- Izixhobo ze-Laser Welding ezizenzekelayo

- I-Automatic Fiber Laser Welding Robot

- 3/4/6 Axis Umatshini wokuWelding weLaser ozenzekelayo

- Amandla aphezulu 12KW Laser Welding Machine

- Ukulungisa uMngundo i-YAG Laser Welding Machine

- Isikhululo esiphindwe kabini sobushushu obungaguqukiyo kumatshini wokuthambisa we-laser

- Iiglasi umatshini welding oluzenzekelayo laser

- Umatshini wokuWelding weLaser ophathwa ngesandla

- Umatshini wokusika iLaser

- Ubungakanani obuNcinci obuCwangcisiweyo beFiber Laser Cutting Machine

- Umatshini wokusika iFayibha Laser (3015 series)

- IFayibha Laser Cutting Machine (6025 series)

- ILaser Cutting Machine yeMetal Sheet/Plate (ML-CB-3015FB)

- Tube Laser Cutting Machine (6016 Series)

- Umatshini wokusika umbhobho weLaser (QX series)

- Umatshini wokucoca ngeLaser

- Umatshini wokuMakisha weLaser

Umatshini wokuWelding weLaser ophathwa ngesandla (Oqhelekileyo)

Intshayelelo yeMveliso

Ukuba nayo yaqalwa yiHerolaser, umatshini wokuwelda ophathwayo ungena kwisizukulwana samva nje se-fiber laser, i-fiber feeder ezenzekelayo kunye nentloko ye-welding esanda kuphuhliswa, eyenza ukuba ibe yodwa ngokupheleleyo ukuzalisa isithuba semarike yokuwelda i-laser.

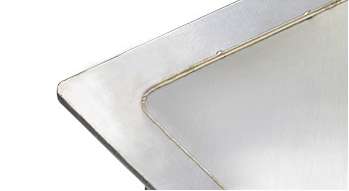

Ngemiyalelo elula, umatshini usebenza kwidama le-welding eligqibeleleyo ngexesha elifanelekileyo kwaye alifuni i-electrode esetyenziswayo, ethatha indawo ngokugqibeleleyo indlela yokulungiswa koomatshini bokuwelda bentsimbi ye-arc ngaphezulu kwepleyiti ebhityileyo yentsimbi, ipleyiti yentsimbi kunye nepleyiti enezinki.Ndiyabulela ukuguquguquka kwe-welding kwiimilo ezingaqhelekanga zezixhobo zokusebenza, umatshini usetyenziswa ngokubanzi kwiikhabhinethi zasekhitshini kunye nezixhobo, izitebhisi zezandla kunye ne-elevators, ii-racks zokugcina, ii-ovens, imivalo yokulinda iifestile, iibhokisi zokuhambisa amandla, ifenitshala yensimbi engenasici kunye namanye amashishini.

Umatshini wamkela uyilo olusebenziseka lula kunye nokuphuculwa kwetekhnoloji, xa kuthelekiswa nezixhobo zemveli ze-welding, ukwenza abashiseli basebenze ngendlela esebenzayo, ekhuselekileyo, yokonga amandla kunye nokusingqongileyo.Isantya se-welding si-3 ukuya kwi-10 ngokukhawuleza kunanini ngaphambili ngelixa isiza kwaye igubungela kakhulu uhlahlo lwabiwo-mali lwakho.Umatshini wokuwelda obambe ngesandla i-Herolaser - yenza abashicileli bathande imisebenzi yabo ngakumbi.

Iiparamitha zobuGcisa

| Amandla eLaser | 1000W/ 1500W/ 2000W/ 3000W |

| Ubude beLaser | 1070nm |

| Ubude beFayibha | Ukucwangciswa okusemgangathweni: 10M, inkxaso ephezulu: 15m |

| Imo yokusebenza | Ukuqhubeka / ukumodareyitha |

| Uluhlu lwesantya somatshini wokuwelda | 0-120 mm/s |

| Umatshini wamanzi okupholisa | Itanki yamanzi ye-industrial thermostatic |

| Ubushushu obugciniwe | 15 ~ 35 ℃ |

| Ukufuma kwe-Ambient | < 70% akukho condensation |

| Ubungqingqwa be-welding | 0.5-3mm |

| Iimfuno ze-Gap | ≤0.5mm |

| I-Voltage esebenzayo | I-AC220V |

| Ubungakanani | 1100mm x 570mm x 1180mm |

| Ubunzima | 220kg |

Iimpawu eziphambili

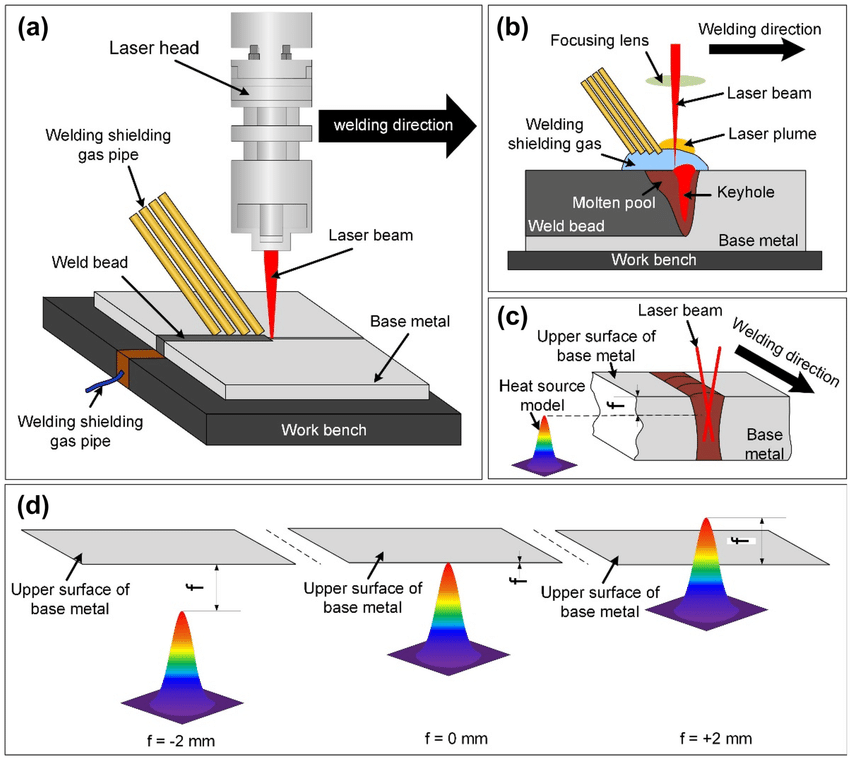

Iteknoloji ye-welding ye-welding ye-welding joint

Umdibaniso we-welding welding uphuhliswa ngokuzimeleyo, kunye nemowudi ye-welding, ububanzi bendawo ehlengahlengiswayo kunye nokunyamezelana okunamandla kwe-welding, eyenza ukungabikho kwendawo yokuwelda i-laser encinci, yandisa uluhlu lonyamezelo kunye nobubanzi be-weld yamacandelo okucubungula, kwaye ifumana ukubunjwa kwe-weld engcono. .

1. I-weld formability engcono kunye ne-high-quality spot welding

2. I-fuselage kunye nentloko ye-laser ineemfuno ezisezantsi zamandla e-laser

3. Uluhlu oluvumelekileyo lobubanzi be-weld luya kwandiswa, kwaye i-weld iya kuba ntle ngaphandle kokuguqulwa

4. Ubuchule obugqwesileyo be-aluminium alloy bonding, umgangatho ophezulu wokuphindaphinda ukuphindaphinda kunye nokuzinza

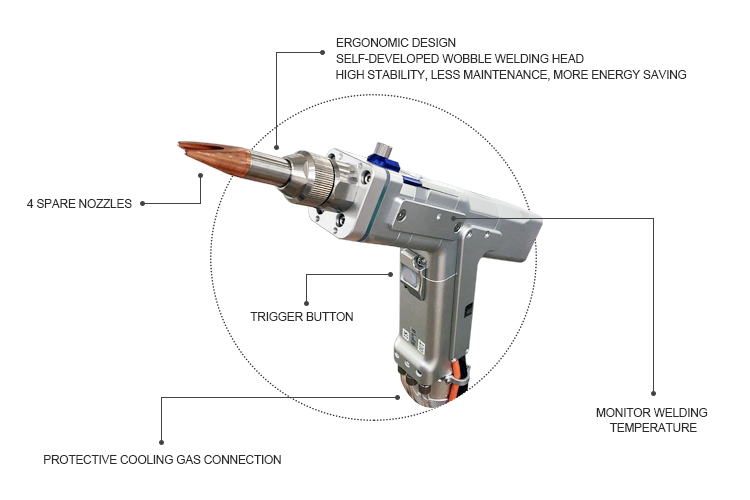

Intloko ye-laser ye-WOBBLE ephathwayo, ilula kwaye iguquguqukayo, inokuwelda nayiphi na indawo yomsebenzi, yenza umsebenzi we-welding usebenze ngakumbi, ukhuselekile, ukonga amandla kunye nokusingqongileyo.

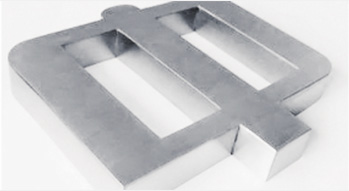

Ukuwelda kweFillet

I-Lap welding

Welding welding

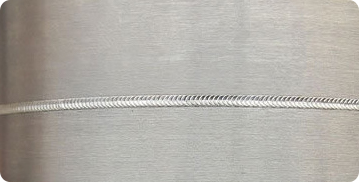

Umthungo welding

Iimpawu zomatshini we-welding we-welding owenziwe ngamanzi

I-built-in-dual-temperature yolawulo lwe-industrial chiller.ukulawulwa kweqondo lokushisa rhoqo kunye nokutshatyalaliswa kobushushu, ukuqinisekisa ukutshatyalaliswa kobushushu be-core optical circuit components.Nge-fiber laser, ezinzile kwaye esebenzayo.

Isikrini sokuchukumisa esidibeneyo

Ukusebenza kwephaneli yokubonisa iilwimi ezininzi, kulula ukuyiqonda, akukho mava afunekayo, uqeqesho lwasimahla, kulula ukuyiqonda

I-fuselage eqinileyo

I-fuselage yenziwe ngezinto ezinzima, ezizinzileyo, ezinokwethenjelwa, ukugcinwa okuncinci kunye nokuzinza

10-15m intambo yefiber optical

Intambo ye-fiber optical eyi-10-15m ilungelelaniswe phakathi kwentloko ye-laser kunye nomninimzi, olungele ukuwelda kunye nesicelo esiguquguqukayo.

Iimeko zeSicelo

Lo matshini wokuwelda ngesandla we-laser ufanelekile ukuwelda igolide, isilivere, i-titanium, i-nickel, i-tin, i-copper, i-aluminiyam kunye nezinye isinyithi kunye ne-alloy material yayo, inokufikelela kwi-welding efanayo echanekileyo phakathi kwesinyithi kunye nesinyithi esingafaniyo, isetyenziswe ngokubanzi kwizixhobo ze-aerospace. , ukwakhiwa kweenqanawa, izixhobo zokusebenza, oomatshini kunye neemveliso zombane, iimoto kunye namanye amashishini.

Uhlalutyo lwamandla we-laser welding

| Amandla eLaser | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Izinto eziphathekayo | ubukhulu | |||||||||

| Yenziwe ngentsimbi eshayinayo | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Intsimbi yekhabhoni | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Aluminiyam | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

Umzobo wenkqubo ye-laser welding:

Iintlobo ezahlukeneyo ze-laser welding:

| Uhlobo lweLaser | Ubude bamaza | Imo yokuphuma | Isicelo |

| CW ifayibha laser | 1070nm | Ngokuqhubekayo | Ukuwelda okungapheliyo/okuqhubekayo kwentsimbi efanayo Modulated pulse spot welding |

| YAG laser | 1064nm | Ukubetha | Ukufakwa kwe-spot welding / weld seam yentsimbi efanayo |

| QCW ifayibha laser | 1070nm | Ukubetha kwentliziyo/okuqhubekayo | Metal Spot Welding / Continuous Seal Welding |

| I-laser ye-semiconductor | 808nm, 915nm, 980nm | Ukubetha kwentliziyo/okuqhubekayo | Ukuwelda kwePlastiki/I-Laser Soldering |

I-HEROLASER Ikhathalogu yeMveliso yesiXhobo soBuchule beLaser

Ukuthengwa kwezinto ezininzi okanye iimveliso ezilungiselelwe, nceda uqhagamshelane nenkonzo yabathengi kwi-intanethi, okanyeshiya umyalezo.

Unako kwakhona ukuthumela i-imeyile kusales@herolaser.net.