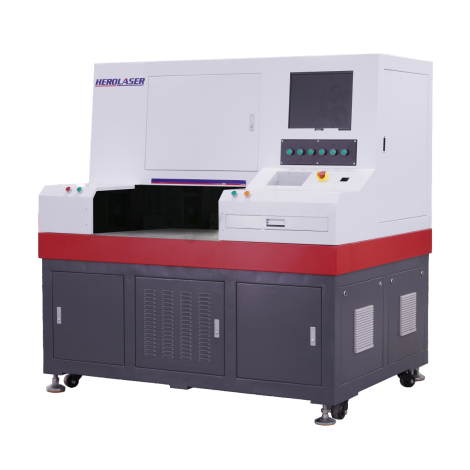

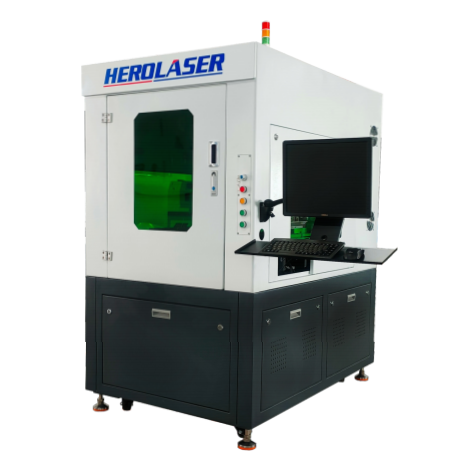

Inotakurika Fiber Laser Kumaka Machine

Product Sumo

Yakabatanidzwa ne mini yekumaka sisitimu, inotakurika fiber laser yekumaka muchina inogadzirwa kubva kune yakajairwa fiber laser yakagamuchirwa zvakanyanya pamusoro pemusika wepamba uye wepasirese.Muchina wekumaka unoita mabasa ayo umo fiber laser iri kuburitsa uye nekumhanyisa scanning kuburikidza negalvanometer system.Nenzira iyi inokonzera kushanda kwayo kukuru pane electro-optical conversion.Icho chokwadi chekuti kuigadzira nemhepo inotonhorera uye compact muhukuru inogonesa fiber laser kushanda nekugadzikana uye yemhando yebeam's dudziro inowanikwa pane ese simbi uye zvimwe zvisiri zvesimbi zvinhu etc.

Technical Parameters

| Model | ML- MF- TY- BX- HWXX |

| Laser Simba | 20W/30W/50W |

| Laser wavelength | 1064nm |

| Kudzokorora Frequency | 20-200KHZ |

| Beam Quality | M²<1.2 |

| Kumaka Range | 70mm x 70mm ~ 300mm x 300mm(Sarudzo) |

| Kumaka Speed | ≤7000mm/s |

| Min.Character | 0.15mm |

| Kudzokorora Kwakarurama | ±0.002 |

| Magetsi | 220V / 50-60Hz |

| Shandisa Simba | 800W |

| Cooling Way | Yakavakwa-mukati kutonhora kwemhepo |

Core Features

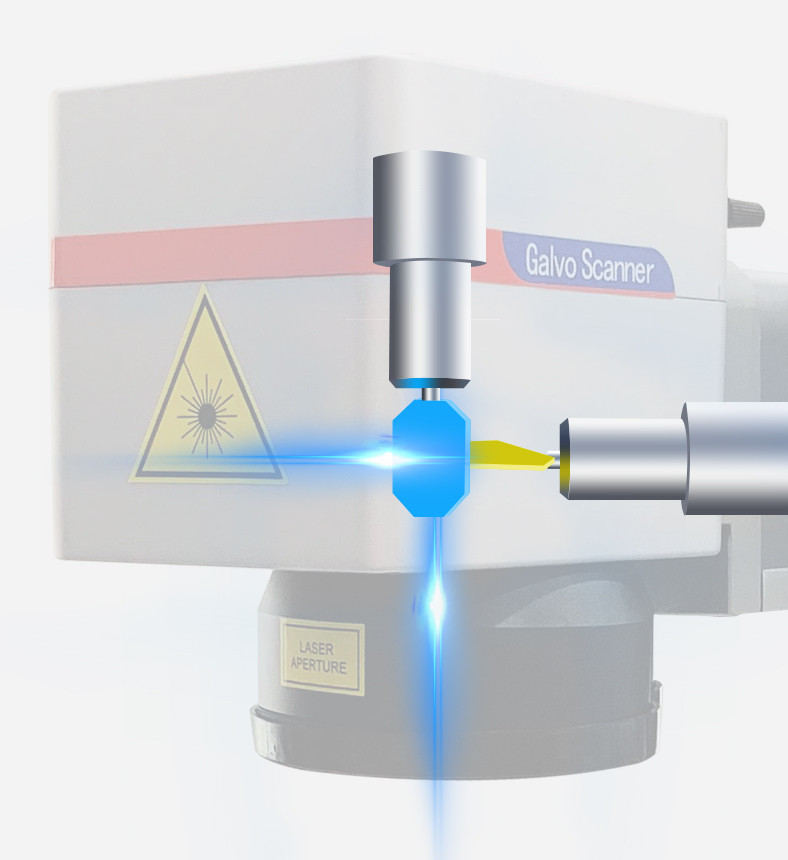

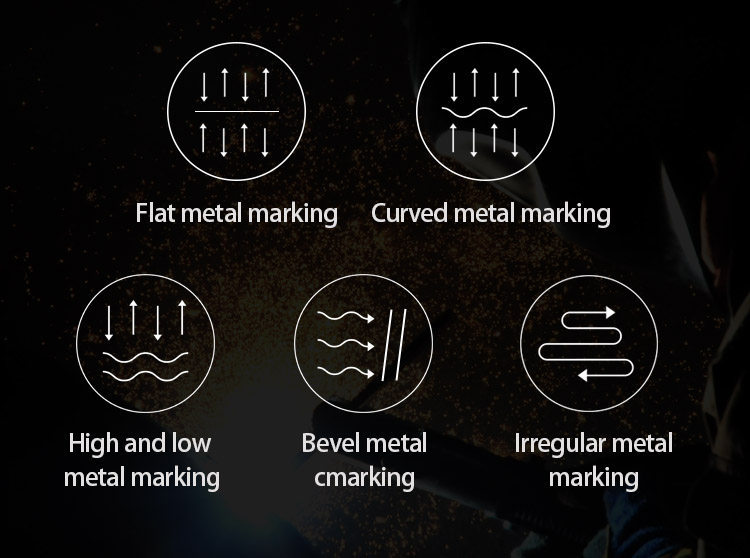

Iyo optical fiber laser inoshandiswa kuburitsa iyo laser, uye ipapo iyo yekumaka basa inowanikwa kuburikidza neyakakura-kumhanyisa scanning galvanometer system, kuitira kuti iyo optical fiber laser yekumaka chinzvimbo chakakwirira uye yekumaka nzvimbo haina kuremara.

1. Inogona kugadzirisa zvakasiyana-siyana zvesimbi uye zvisiri zvesimbi.Kunyanya, zvakanyanya kubatsira kumaka zvinhu zvine kuomarara kwepamusoro, kunyungudika kwakanyanya uye brittleness.

2.Iyo isiri-contact processing, hapana kukuvadza kune zvigadzirwa, hapana kupfeka kwechishandiso uye kunaka kwekumaka kunaka.

3. Laser beam yakatetepa, iyo inoshandiswa inoshandiswa ishoma, uye kupisa kwekugadzirisa kukanganiswa nzvimbo idiki.

4. Kushanda kwepamusoro-soro, kutonga kwekombiyuta uye automation.

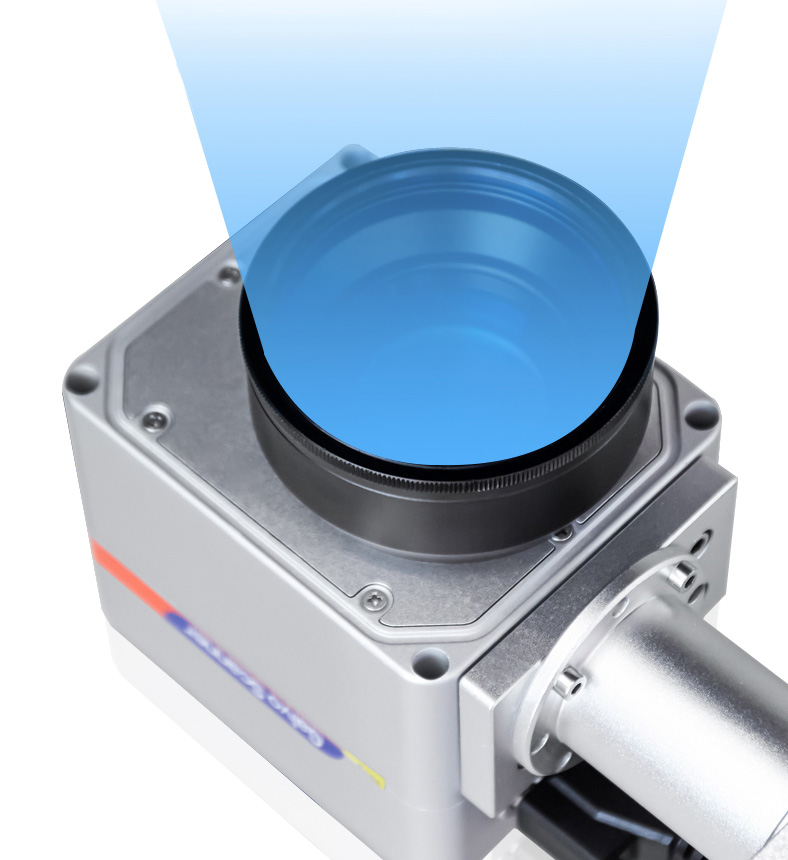

HD sparent marking galvanometer

Yakanyanya kujeka, chenesa lenzi pasina tsvina, wedzera fomati uye ona mhando.Lens yakanaka chete inogona kutara chigadzirwa chakanaka

High electro-optic kutendeuka kushanda zvakanaka

Iyo laser yekumaka muchina sisitimu yakagadziridzwa nekushandisa fiber lasers kumba nekune dzimwe nyika ine yakanaka kubuda danda mhando, kuvimbika kwepamusoro uye electro-optic shanduko inoshanda.

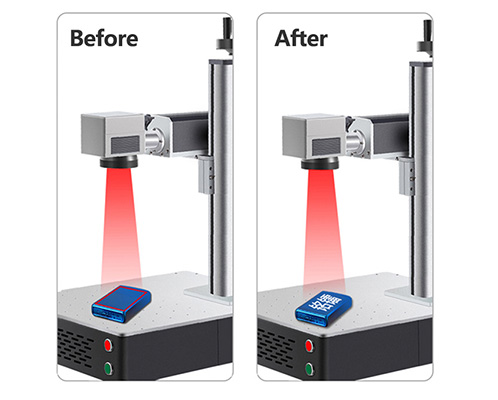

1. Surface mark: Yakanakira pakumaka pamajasi pasina kupinda mukati, senge chrome, nickel, goridhe, uye sirivheri nezvimwe.

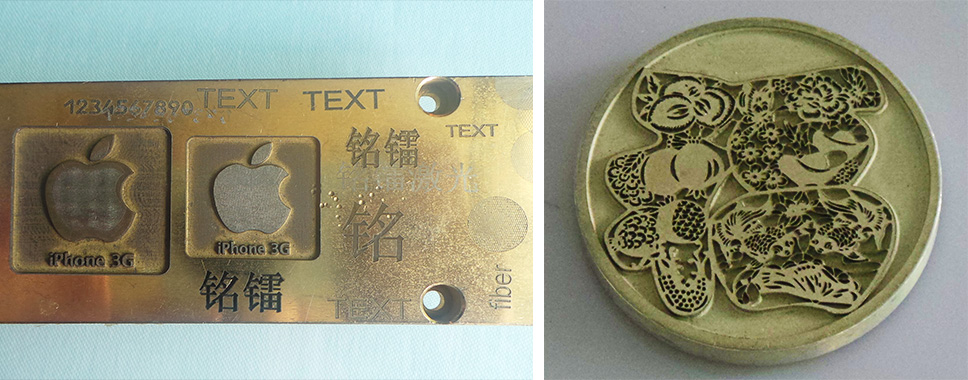

2. Deep engraving: Utilising high power laser this process vaporizes a material to fell into the base metal.Most common in epurasitiki jekiseni molds, Jewelry kugadzira, uye stamping anofa.

3.Ablation: Kubvisa mishonga yepamusoro (kureva plating, uye machira epende) kugadzira translucent back round pasina kukuvadza base base material, inoshandiswa zvakanyanya mu backlit material processing semabhatani ekudzokera shure.

Application Scenarios

Vhidhiyo uye Nhau dzechigadzirwa ichi

Nzira yekuchenesa sei welding nzvimbo?

musi waKubvumbi 21,2022

Nzira yekuchenesa sei welding nzvimbo?

musi waKubvumbi 21,2022

Nzira yekuchenesa sei welding nzvimbo?

musi waKubvumbi 21,2022

kumbira mutengo wakanakisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu