- Thepa e iketsang ea Laser Welding

- Mochini oa Welding oa Laser o tšoaroang ka letsoho

- Mochini oa ho itšeha ka Laser

- Mochini oa ho Seha oa Laser oa Size Precision Fiber e nyane

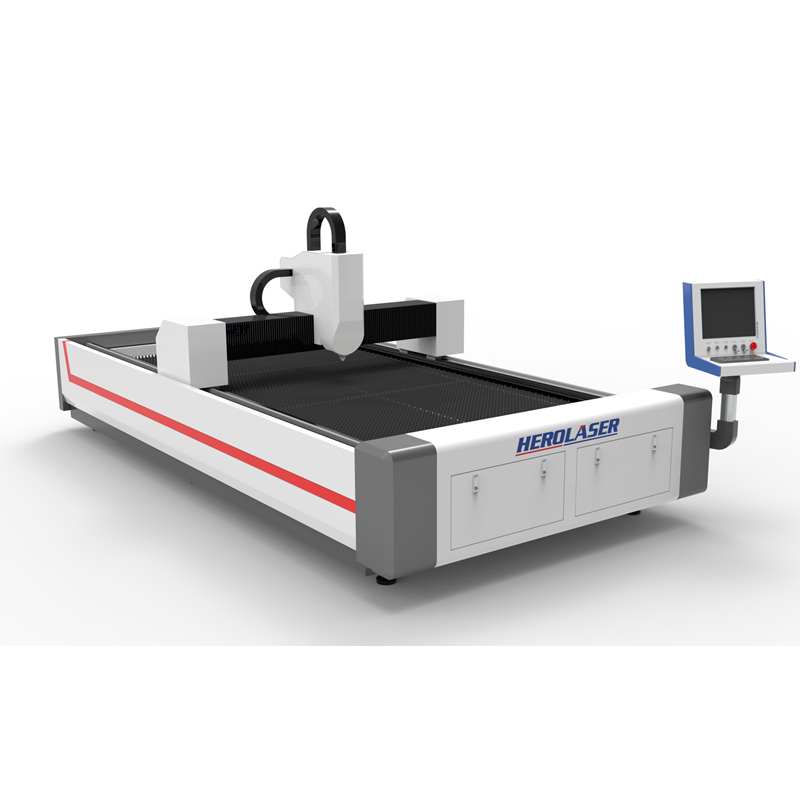

- Mochini oa ho itšeha oa Laser (3015 letoto)

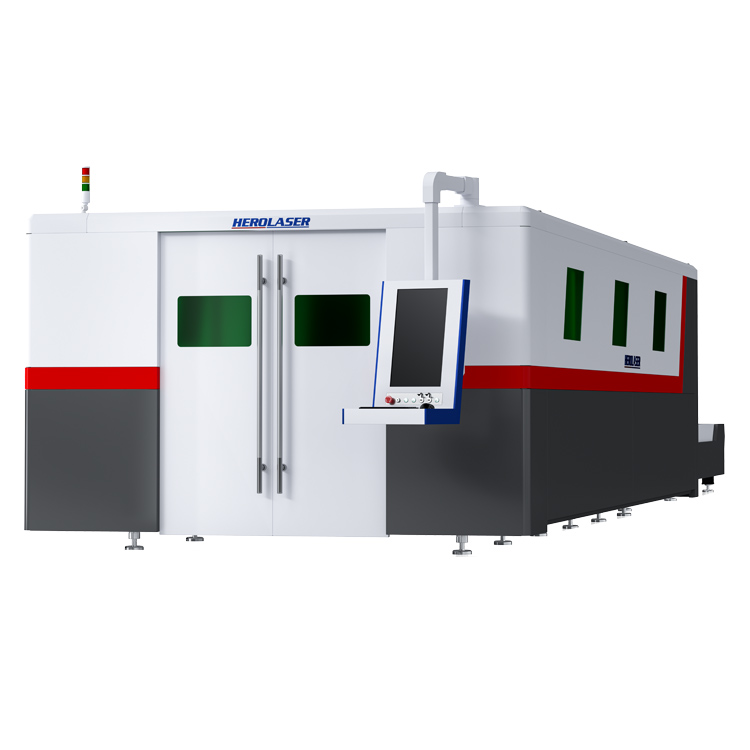

- Fiber Laser Cutting Machine (6025 letoto)

- Mochini oa ho Seha ka Laser Bakeng sa Metal Sheet/Plate (ML-CB-3015FB)

- Tube Laser Cutting Machine (6016 Series)

- Mochini oa ho itšeha oa Tube Laser (QX letoto)

- Mochini oa ho hloekisa Laser

- Mochini oa ho tšoaea oa Laser

Tube Laser Cutting Machine (6016 Series)

Kenyelletso ea Sehlahisoa

Tekheniki Parameters

| LEBITSO LA MORERO | LE NOMORO |

| Moetso oa lisebelisoa | ML-CP-6016DQ-GS |

| Matla a hlahisoang ke laser | 1.5KW |

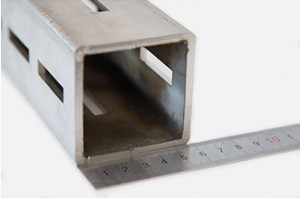

| Chuck clamping range | Φ20mm~Φ160mm, □20 ~ □110 |

| Boholo ba boima ba tube e le 'ngoe | 60KG |

| Bolelele ba ho fepa | ≤6300mm(Ho fepa ka tsela e iketsang) |

| Bolelele ba ho koala | ≤2500mm(Bolelele bo ka khonehang) |

| Ho khaola botenya (e amanang le matla a laser) | tšepe ea carbon≤6mm;tšepe e sa hloekang≤4mm;Aluminium motsoako≤3mm;Brass≤2mm; |

| Ho beha ka nepo | ≤± 0.05mm |

| Ho nepahala ha boemo bo phetoang | ≤± 0.03mm |

| Lebelo le phahameng la X-axis | ≤150m/min |

| Lebelo le phahameng la Y-axis | ≤120m/min |

| Boholo ba lebelo la z-axis | ≤65m/min |

| B axis boholo lebelo | ≤150RPM |

| Ho potlakisa sefofa-sebakeng | 1.2G |

| Tlhokahalo ea motlakase | AC380V±5%/50Hz |

| Tšebeliso ea matla a mochine | 6KW-25KW |

| Litekanyo tsa Kabinete | 11000*2500*2300(mm) |

| Boima ba mochini | ≈ 6000KG |

| Tšehetso bakeng sa liforomo tsa litšoantšo | IGS/SAT/JHB |

Likarolo tsa mantlha

1. Thepa ea mohatla e ka fihla ho 0-60mm;

2. Litšenyehelo tse tlase haholo tsa ts'ebetso le tlhokomelo;

3. Hlooho ea ho itšeha ka laser e ke ke ea ikopanya le holim'a thepa 'me e ke ke ea senya workpiece;

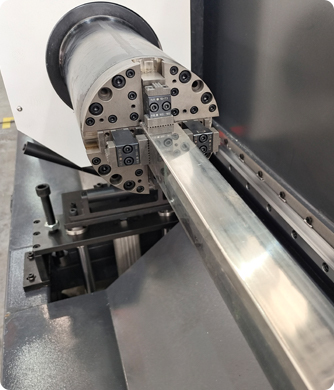

4. The chuck ka pele clamps setorouku feletseng ntle le ho fetola mehlahare;

5. Ho tsamaea ka lebelo le phahameng la sefofane, ho potlakisa ho hoholo, ho arabela ka potlako, le likhutlong ha ho bonolo ho chesa;

6. Moea o fofang mohatleng oa karete e ka morao, lerako la phala le hloekile, 'me lerōle le sehang le mosi li fokotseha;

7. Bophahamo ba lebili la tšehetso e tsitsitseng ea ho fepa bo ka fetoloa ka letsoho, 'me letsoapo la ho fepa le thellela fatše motsoako;

8. Ho itšeha ka lebelo le phahameng le boleng bo phahameng ba laser ho ka etsoa ka li-profiles tse kang li-tubes tse chitja, li-square tubes, li-tubes tse nang le li-rectangular, le li-tubes tse pota-potileng thekeng;

9. Karolo ea ho itšeha ea pipe e boreleli ntle le li-burrs, ha e na slag, ha e na blackening, ha e na mosehla, 'me e ka lemoha habonolo ho khaola ha litšoantšo tse sa tšoaneng tse rarahaneng.

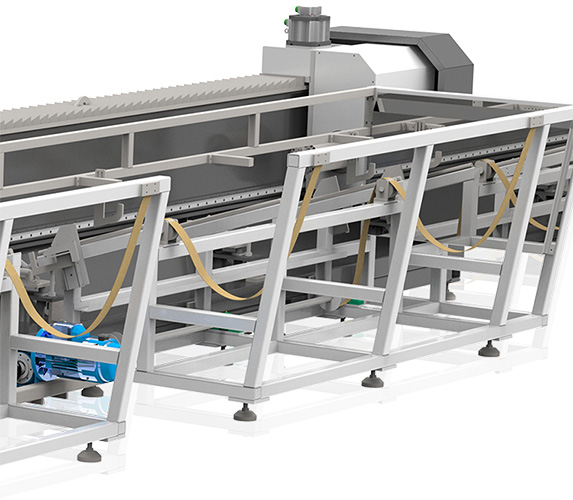

Ho fepa ka potlako

Sebopeho sa 'mele oa mochini o sehang liphaephe o ntlafalitsoeng bakeng sa ho fepa ka boiketsetso

Sebaka se pakeng tsa boemo ba ho leta le boemo ba ho sebetsa se khuts'oane haholo, se fetang 90% ka potlako ho feta lebelo la ho fepa la lithaka tsa lithaka.

Sebaka sa ho itšeha se hloekile ebile ha se na likoli

Karolo ea ho khaola liphaephe e tla ba e boreleli ntle le burr, slag, blackening le mosehla;E ke ke ea kopana le bokaholimo ba lintho tse bonahalang le ho phunya workpiece.E ka lemoha habonolo ho foka mohatla oa karete ka mor'a ho khaola litšoantšo tse fapaneng tse rarahaneng.Lerako la liphaephe le hloekile 'me lerōle le sehang le mosi li fokotseha

Bokhoni ba ho seha lipeipi tsa setsebi

Chuck e ka pele e tšoara setorouku se feletseng ntle le ho fetola claw.The chuck e ka morao e phunyeletsoa mohatleng, lerako la pipe le hloekile, lerōle le sehang le mosi li fokotsehile, sekoti se se nang letho ke lebelo le phahameng, ho potlakisa ho hoholo, karabo ea ho itšeha e potlakile, 'me sekhutlo ha se bonolo ho chesa.

Setšoantšo sa 'nete sa mochini oa ho seha lipeipi tsa laser

Maemo a Kopo

Ho fepa ho tsitsitse, bophahamo ba lebili le tšehetsang bo ka fetoloa ka letsoho, 'me letsoapo le se nang letho le kopantsoe le ho thella;E khona ho itšeha ka lebelo le phahameng le boleng bo phahameng ba laser holim'a tube e chitja, tube ea lisekoere, tube e nang le mahlakore a mabeli, letheka le li-profiles tse ling.

Lifitio le Litaba tsa sehlahisoa sena

Fiber Laser Cutting Machine

ka la 21 Mmesa,2022

Fiber Laser Cutting Machine

ka la 21 Mmesa,2022

Mochini oa ho itšeha ka Laser

ka la 21 Mmesa,2022

kopa theko e ntle ka ho fetisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu