- Thepa e iketsang ea Laser Welding

- Mochini oa Welding oa Laser o tšoaroang ka letsoho

- Mochini oa ho itšeha ka Laser

- Mochini oa ho Seha oa Laser oa Size Precision Fiber e nyane

- Mochini oa ho itšeha oa Laser (3015 letoto)

- Fiber Laser Cutting Machine (6025 letoto)

- Mochini oa ho Seha ka Laser Bakeng sa Metal Sheet/Plate (ML-CB-3015FB)

- Tube Laser Cutting Machine (6016 Series)

- Mochini oa ho itšeha oa Tube Laser (QX letoto)

- Mochini oa ho hloekisa Laser

- Mochini oa ho tšoaea oa Laser

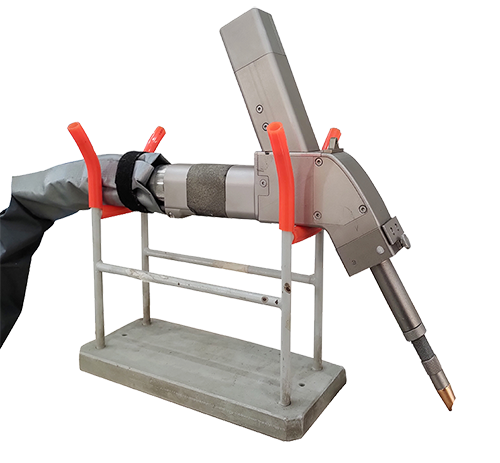

Handheld Fiber Laser Welding Machine (Euro Version)

Kenyelletso ea Sehlahisoa

Lithekiso tse ngata 'marakeng li laoloa ke ho tjheseletsa ka letsoho ho pholileng ka metsi.Welding e pholileng ka letsoho e ts'oaroang ka letsoho e sebelisa metsi e le mokhoa oa ho futhumatsa.Khampani ea rona e rekisa mechine ea ho tjheseletsa e pholileng ka metsi e nang le matla a fapaneng a kang 500W, 800W, 1000W, 1500W, 2000W, 3000W, joalo-joalo 'Me welding e tšoaroang ka letsoho e shebana le mehlala e meraro: 1000W, 1500W, le 2000W.

Likarolo tsa mochini oa tjheseletsa o hahelletsoeng ka letsoho o nang le metsi: o hahelletsoeng ka har'a liindasteri tse peli tse laolang mocheso o le mong, taolo e sa feleng ea mocheso le ho felloa ke mocheso, ho netefatsa ho felloa ke mocheso oa likarolo tsa mantlha tsa optical.Ka fiber laser, e tsitsitseng le e sebetsang hantle

Tekheniki Parameters

| Matla a Laser | 1000W/1500W/2000W/3000W |

| Laser wavelength | 1070nm |

| Bolelele ba Fiber | Tlhophiso e tloaelehileng: 10M, tšehetso e phahameng: 15m |

| Mokhoa oa ts'ebetso | Tsoela pele/ Ketso ya ho fetofetoha |

| Lebelo la lebelo la mochini oa welding | 0-120 limilimithara/s |

| Mochini oa ho futhumatsa metsi | Tanka ea metsi ea thermostatic ea indasteri |

| Ambient Mocheso | 15 ~ 35 ℃ |

| Ambient Humidity | <70% ha ho condensation |

| Botenya ba tjheseletsa | 0.5-3 limilimithara |

| Litlhoko tsa lekhalo | ≤0.5mm |

| Voltage e sebetsang | AC220V |

| Boholo | 1100mm x 570mm x 1180mm |

| Boima ba 'mele | 220kg |

Likarolo tsa mantlha

1. WOBBLE hlooho ea laser e tšoaroang ka letsoho, e bobebe ebile e tenyetseha, e ka tjheseletsa karolo efe kapa efe ea sesebediswa

2. E hahelletsoeng ka har'a liindasteri tse peli tse laolang mocheso o le mong

3. Taolo ea kamehla ea mocheso le ho senya mocheso ho etsa bonnete ba hore mocheso oa mocheso oa likarolo tsa mantlha tsa optical circuit.

4. Ts'ebetso e bonolo, e ka sebetsoa habonolo ka koetliso e bonolo

5. Lihlahisoa tse ntle li ka chesetsoa ho nka ntle le monghali

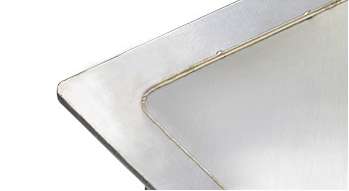

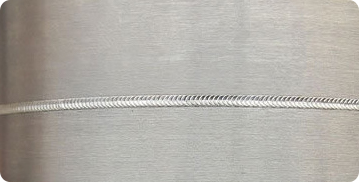

Ho chesoa ha fillet

Ho tjheseletsa seropeng

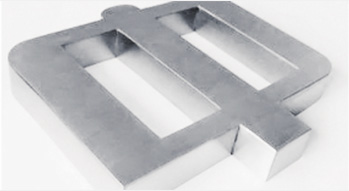

Welding ea seroki

Sebetsa ka ho roka

Thekenoloji ea swing welding ea lenonyeletso le cheselitsoeng

The wobble welding joint e ntlafalitsoe ka boikemelo, ka mokhoa oa swing welding, bophara bo feto-fetohang le mamello e matla ea welding, e etsang hore ho be le moeko oa sebaka se senyenyane sa welding ea laser, e eketsa boholo ba mamello le bophara ba weld ea likarolo tsa ts'ebetso, 'me e fumana sebopeho se betere sa weld. .

1. Betere tjheseletsa formability le boleng bo phahameng letheba tjheseletsa

2. Fuselage le hlooho ea laser li na le litlhoko tse tlase tsa matla a laser

3. Sebaka se lumelletsoeng sa bophara ba weld se tla atolosoa, 'me weld e tla ba ntle ntle le deformation

4. Bokhoni bo botle ba aluminium alloy bonding, boleng bo phahameng ba ho sebetsana le ho pheta-pheta le botsitso

Maemo a Kopo

Mochini ona o tšoaroang ka letsoho oa laser o loketse ho cheselletsa khauta, silevera, titanium, nickel, tin, koporo, aluminium le tšepe e 'ngoe le lisebelisoa tsa eona tsa alloy, o ka fihlela ts'ebetso e ts'oanang e nepahetseng pakeng tsa tšepe le litšepe tse sa tšoaneng, e' nile ea sebelisoa haholo lisebelisoa tsa sefofane. , ho haha likepe, lisebelisoa, lihlahisoa tsa mechine le tsa motlakase, likoloi le liindasteri tse ling.

Litaba tse amanang le lihlahisoa le livideo

Mochini oa Welding oa Laser

ka la 21 Mmesa,2022

Mochini oa Welding oa Laser

ka la 21 Mmesa,2022

Mochini oa Welding oa Laser

ka la 21 Mmesa,2022

ka la 21 Mmesa,2022

Bophelong ba rona ba letsatsi le letsatsi, re ke ke ra phela ntle le kichine le ntloana.Kichine ea sejoale-joale le kamore ea ho hlapela e kenyelletsa siling, kichineng le thepa ea ho hlapela ...

ka la 21 Mmesa,2022

Bophelong ba rona ba letsatsi le letsatsi, re ke ke ra phela ntle le kichine le ntloana.Kichine ea sejoale-joale le kamore ea ho hlapela e kenyelletsa siling, kichineng le thepa ea ho hlapela ...

ka la 21 Mmesa,2022

Bophelong ba rona ba letsatsi le letsatsi, re ke ke ra phela ntle le kichine le ntloana.Kichine ea sejoale-joale le kamore ea ho hlapela e kenyelletsa siling, kichineng le thepa ea ho hlapela ...

Tlhahlobo ea matla a ho tjheseletsa ka laser

| Matla a laser | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Lintho tse bonahalang | botenya | |||||||||

| Ts'epe e sa beng le mabali | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Tšepe ea carbon | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Aluminium | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

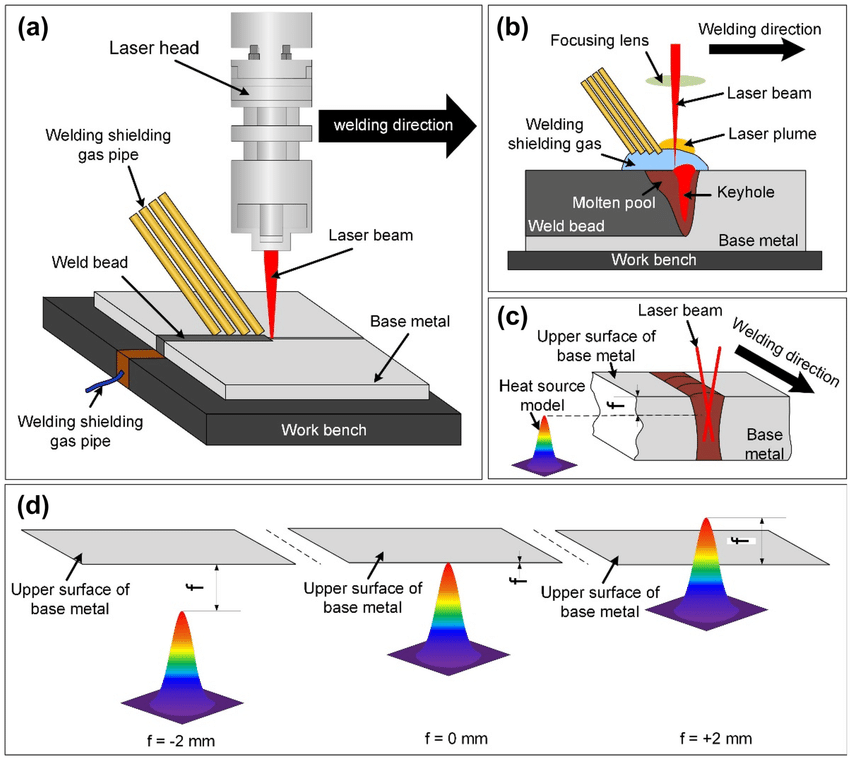

Setšoantšo sa moralo oa ts'ebetso ea welding ea laser:

Mefuta e fapaneng ea laser welding:

| Mofuta oa laser | Wavelength | Mokhoa oa ho tsoa | Kopo |

| CW fiber laser | 1070nm | Tsoelang pele | tjheseletsa nako le nako / e tsoelang pele ea tšepe e tšoanang Modulated pulse spot welding |

| laser ea YAG | 1064nm | Pulse | Spot welding/weld seam applications tsa tšepe e tšoanang |

| QCW fiber laser | 1070nm | Pulse/ E tsoelang pele | Metal Spot Welding / Continuous Seal Welding |

| Laser ea semiconductor | 808nm, 915nm, 980nm | Pulse/ E tsoelang pele | Plastiki Welding / Laser Soldering |

HEROLASER Lethathamo la Sehlahisoa sa Lisebelisoa tsa Laser tse Bohlale

Bakeng sa ho reka ka bongata kapa lihlahisoa tse ikhethileng, ka kopo ikopanye le litšebeletso tsa bareki ba inthaneteng, kapasiea molaetsa.

U ka boela ua romela imeile hosales@herolaser.net.

kopa theko e ntle ka ho fetisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu