- Izixhobo ze-Laser Welding ezizenzekelayo

- I-Automatic Fiber Laser Welding Robot

- 3/4/6 Axis Umatshini wokuWelding weLaser ozenzekelayo

- Amandla aphezulu 12KW Laser Welding Machine

- Ukulungisa uMngundo i-YAG Laser Welding Machine

- Isikhululo esiphindwe kabini sobushushu obungaguqukiyo kumatshini wokuthambisa we-laser

- Iiglasi umatshini welding oluzenzekelayo laser

- Umatshini wokuWelding weLaser ophathwa ngesandla

- Umatshini wokusika iLaser

- Ubungakanani obuNcinci obuCwangcisiweyo beFiber Laser Cutting Machine

- Umatshini wokusika iFayibha Laser (3015 series)

- IFayibha Laser Cutting Machine (6025 series)

- ILaser Cutting Machine yeMetal Sheet/Plate (ML-CB-3015FB)

- Tube Laser Cutting Machine (6016 Series)

- Umatshini wokusika umbhobho weLaser (QX series)

- Umatshini wokucoca ngeLaser

- Umatshini wokuMakisha weLaser

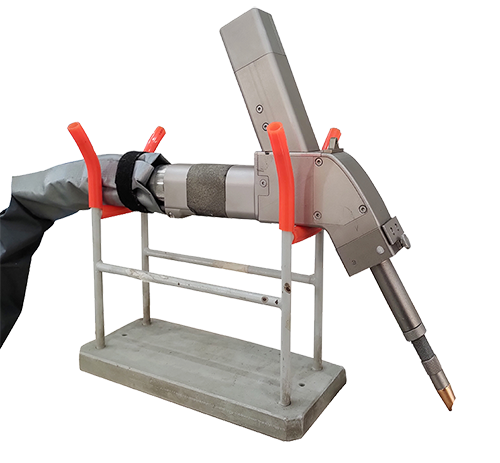

Umatshini wokuWelding weFiber Laser ophathwa ngesandla (Uguqulelo lwe-Euro)

Intshayelelo yeMveliso

Uninzi lweentengiso kwiimarike zilawulwa yi-welding yesandla epholile ngamanzi.Iwelding ebanjwa ngesandla ngamanzi epholiswe ngamanzi isebenzisa amanzi njengendawo yokupholisa.Inkampani yethu ithengisa oomatshini bokuwelda bamanzi apholileyo abanamandla ahlukeneyo afana ne-500W, 800W, 1000W, 1500W, 2000W, 3000W, njl. Kwaye i-welding ebanjwe ngesandla igxininisa kwiimodeli ezintathu: 1000W, 1500W, kunye ne-2000W.

Iimpawu zomatshini we-welding we-handheld wamanzi: eyakhelwe-kwi-double-ubushushu obumbini-ulawulo lwe-industrial chiller, ukulawulwa kweqondo lokushisa rhoqo kunye nokutshatyalaliswa kobushushu, ukuqinisekisa ukuchithwa kobushushu kumacandelo e-core optical circuit.Ngefiber laser, ezinzile kwaye esebenzayo

Iiparamitha zobuGcisa

| Amandla eLaser | 1000W/ 1500W/ 2000W/ 3000W |

| Ubude beLaser | 1070nm |

| Ubude beFayibha | Ukucwangciswa okusemgangathweni: 10M, inkxaso ephezulu: 15m |

| Imo yokusebenza | Ukuqhubeka / ukumodareyitha |

| Uluhlu lwesantya somatshini wokuwelda | 0-120 mm/s |

| Umatshini wamanzi okupholisa | Itanki yamanzi ye-industrial thermostatic |

| Ubushushu obugciniwe | 15 ~ 35 ℃ |

| Ukufuma kwe-Ambient | < 70% akukho condensation |

| Ubungqingqwa be-welding | 0.5-3mm |

| Iimfuno ze-Gap | ≤0.5mm |

| I-Voltage esebenzayo | I-AC220V |

| Ubungakanani | 1100mm x 570mm x 1180mm |

| Ubunzima | 220kg |

Iimpawu eziphambili

1. I-WOBBLE ephathwayo ngentloko yelaser, ilula kwaye ibhetyebhetye, inokuwelda nayiphi na indawo yomsebenzi

2. Eyakhelwe-ngaphakathi-ubushushu obumbini-ulawulo lwemizi-mveliso yokupholisa

3. Ukulawulwa kweqondo lokushisa rhoqo kunye nokutshatyalaliswa kobushushu ukuqinisekisa ukutshatyalaliswa kobushushu bamacandelo e-core optical circuit.

4. Ukusebenza okulula, kunokusebenza ngokulula ngoqeqesho olulula

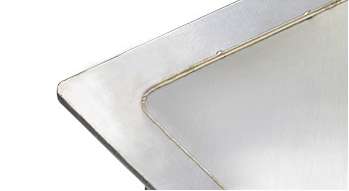

5. Iimveliso ezintle zinokudityaniswa enye ithathe ngaphandle kwenkosi

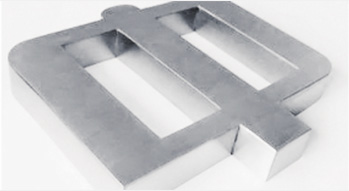

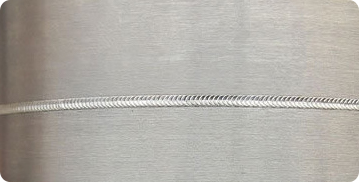

Ukuwelda kweFillet

I-Lap welding

Welding welding

Umthungo welding

Iteknoloji ye-welding ye-welding ye-welding joint

Umdibaniso we-welding welding uphuhliswa ngokuzimeleyo, kunye nemowudi ye-welding, ububanzi bendawo ehlengahlengiswayo kunye nokunyamezelana okunamandla kwe-welding, eyenza ukungabikho kwendawo yokuwelda i-laser encinci, yandisa uluhlu lonyamezelo kunye nobubanzi be-weld yamacandelo okucubungula, kwaye ifumana ukubunjwa kwe-weld engcono. .

1. I-weld formability engcono kunye ne-high-quality spot welding

2. I-fuselage kunye nentloko ye-laser ineemfuno ezisezantsi zamandla e-laser

3. Uluhlu oluvumelekileyo lobubanzi be-weld luya kwandiswa, kwaye i-weld iya kuba ntle ngaphandle kokuguqulwa

4. Ubuchule obugqwesileyo be-aluminium alloy bonding, umgangatho ophezulu wokuphindaphinda ukuphindaphinda kunye nokuzinza

Iimeko zeSicelo

Lo matshini wokuwelda ngesandla we-laser ufanelekile ukuwelda igolide, isilivere, i-titanium, i-nickel, i-tin, i-copper, i-aluminiyam kunye nezinye isinyithi kunye ne-alloy material yayo, inokufikelela kwi-welding efanayo echanekileyo phakathi kwesinyithi kunye nesinyithi esingafaniyo, isetyenziswe ngokubanzi kwizixhobo ze-aerospace. , ukwakhiwa kweenqanawa, izixhobo zokusebenza, oomatshini kunye neemveliso zombane, iimoto kunye namanye amashishini.

Iindaba zeemveliso ezinxulumeneyo kunye neevidiyo

Laser Welding Machine

nge-21 ka-Epreli,2022

Laser Welding Machine

nge-21 ka-Epreli,2022

Laser Welding Machine

nge-21 ka-Epreli,2022

nge-21 ka-Epreli,2022

Kubomi bethu bemihla ngemihla, asinakuphila ngaphandle kwekhitshi kunye negumbi lokuhlambela.Ikhitshi langoku kunye negumbi lokuhlambela libandakanya isilingi, ikhitshi kunye nefenitshala yokuhlambela ...

nge-21 ka-Epreli,2022

Kubomi bethu bemihla ngemihla, asinakuphila ngaphandle kwekhitshi kunye negumbi lokuhlambela.Ikhitshi langoku kunye negumbi lokuhlambela libandakanya isilingi, ikhitshi kunye nefenitshala yokuhlambela ...

nge-21 ka-Epreli,2022

Kubomi bethu bemihla ngemihla, asinakuphila ngaphandle kwekhitshi kunye negumbi lokuhlambela.Ikhitshi langoku kunye negumbi lokuhlambela libandakanya isilingi, ikhitshi kunye nefenitshala yokuhlambela ...

Uhlalutyo lwamandla we-laser welding

| Amandla eLaser | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Izinto eziphathekayo | ubukhulu | |||||||||

| Yenziwe ngentsimbi eshayinayo | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Intsimbi yekhabhoni | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Aluminiyam | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

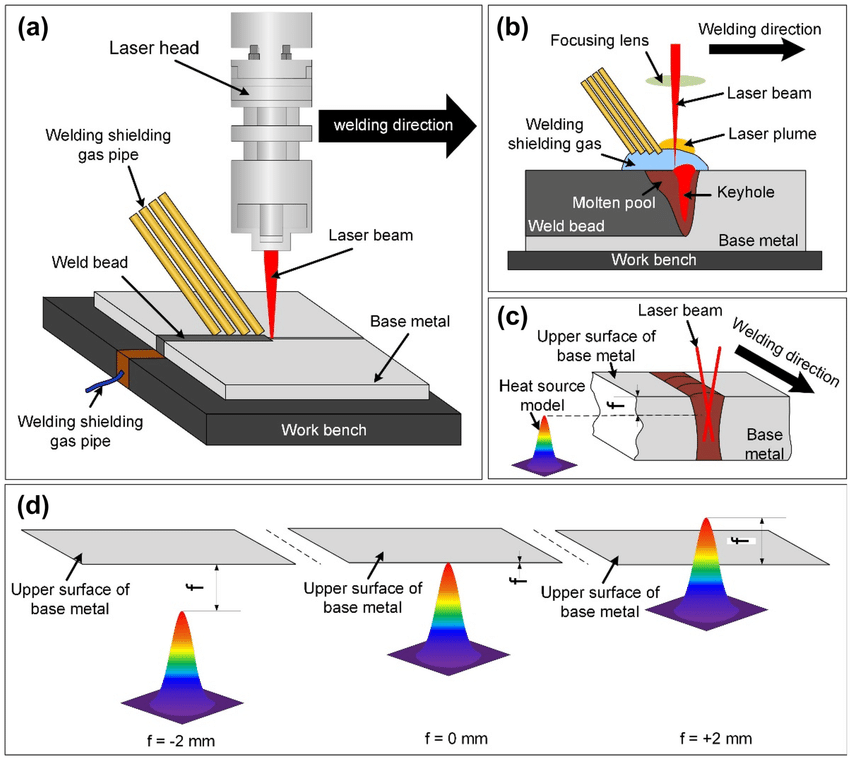

Umzobo wenkqubo ye-laser welding:

Iintlobo ezahlukeneyo ze-laser welding:

| Uhlobo lweLaser | Ubude bamaza | Imo yokuphuma | Isicelo |

| CW ifayibha laser | 1070nm | Ngokuqhubekayo | Ukuwelda okungapheliyo/okuqhubekayo kwentsimbi efanayo Modulated pulse spot welding |

| YAG laser | 1064nm | Ukubetha | Ukufakwa kwe-spot welding / weld seam yentsimbi efanayo |

| QCW ifayibha laser | 1070nm | Ukubetha kwentliziyo/okuqhubekayo | Metal Spot Welding / Continuous Seal Welding |

| I-laser ye-semiconductor | 808nm, 915nm, 980nm | Ukubetha kwentliziyo/okuqhubekayo | Ukuwelda kwePlastiki/I-Laser Soldering |

I-HEROLASER Ikhathalogu yeMveliso yesiXhobo soBuchule beLaser

Ukuthengwa kwezinto ezininzi okanye iimveliso ezilungiselelwe, nceda uqhagamshelane nenkonzo yabathengi kwi-intanethi, okanyeshiya umyalezo.

Unako kwakhona ukuthumela i-imeyile kusales@herolaser.net.

cela elona xabiso lilungileyo

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu