- Izixhobo ze-Laser Welding ezizenzekelayo

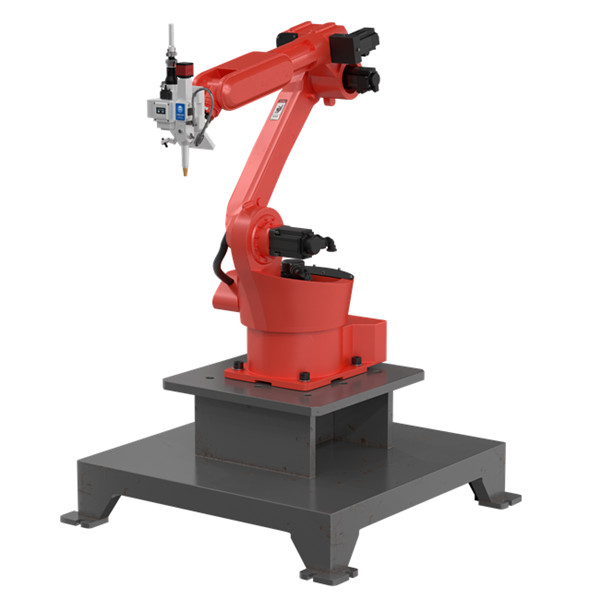

- I-Automatic Fiber Laser Welding Robot

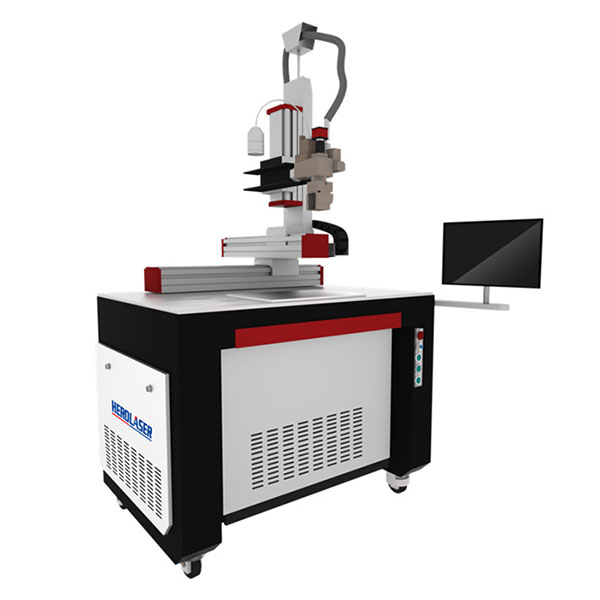

- 3/4/6 Axis Umatshini wokuWelding weLaser ozenzekelayo

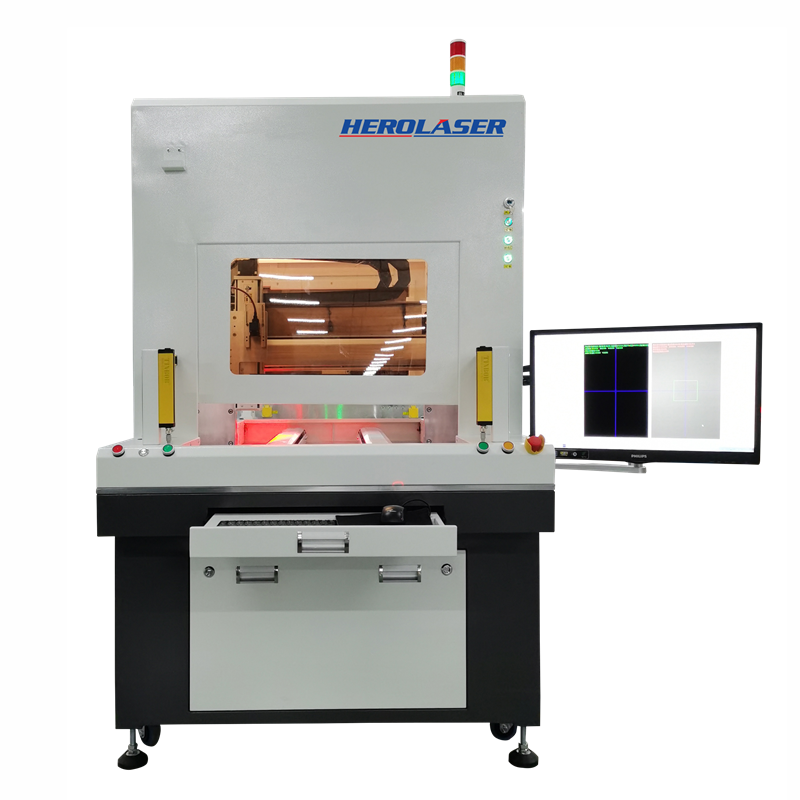

- Amandla aphezulu 12KW Laser Welding Machine

- Ukulungisa uMngundo i-YAG Laser Welding Machine

- Isikhululo esiphindwe kabini sobushushu obungaguqukiyo kumatshini wokuthambisa we-laser

- Iiglasi umatshini welding oluzenzekelayo laser

- Umatshini wokuWelding weLaser ophathwa ngesandla

- Umatshini wokusika iLaser

- Ubungakanani obuNcinci obuCwangcisiweyo beFiber Laser Cutting Machine

- Umatshini wokusika iFayibha Laser (3015 series)

- IFayibha Laser Cutting Machine (6025 series)

- ILaser Cutting Machine yeMetal Sheet/Plate (ML-CB-3015FB)

- Tube Laser Cutting Machine (6016 Series)

- Umatshini wokusika umbhobho weLaser (QX series)

- Umatshini wokucoca ngeLaser

- Umatshini wokuMakisha weLaser

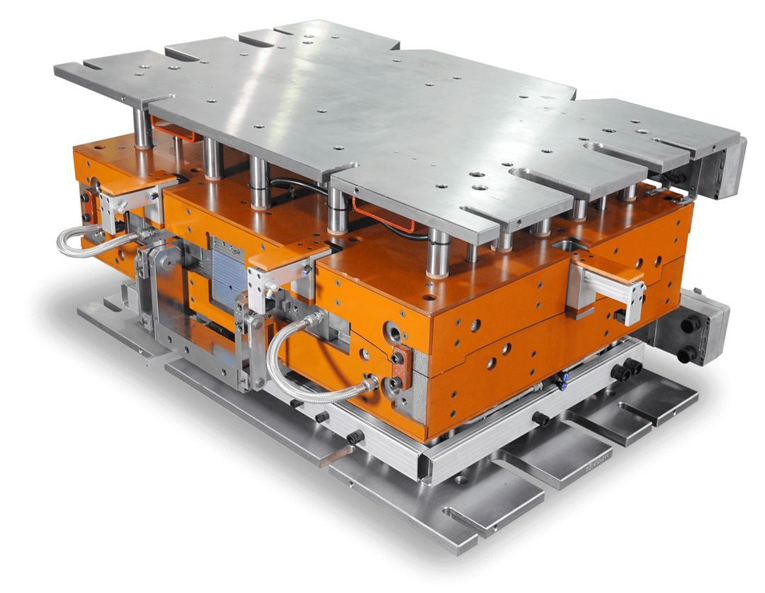

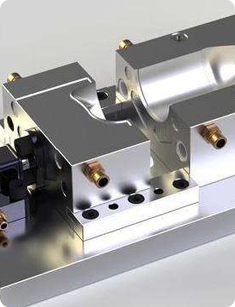

Ukulungisa uMngundo i-YAG Laser Welding Machine

Intshayelelo yeMveliso

I-Herolaser mold yokulungisa uchungechunge lwe-laser welding machine lukhethekileyo kushishino lokubumba lusebenza, lo mzekelo ozinikele ekutshintsheni i-argon welder yendabuko yokulungisa ukubumba okuchanekileyo.Onke amacandelo aphambili alo matshini angeniswa kumazwe angaphandle.Ujongano lwesoftware lusebenzisa iscreen esikhulu seLCD kwaye lubonisa ujongano lweelwimi ezininzi, kulula kwaye kulula ukuyisebenzisela umqhubi.Iimowudi ezininzi zokuseta kwangaphambili, nazo zinokucwangciswa ngabasebenzisi, umsebenzi wememori osisigxina, osebenza kwizinto ezahlukeneyo.

Ixhotyiswe ngenkqubo ekhethekileyo yokujonga i-microscope, ukukhulisa i-10x;Kukho isixhobo sokukhusela i-elektroniki esinesantya esiphezulu sokukhusela amehlo omsebenzisi kumonakalo we-laser, ukunciphisa ukudinwa kwamehlo omqhubi kunye nokuphucula ukusebenza kakuhle.

Inkqubo yokukhusela i-argon ye-synchronous kunye nolawulo lwangaphakathi lwe-microcomputer inokuthintela i-weld ekubeni i-oxidized kwaye yenza i-welding iqine kwaye ihle;IArgon inokugcinwa kowona mlinganiselo mkhulu ngokwamkela ulawulo oluhambelanayo ngokukhutshwa kwelaser

Itanki yamanzi yomatshini wokuwelda i-laser inokufudumeza kwaye ipholise umatshini, kwaye ibeke iliso kubushushu bamanzi ngexesha lokwenyani.Inesimo sobushushu / sokujikeleza rhoqo

Ikhabhinethi yokusingatha i-laser inokubona ngokucacileyo ukuma kwemveliso kunye nefuthe le-welding ngokuhambelana nokukhanya okubomvu

Ibhentshi ephambili yomatshini kunye nendawo apho i-welding workpiece ibekwe khona ilungele ukuba i-laser idibanise i-workpiece.

Iiparamitha zobuGcisa

| UMZEKELO: | I-ML-WY-BP-DB-W200 | I-ML-WY-BP-DB-W400 |

| I-3-axis stroke yebhentshi yomsebenzi | X=300mm,Y=200mm(X,Y inokulungiswa ngesandla kwaye i-z-axis inokuphakanyiswa) | |

| Ukuthwala ibhentshi yomsebenzi | ≤200KG | |

| Ukunikezwa Amandla | 220V±10%/50Hz Okanye 380V±10%/50Hz | |

| Iiparamitha zeLaser | ||

| Uhlobo lweLaser | Nd:YAG pulse | |

| Ukulungelelanisa uluhlu lwendawo yokukhanya | 0.1~0.3mm | |

| Ubungakanani bendawo yokukhanya | 0.2-3.0mm | |

| Ubude beLaser | 1064nm | |

| Ububanzi be-Pulse | 0.5~25ms | |

| Ubuninzi bamandla laser | 200W | 400W |

| Ukuphindaphinda kwe-Pulse | ≤50Hz | |

| Ubude bokujolisa kwimveliso yeLaser | 80mm/100mm/120mm(uyazikhethela) | |

| Ukupholisa iLaser | Ukupholisa amanzi | |

| Inkqubo yokujonga | Imakroskopu (360° iyahlengahlengiswa) | |

| Igesi yokukhusela | Umgca omnye (xenon) | |

| Ipharamitha yesolder | ||

| Idayamitha ye-welding yocingo | 0.1mm~0.8mm | |

Iimpawu eziphambili

1. Indawo echaphazelekayo yokushisa incinci, i-deformation encinci ye-molds echanekileyo.

2. Ubunzulu be-Welding bukhulu, i-welding iqinile.Ukudibanisa okwaneleyo, akukho mikhondo yokulungisa.Akukho ziganeko zintsonkothileyo ekudityanisweni kweendawo ezibonisayo kunye nenxalenye enkulu yesixhobo esinyibilikayo sedama elinyibilikayo.

3. Izinga le-oxidation ephantsi, umbala wamacandelo okucubungula ulungile.

4. Akukho stomata okanye umngxuma wesanti owanyamalalayo emva kwe-welding.

5. Iinxalenye ze-welding zinokucutshungulwa, ngokukodwa zifanelekile kwiimfuno zokupolisha zokulungiswa kwe-mold.

6. Amacandelo okucubungula anokufikelela kwi-50 ukuya kwi-60 yobunzima be-Rockwell.

Akukho deformation of welding kufa

Indawo echaphazelekayo yobushushu incinci, engayi kukhokelela kwi-deformation ye-precision die, kwaye akukho ukudandatheka kwindibaniselwano phakathi kwenxalenye ye-convex yezinto ezityhidiweyo kwi-pool etyhidiweyo kunye ne-matrix.

● Izinga le-oxidation liphantsi kwaye i-workpiece ayiyi kutshintsha umbala emva kwe-welding

● Indawo yokufudumeza incinci, kwaye iindawo ezinomatshini aziyi konakala

● Akuyi kubakho pores okanye trachoma emva kwe-welding

● Emva kwe-welding, inokuthi ifakwe ngaphandle kokuchaphazela umphumo

Iimeko zeSicelo

Ishishini lokungunda

Ukusebenza ngesinyithi

Ukwenziwa koomatshini

Iividiyo kunye neNdaba zale mveliso

Laser Welding Machine

nge-21 ka-Epreli,2022

Laser Welding Machine

nge-21 ka-Epreli,2022

Laser Welding Machine

nge-21 ka-Epreli,2022

cela elona xabiso lilungileyo

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu