Ukucocwa kweLaser: Ukusetyenziswa kweTekhnoloji yokuCoca iLaser yeShishini

IiSubstrates ezisebenzayo

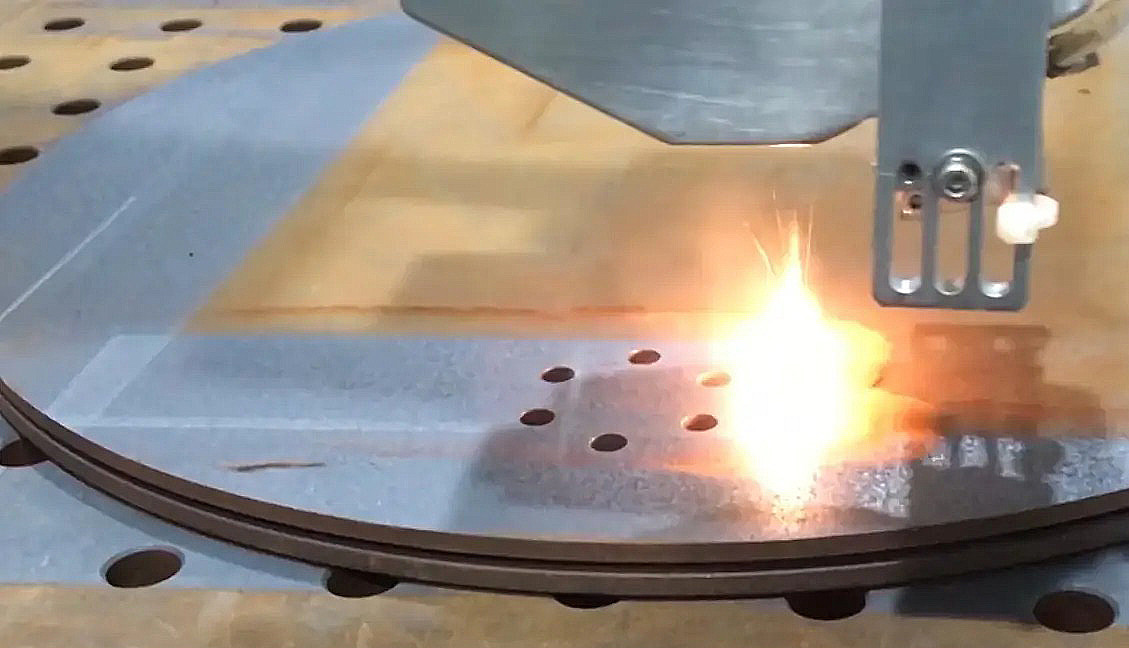

Kwintsimi yesicelo soshishino, into yokucoca i-laser ihlukaniswe ngamacandelo amabini: i-substrate kunye nezinto zokucoca.I-substrate ikakhulu inomaleko wongcoliseko ongaphezulu wesinyithi ezahlukeneyo, iitshiphusi zesemiconductor, iiseramikhi, imathiriyeli kazibuthe, iiplastiki kunye nezinto ezibonakalayo.Izinto zokucoca ikakhulu zibandakanya iimfuno ezibanzi zokususa umhlwa, ukususwa kwepeyinti, ukususwa kwebala leoli, ukususwa kwefilimu / i-oxide layer kunye ne-resin, iglue, uthuli kunye nokususwa kwe-slag kwintsimi yoshishino.

Izinto eziluncedo zokuCoca iLaser

Okwangoku, iindlela zokucoca ezisetyenziswa kakhulu kwishishini lokucoca ziquka ukucocwa komatshini, ukucocwa kweekhemikhali kunye nokucocwa kwe-ultrasonic, kodwa isicelo sabo sinqunyelwe kakhulu phantsi kwemiqobo yokukhuselwa kwendalo kunye neemfuno zeemarike ezichanekileyo.Iinzuzo zomshini wokucoca i-laser zivelele ekusebenziseni amashishini ahlukeneyo.

1. Umgca wokuhlanganisa ngokuzenzekelayo: umatshini wokucoca i-laser unokudibaniswa kunye nezixhobo zomatshini ze-CNC okanye iirobhothi ukuphumeza ulawulo olukude kunye nokucoca, onokuqonda ukuzenzekelayo kwezixhobo kunye nefom yokusebenza komgca wemveliso kunye nokusebenza kwengqondo.

2. Ukubekwa ngokuchanekileyo: sebenzisa i-fiber optical ukuhambisa kunye nokukhokela i-laser ukuyenza ibe bhetyebhetye, kwaye ulawule indawo ukuba ihambe ngesantya esiphezulu nge-galvanometer yokuskena eyakhelweyo, ukwenzela ukuba kube lula ukucocwa kwe-laser engadibananga kwiikona. ekunzima ukufikelela kuzo ngeendlela zokucoca eziqhelekileyo, ezifana neendawo ezikhethekileyo, imingxuma kunye neegrooves.

3. Akukho monakalo: impembelelo yexesha elifutshane ayiyi kutshisa indawo yesinyithi kwaye ayiyi kulimaza i-substrate.

4. Ukuzinza okulungileyo: i-laser ye-pulse esetyenziswe kumatshini wokucoca i-laser inobomi benkonzo ye-ultra, ngokuqhelekileyo ukuya kwiiyure ze-100000, umgangatho ozinzile kunye nokuthembeka okulungileyo.

5. Akukho ngcoliseko lokusingqongileyo: akukho arhente yokucoca iikhemikhali efunekayo kwaye akukho lulwelo lwenkunkuma lokucoca lwenziwayo.Iingqungquthela ezingcolileyo kunye negesi eveliswa kwinkqubo yokucoca i-laser inokuqokelelwa ngokulula kwaye ihlanjululwe yi-fan exhaust ephathekayo ukuphepha ukungcoliseka kwendalo.

6. Iindleko zokugcinwa okuphantsi: akukho zixhobo ezisetyenziswayo ngexesha lokusetyenziswa komatshini wokucoca i-laser, kwaye iindleko zokusebenza ziphantsi.Kwinqanaba lokugqibela, kuphela iilensi ezifuna ukucocwa okanye zitshintshwe rhoqo, ngeendleko eziphantsi zokugcinwa kunye nokusondele ekugcinweni simahla.

Ushishino lwezicelo

Ukusetyenziswa okuqhelekileyo kokucocwa kwe-laser kubandakanya: ukucocwa kokungunda, ukususwa komhlwa kwimizi-mveliso, ipeyinti endala kunye nokususwa kwefilimu, ukuwelda kwangaphambili kunye nonyango lwe-welding ye-post, ukususwa kwe-ester yamacandelo achanekileyo, ukukhutshwa kwe-decontamination kunye ne-oxidation layer ukususwa kwamacandelo e-elektroniki, ukucocwa kwee-relics zenkcubeko, njl. kwisinyithi, ukungunda, iimoto, izixhobo zehardware, ezothutho, izixhobo zokwakha, oomatshini kunye namanye amashishini.

Ixesha lokuposa: Apr-11-2022