Handheld Laser Welding Machine (Standard)

Product Introduction

Having it firstly invented by Herolaser, the handheld welding machine comes into existing with the latest generation of fiber laser, automatic wire feeder and newly developed wobble welding head, which makes it completely unique to fill the gap of handheld laser welding market.

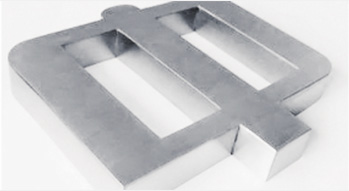

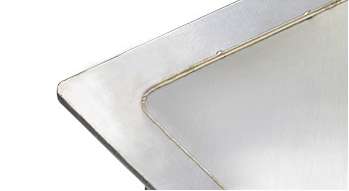

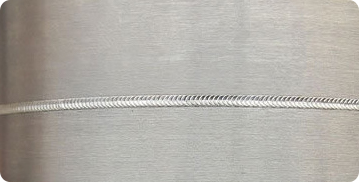

With simple instructions, the machine works into a perfect welding pool in a decent amount of time and requires no consumables electrode, which perfectly replaces the processing way of traditional manual metal arc welding machines over thin stainless-steel plate, iron plate and galvanized plate. Thanks to its welding flexibility on irregular shapes of workpieces, the machine is widely used in kitchen cabinets and utensils, stairs handrails and elevators, store racks, ovens, door and window guard bars, power distribution boxes, stainless steel furniture and others industries.

The machine adopts user-friendly design and upgraded technology, in comparison with traditional welding equipment, making welders working in more effective, safe, energy saving and environmental-friendly way. The welding speed is 3 to 10 times faster than ever while it comes in handy and greatly cover your budgets. Herolaser handheld welding machine – make welders love their jobs even more.

Application Scenarios

This handheld laser welding machine is suitable for welding of gold, silver, titanium, nickel, tin, copper, aluminum and other metal and its alloy material, can achieve the same precision welding between metal and dissimilar metals, has been widely used in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, automotive and other industries.

Technical Parameters

|

Laser Power |

1000W/ 1500W/ 2000W/ 3000W |

|

Laser wavelength |

1070nm |

|

Fiber Length |

Standard configuration: 10M, maximum support: 15m |

|

Operation Mode |

Continuous / modulation |

|

Welding machine speed range |

0-120 mm/s |

|

Cooling water machine |

Industrial thermostatic water tank |

|

Ambient Temperature |

15~35 ℃ |

|

Ambient Humidity |

< 70% no condensation |

|

Welding thickness |

0.5-3mm |

|

Gap requirements |

≤0.5mm |

|

Working Voltage |

AC220V |

|

Size |

1100mm x 570mm x 1180mm |

|

Weight |

220kg |

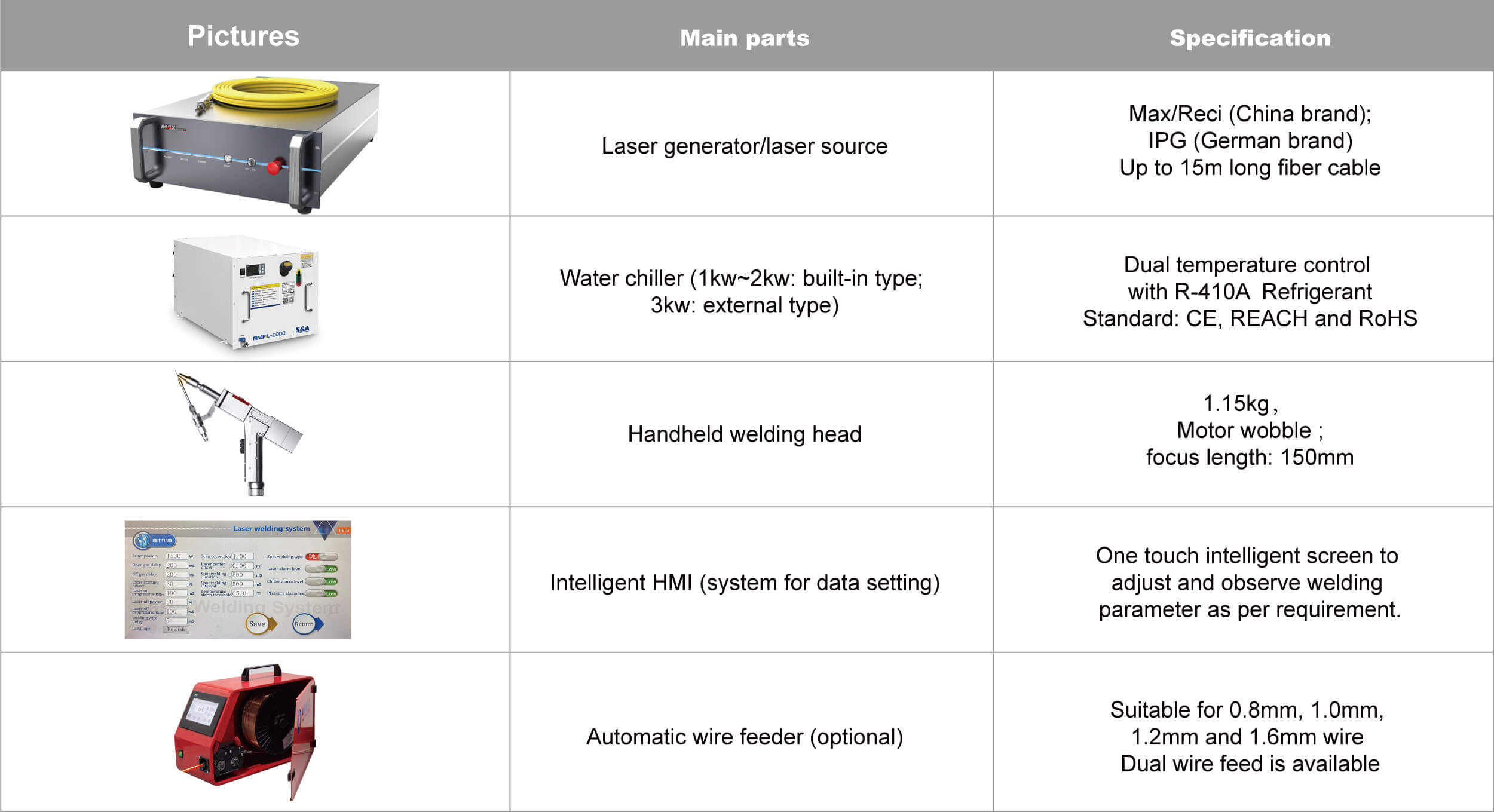

Configuration

Laser welding power analysis

|

Laser power |

1000W |

1500W |

2000W |

3000W |

4000W |

6000W |

8000W |

10000W |

12000W |

|

| Material | thickness | |||||||||

|

Stainless steel |

1 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

|

3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||

|

4 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

5 |

√ |

√ |

√ |

√ |

√ |

√ |

||||

|

6 |

√ |

√ |

√ |

√ |

√ |

√ |

||||

|

8 |

√ |

√ |

√ |

√ |

||||||

|

10 |

√ |

√ |

√ |

|||||||

|

12 |

√ |

√ |

||||||||

|

15 |

√ |

|||||||||

|

20 |

||||||||||

|

25 |

||||||||||

|

30 |

||||||||||

|

40 |

||||||||||

|

Carbon steel |

1 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||

|

3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

4 |

√ |

√ |

√ |

√ |

√ |

√ |

||||

|

5 |

√ |

√ |

√ |

√ |

√ |

|||||

|

6 |

√ |

√ |

√ |

√ |

||||||

|

8 |

√ |

√ |

√ |

√ |

||||||

|

10 |

√ |

√ |

√ |

|||||||

|

12 |

√ |

√ |

√ |

|||||||

|

15 |

√ |

√ |

||||||||

|

20 |

√ |

|||||||||

|

25 |

||||||||||

|

30 |

||||||||||

|

40 |

||||||||||

|

Aluminum |

1 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|

2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||

|

3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

4 |

√ |

√ |

√ |

√ |

√ |

√ |

||||

|

5 |

√ |

√ |

√ |

√ |

√ |

|||||

|

6 |

√ |

√ |

√ |

√ |

||||||

|

8 |

√ |

√ |

||||||||

|

10 |

√ |

|||||||||

|

12 |

||||||||||

|

15 |

||||||||||

|

20 |

||||||||||

|

25 |

||||||||||

|

30 |

||||||||||

Different types of laser welding:

|

Laser type |

Wavelength |

Output mode |

Application |

| CW fiber laser | 1070nm | Continuous | Intermittent/continuous welding of the same metal Modulated pulse spot welding |

| YAG laser | 1064nm | Pulse | Spot welding/weld seam applications of the same metal |

| QCW fiber laser | 1070nm | Pulse/continuous | Metal Spot Welding / Continuous Seal Welding |

| Semiconductor laser | 808nm,915nm,980nm | Pulse/continuous | Plastic Welding/Laser Soldering |

HEROLASER Intelligent Laser Processing Equipment Product Catalog

For bulk purchases or customized products, please contact online customer service, or leave a message.

You can also send email to sales@herolaser.net.