Zvakanakira handheld laser welding muchina mukicheni uye yekugezera indasitiri

Muhupenyu hwedu hwezuva nezuva, hatigone kurarama tisina kicheni neimba yekugezera.Kicheni yemazuva ano uye yekugezera inosanganisira sirin'i, kicheni uye yekugezera fenicha, yakakosha kabati, yekugezera kabati, yakangwara midziyo, yekugezera hita, mhepo inofefetera, yekuvhenekesa system, chitofu chakabatanidzwa uye zvimwe kicheni uye yekugezera zvine chekuita nemidziyo.Iyo yechinyakare welding nzira yekicheni uye yekugezera indasitiri yemidziyo inonyanya kunyorerwa argon arc welding.Iyi nzira yewelding ine zvakawanda zvisingabatsiri, sekutora kwakaoma kwevashandi, kwakaoma maneja manejimendi, kudhura kwevashandi, kuderera kwegoho, kuchengetedzeka kwakaderera, kuderera kweaesthetics, dhigirii rakaderera re automation uye zvichingodaro.Laser welding inogona kunyatsogadzirisa matambudziko aya.

Kuipa kwemanyorero welding mukicheni uye yekugezera appliance industry

1. Mutengo wepamusoro wevashandi: mubairo wevanopisa mukicheni, imba yekugezera uye indasitiri yemidziyo yemumba inodarika 10000 yuan, uye hapana mashoma mawelder mufekitori imwe neimwe yakura.Mukufamba kwenguva, mutengo wevashandi imari huru yemabhizinesi.

2. Low welding performance: nhamba yevelders mufekitari ishoma, uye nhamba ye welders welded zuva rega rega ishoma, izvo zvinotungamirira kuhuwandu hushoma hwezvigadzirwa zvinogadzirwa nefekitari zuva rega rega.Mukufamba kwenguva, inotungamirira kune yakaderera kushanda uye kusakwanisa kuenderana nehuwandu hwekugadzira.

3. Kuchengetedzwa kwakaderera: manual welding inonyanya kushandiswa nevanhu, iyo inobudisa kupisa kwakanyanya panguva yekuputika.Kushanda kusina kunaka kunokuvadza maoko nemaziso emushandisi.

4. Low Aesthetics: manual welding inonyanya kushandiswa nevelders.Akasiyana-siyana welders ane akasiyana welding nzira, izvo zvinogona kutungamira kune mutsauko mune zvigadzirwa zvakasungwa.Mamwe mawelders ane hunyanzvi, uye zvigadzirwa zvakakandwa zvichave zvakanakisa.Mamwe mawelders haana kujaira, uye zvigadzirwa zvakashongedzwa zvinogona kunge zvine maburrs mazhinji nemakomba, izvo zvinokanganisa aesthetics yezvigadzirwa zvakazara.

5. Yakaderera dhigirii ye otomatiki: kicheni uye yekugezera indasitiri yemidziyo inotongwa nemaoko welding, uye maitiro evashandi haadzoreki, zvichikonzera kutenderera kwekugadzirwa kwechigadzirwa chimwe nechimwe hachidzoreki zvachose.Yakaderera degree ye automation

Zvakanakira zve handheld laser welding mukicheni uye yekugezera appliance indasitiri

1. Deredza mutengo wakazara: mutengo wekutanga wekutenga wehandheld laser welding muchina wakakwira.Hupenyu hwesevhisi yemuchina wekubata laser welding muchina anopfuura makore gumi.Mamwe mabhizinesi akadzora mutengo mukati mehafu yegore mushure mekutenga laser welding muchina, uye ari padanho remubhadharo wakazara kweanopfuura makore mapfumbamwe.Kunyangwe iyo laser welding muchina uchinge wakuvadzwa panguva yekushandiswa, unozounza mari yekugadzirisa, iyo inogona kutarisirwa.

2. Yakagadzirisa dambudziko rekuchengetedza: ruoko rwakabata laser welding machine is machine welding pasina manual welding, iyo inovandudza kuchengetedzwa kwevashandi.

3.Kugadzirisa dambudziko reAesthetics: handheld laser welding machine inoshanda zvakakwana maererano nemaitiro ekugadzirira, uye zvigadzirwa zvakashongedzwa zvine high aesthetics uye yakakwirira kuenderana.

4. Kuvandudzwa kwekugadzirwa kwechigadzirwa: kushandiswa kwemaoko laser welding machine inoshanda maererano ne preset process, iyo isingakanganisi nekunze kwezvinhu zvakadai sevashandi.Mune mamwe mamiriro ezvinhu, hapana dambudziko usiku.

5. Kuvandudza dhigirii ye automation: handheld laser welding machine inoshanda maererano ne preset process, iyo inovandudza zvikuru dhigirii ye automation.

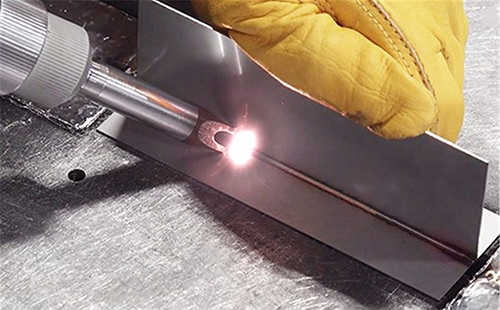

Kubuda kwehandheld laser welding muchina unongogadzira izvo zvinokanganisa zvechinyakare welding.Laser inovandudzwa zvakare pahwaro hwelaser welding.Iyo handheld laser welding muchina inotora yakasanganiswa dhizaini ine yakavakirwa-mukati integrated control system, laser system, inotonhorera sisitimu uye mamwe maitiro;Pfuti inobatwa nemaoko inoshandiswa kutsiva iyo yakambogadziriswa nzira yekuona, uye hapana chikonzero chekumisikidza midziyo yekuisa tafura yewelding, iyo inotora nzvimbo diki uye inogona kuona welding yekunze;Musoro unobatwa nemaoko welding unoshanduka uye wakanakira.Zvinoenderana nezvinodiwa nemusika, akasiyana akakodzera welding nozzles akagadzirwa kuti atsigire nzvimbo welding, overlap welding, fillet welding uye dzimwe nzira dzewelding.Yakakodzera kukurumidza kuputika kwekabhoni simbi, simbi isina tsvina, aruminiyamu alloy, titanium alloy, galvanized plate, aluminium zinc plate, ndarira, tsvuku mhangura nedzimwe simbi.

Nguva yekutumira: Kubvumbi-12-2022