yebhenji rebasa | X=300mm,Y=200mm(X,Y inogona kugadziriswa nemaoko uye z-axis inogona kusimudzwa) | |

| Kutakura bhenji rebasa | ≤200KG | |

| Magetsi | 220V±10%/50Hz Kana 380V±10%/50Hz | |

| Laser parameters | ||

| Laser mhando | Nd:YAG pulse | |

| Kugadzirisa huwandu hwenzvimbo yechiedza | 0.1~0.3mm | |

| Saizi yenzvimbo yechiedza | 0.2-3.0mm | |

| Laser wavelength | 1064nm | |

| Pulse width | 0.5~25ms | |

| Maximum laser simba | 200W | 400W |

| Pulse frequency | ≤50Hz | |

| Laser inobuda inotarisa kureba | 80mm/100mm/120mm(kusarudza) | |

| Laser kutonhora | Kutonhora kwemvura | |

| Kucherechedza system | Maikorosikopu (360° inochinjika) | |

| Dziviriro gasi | Mutsetse mumwe (xenon) | |

| Solder parameter | ||

| Welding waya dhayamita | 0.1mm~0.8mm | |

Core Features

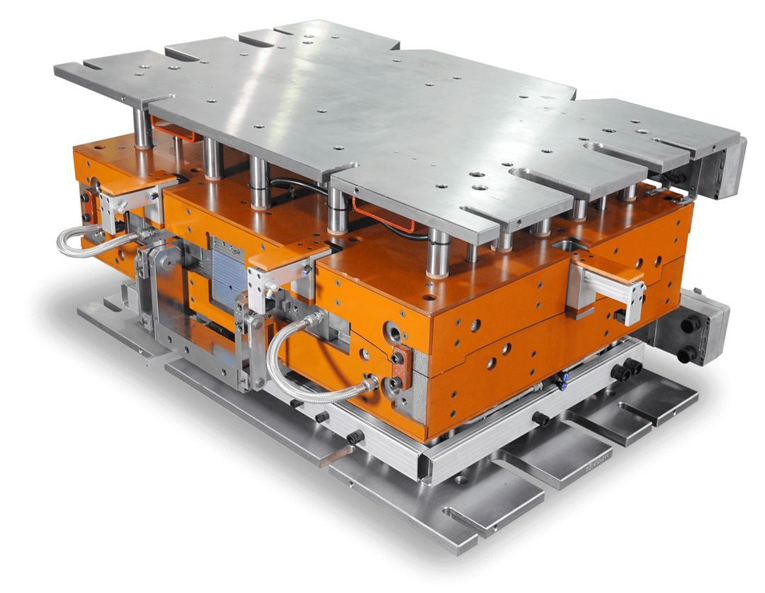

1. Kupisa kwakakanganisika nzvimbo idiki, kudiki deformation kune chaiyo molds.

2. Welding kudzika yakakura, welding zvakasimba.Yakakwana fusion, hapana kugadzirisa matanho.Hapana dimple phenomena pakusanganisa chinzvimbo chezviratidziro zvikamu uye bulge chikamu cheyakanyungudutswa dziva rinonyungudika.

3. Low oxidation rate, ruvara rwezvikamu zvekugadzirisa hazvina kusimba.

4. Hapana stomata kana gomba rejecha rakanyangarika mushure mekucheka.

5. Zvikamu zvekushongedza zvinogona kugadziriswa, kunyanya zvakakodzera kupukuta zvinodiwa zvekugadzirisa mold.

6. Zvikamu zvekugadzirisa zvinogona kusvika ku50 kusvika ku60 Rockwell kuoma.

Hapana deformation ye welding inofa

Kupisa kwakakanganiswa nzvimbo idiki, iyo isingazotungamira kune deformation yeiyo chaiyo kufa, uye hapana kuora mwoyo pamubatanidzwa pakati pechikamu che convex chechinhu chakanyungudutswa mudziva rakanyungudutswa uye matrix.

● The oxidation mwero yakaderera uye workpiece haizoshanduki ruvara pashure welding

● Nzvimbo yekudziya idiki, uye zvikamu zvemichina hazvizokanganisi

● Pachave pasina pores kana trachoma mushure mekucheka

● Mushure mekunama, inogona kuiswa pasina kukanganisa maitiro

Application Scenarios

Mold industry

Metalworking

Kugadzira michina

Vhidhiyo uye Nhau dzechigadzirwa ichi

Laser Welding Machine

musi waKubvumbi 21,2022

Laser Welding Machine

musi waKubvumbi 21,2022

Laser Welding Machine

musi waKubvumbi 21,2022

kumbira mutengo wakanakisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu