Ho Hloekisa Laser: Tšebeliso ea Theknoloji ea ho Hloekisa Laser ea Indasteri

Li-substrates tse sebetsang

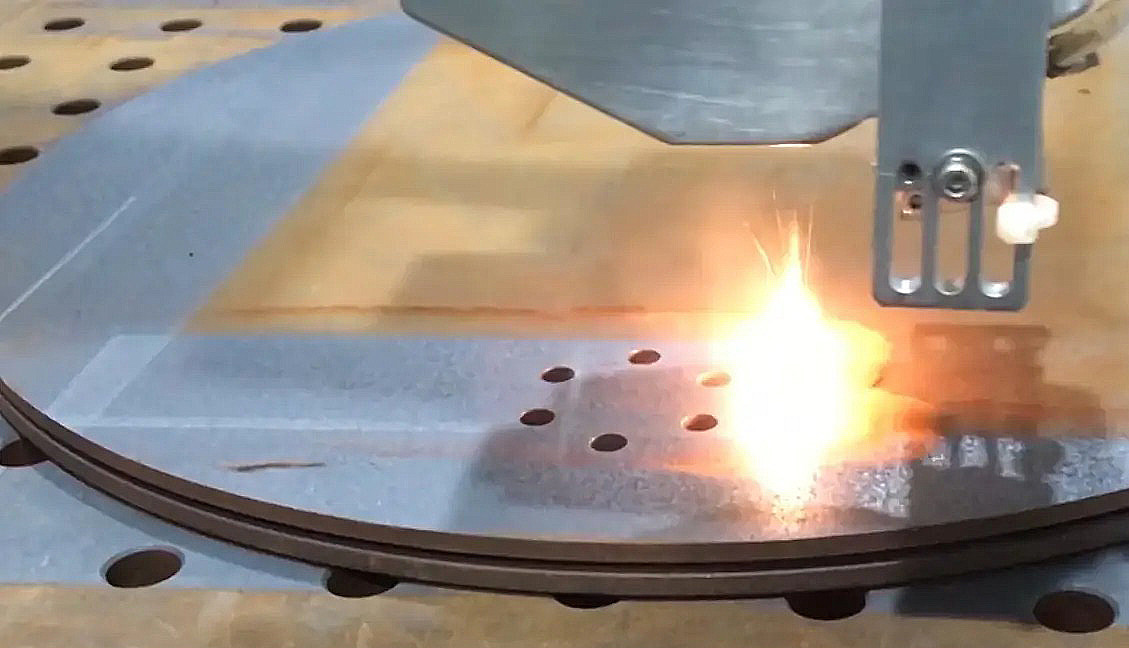

Sebakeng sa ts'ebeliso ea indasteri, ntho ea ho hloekisa laser e arotsoe likarolo tse peli: substrate le lisebelisoa tsa ho hloekisa.The substrate haholo-holo e na le lera la tšilafalo holim'a litšepe tse fapa-fapaneng, li-chips tsa semiconductor, li-ceramics, lisebelisoa tsa makenete, li-plastiki le likarolo tsa optical.Lisebelisoa tsa ho hloekisa li kenyelletsa litlhoko tse pharaletseng tsa ts'ebeliso ea ho tlosa mafome, ho tlosa pente, ho tlosa letheba la oli, ho tlosa filimi / oxide layer le resin, sekhomaretsi, lerōle le ho tlosoa ha slag tšimong ea indasteri.

Melemo ea ho Hloekisa Laser

Hona joale, mekhoa ea ho hloekisa e sebelisoang haholo indastering ea ho hloekisa e kenyelletsa ho hloekisa ka mechine, ho hloekisa lik'hemik'hale le ho hloekisa ka ultrasonic, empa kopo ea bona e fokotsehile haholo tlas'a lithibelo tsa tšireletso ea tikoloho le litlhoko tsa 'maraka o nepahetseng haholo.Melemo ea mochini o hloekisang oa laser o hlahelletse ts'ebelisong ea liindasteri tse fapaneng.

1. Mohala oa kopano o ikemetseng: mochine o hloekisang oa laser o ka kopanngoa le lisebelisoa tsa mochine oa CNC kapa liroboto ho kenya ts'ebetsong ea ho laola le ho hloekisa ka thōko, e ka khonang ho lemoha ho iketsetsa lisebelisoa le ho etsa ts'ebetso ea mohala oa lihlahisoa le ts'ebetso e bohlale.

2. Boemo bo nepahetseng: sebelisa fiber ea optical ho fetisetsa le ho tataisa laser ho etsa hore e tenyetsehe, le ho laola sebaka hore se tsamaee ka lebelo le phahameng ka galvanometer ea scanning e hahiloeng, e le ho thusa ho hloekisa ka laser e sa amaneng le likhutlo. tseo ho leng thata ho li fihlela ka mekhoa ea khale ea ho hloekisa, joalo ka likarolo tse bōpehileng ka ho khetheha, likoti le li-grooves.

3. Ha ho na tšenyo: tšusumetso ea nako e khutšoanyane e ke ke ea futhumatsa holim'a tšepe 'me e ke ke ea senya substrate.

4. Botsitso bo botle: laser ea pulse e sebelisoang mochine oa ho hloekisa laser e na le bophelo bo bolelele ba tšebeletso ea ultra, hangata ho fihlela lihora tsa 100000, boleng bo tsitsitseng le botšepehi bo botle.

5. Ha ho na tšilafalo ea tikoloho: ha ho na sesebelisoa sa ho hloekisa lik'hemik'hale se hlokahalang 'me ha ho na metsi a litšila a hloekisang a hlahisoang.Likaroloana tse silafetseng le khase tse hlahisoang nakong ea ho hloekisa ka laser li ka bokelloa habonolo le ho hloekisoa ke fene e nkehang ea mosi ho qoba tšilafalo ea tikoloho.

6. Litšenyehelo tse tlaase tsa tlhokomelo: ha ho lisebelisoa tse sebelisoang nakong ea tšebeliso ea mochine oa ho hloekisa laser, 'me litšenyehelo tsa ts'ebetso li tlaase.Ha nako e ntse e ea, ke lilense feela tse lokelang ho hloekisoa kapa ho nkeloa sebaka khafetsa, ka litšenyehelo tse tlase tsa tlhokomelo le haufi le ho lokisoa mahala.

Indasteri ea likopo

Lisebelisoa tse tloaelehileng tsa ho hloekisa ka laser li kenyelletsa: ho hloekisa hlobo, ho tlosa mafome a indasteri, pente ea khale le ho tlosoa ha filimi, ho tjheseletsa pele le ho tjheseletsa ka poso, ho tlosoa ha ester ea likarolo tse nepahetseng, ho tlosa litšila le ho tlosoa ha lesela la oxidation ea likarolo tsa elektronike, ho hloekisa mesaletsa ea setso, joalo-joalo. ka metallurgy, hlobo, likoloi, lisebelisoa tsa hardware, lipalangoang, lisebelisoa tsa kaho, mechine le liindasteri tse ling.

Nako ea poso: Apr-11-2022