- I-Automatic Laser Welding Equipment

- I-Handheld Laser Welding Machine

- Laser Cutting Machine

- Umshini Wokusika I-Laser Usayizi Omncane Precision Fiber

- Umshini wokusika we-Fiber Laser (uchungechunge lwe-3015)

- I-Fiber Laser Cutting Machine (uchungechunge lwe-6025)

- Umshini Wokusika I-Laser Weshidi Lensimbi/I-Plate (ML-CB-3015FB)

- I-Tube Laser Cutting Machine (6016 Series)

- Tube Laser cutting machine (QX series)

- Umshini Wokuhlanza I-Laser

- Umshini Wokumaka we-Laser

Umshini Wokushisela I-Laser Ephathwayo (Okuvamile)

Isingeniso Somkhiqizo

Njengoba isungulwe okokuqala yi-Herolaser, umshini wokushisela ophathwa ngesandla ungena nesizukulwane sakamuva se-fiber laser, i-automatic wire feeder kanye nekhanda lokushisela elisanda kwakhiwa, okwenza kuhluke ngokuphelele ukugcwalisa igebe lemakethe yokushisela ye-laser ephathwayo.

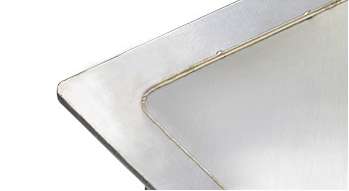

Ngeziqondiso ezilula, umshini usebenza endaweni yokushisela efanelekile ngesikhathi esifanele futhi ayidingi i-electrode yezinto ezisetshenziswayo, ethatha indawo ngokuphelele indlela yokucubungula yemishini yokushisela yensimbi yensimbi esebenza ngesandla phezu kwepuleti elincane lensimbi engagqwali, ipuleti lensimbi nepuleti likathayela.Ngenxa yokuguquguquka kwawo kwe-welding ekubunjweni okungajwayelekile kwezinto zokusebenza, umshini usetshenziswa kakhulu emakhabetheni nasezitsha zekhishi, izitebhisi zezandla namakheshi, ama-racks esitolo, ohhavini, imigoqo yokuqapha iminyango namafasitela, amabhokisi okusabalalisa amandla, ifenisha yensimbi engagqwali nezinye izimboni.

Umshini wamukela umklamo osebenziseka kalula kanye nobuchwepheshe obuthuthukisiwe, uma uqhathaniswa nemishini yokushisela yendabuko, okwenza abashisela basebenze ngendlela ephumelela kakhudlwana, ephephile, yokonga amandla kanye nendlela evumelana nemvelo.Ijubane lokushisela lishesha izikhathi ezi-3 kuye kweziyi-10 kunangaphambili ngenkathi lisiza futhi limboza kakhulu ibhajethi yakho.Umshini wokushisela ophathwa ngesandla we-Herolaser - yenza abashiseli bathande imisebenzi yabo nakakhulu.

Imingcele Yezobuchwepheshe

| Laser Amandla | 1000W/1500W/2000W/3000W |

| Laser wavelength | 1070nm |

| Ubude be-Fiber | Ukucushwa okujwayelekile: 10M, ukwesekwa okuphezulu: 15m |

| Imodi yokusebenza | Okuqhubekayo / ukuguquguquka |

| Ibanga lejubane lomshini wokushisela | 0-120 mm/s |

| Umshini wokupholisa amanzi | Ithangi lamanzi le-industrial thermostatic |

| I-Ambient Temperature | 15 ~ 35 ℃ |

| Umswakamo we-Ambient | < 70% akukho condensation |

| Welding ukujiya | 0.5-3mm |

| Izidingo zegebe | ≤0.5mm |

| I-Voltage esebenzayo | I-AC220V |

| Usayizi | 1100mm x 570mm x 1180mm |

| Isisindo | 220kg |

Izici ezibalulekile

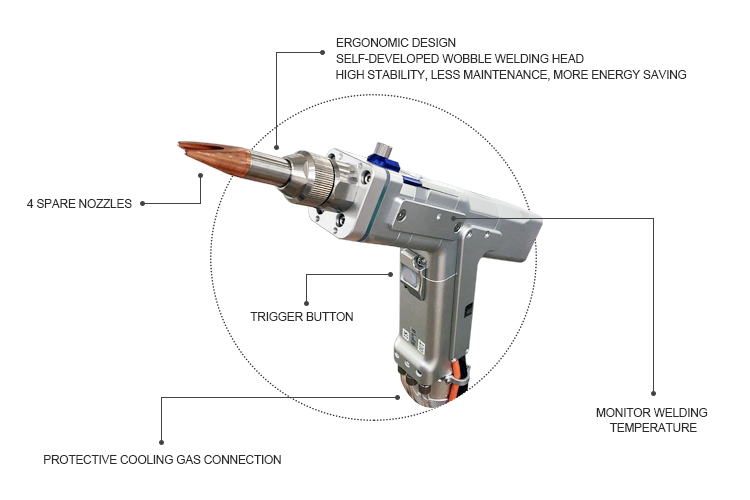

Ubuchwepheshe be-Swing welding bokuhlanganiswa okuhlanganisiwe

Ijoyinti yokushisela i-wobble ithuthukiswa ngokuzimela, inemodi yokushisela, ububanzi bendawo obuguquguqukayo kanye nokubekezelelana okuqinile kwe-welding, okwenza kube nobubi bendawo encane yokushisela i-laser, inweba ukubekezelelana nobubanzi be-weld yezingxenye zokucubungula, futhi ithole ukwakheka okungcono kwe-weld. .

1. Ukwakheka kwe-weld okungcono kanye nokushisela indawo okuseqophelweni eliphezulu

2. I-fuselage nekhanda le-laser kunezidingo eziphansi zamandla we-laser

3. Ububanzi obuvumelekile bobubanzi be-weld buzonwetshwa, futhi i-weld izoba yinhle ngaphandle kokuguqulwa

4. Ikhono elihle kakhulu le-aluminium alloy bonding, izinga eliphezulu lokucubungula ukuphindaphinda nokuzinza

I-WOBBLE ephathwayo ye-laser head, elula futhi evumelana nezimo, ingashisela noma iyiphi ingxenye yomsebenzi, yenze umsebenzi wokushisela usebenze kahle, uphephe, wonga amandla futhi uvumelane nemvelo.

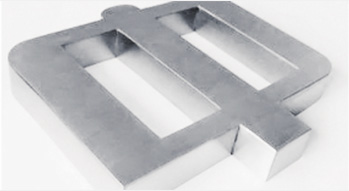

Ukushisela i-fillet

I-Lap Welding

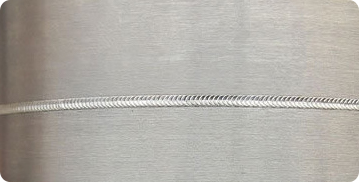

Umthungi we-welding

Ukuthunga ukushisela

Izici zomshini wokushisela ophethwe ngesandla opholiswe ngamanzi

I-double-control eyakhelwe ngaphakathi ye-dual-control industrial chiller.ukulawulwa njalo kwezinga lokushisa kanye nokukhishwa kokushisa, ukuze kuqinisekiswe ukushabalaliswa kokushisa kwezingxenye ze-core optical circuit.Nge-fiber laser, ezinzile futhi esebenza kahle.

Isikrini sokuthinta esihlanganisiwe

Ukusebenza kwephaneli yokubonisa izilimi eziningi, kulula ukuyiqonda, asikho isipiliyoni esidingekayo, ukuqeqeshwa kwamahhala, kulula ukuyiqonda

I-fuselage eqinile

I-fuselage yenziwe ngezinto eziqinile, ezihlala isikhathi eside, ikhwalithi ethembekile, isondlo esincane futhi sizinzile

10-15m intambo yefiber optical

Ikhebula le-fiber optical elingu-10-15m lihlelwa phakathi kwekhanda le-laser nomsingathi, elilungele ukushisela ngeselula kanye nesicelo esivumelana nezimo.

Izimo zohlelo lokusebenza

Lo mshini wokushisela we-laser ophathwa ngesandla ulungele ukushiselwa kwegolide, isiliva, i-titanium, i-nickel, ithini, ithusi, i-aluminium nezinye insimbi nezinto zayo zengxubevange, ungafinyelela ukushisela okufanayo okunembayo phakathi kwensimbi nezinsimbi ezingafani, sekusetshenziswe kabanzi emishinini ye-aerospace. , ukwakhiwa kwemikhumbi, izinsimbi, imikhiqizo yemishini nekagesi, izimboni zezimoto nezinye.

Ukuhlaziywa kwamandla we-laser welding

| Amandla e-laser | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Okubalulekile | ukujiya | |||||||||

| Insimbi engagqwali | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Insimbi ye-carbon | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| I-Aluminium | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

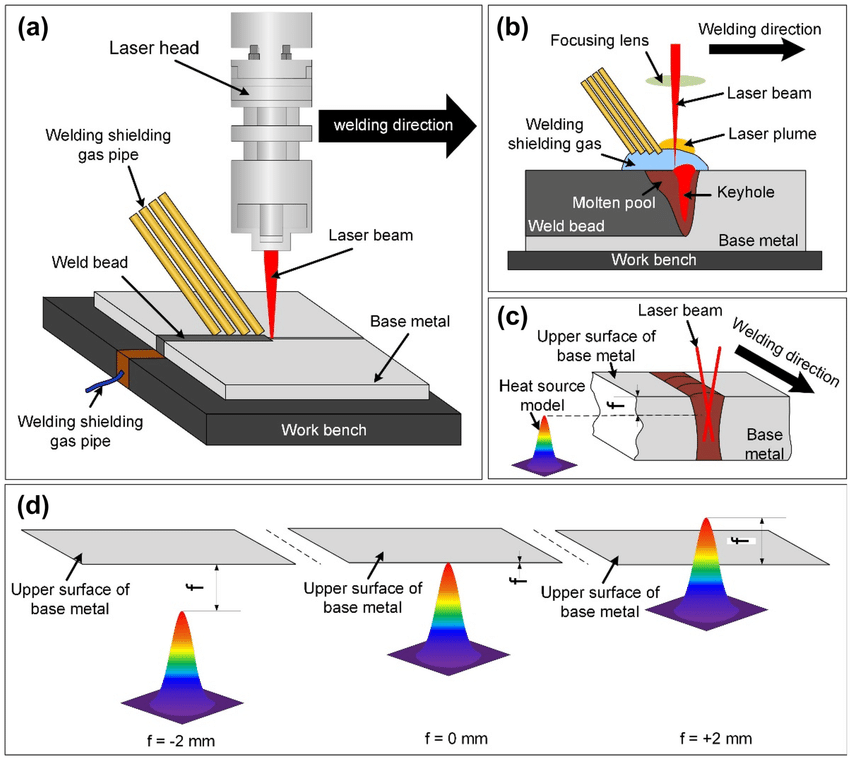

Umdwebo wesikimu wenqubo ye-laser welding:

Izinhlobo ezahlukene ze-laser welding:

| Uhlobo lwe-laser | Ubude begagasi | Imodi yokukhipha | Isicelo |

| CW fiber laser | 1070nm | Okuqhubekayo | Ukushisela okuphakathi/okuqhubekayo kwensimbi efanayo I-Modulated pulse spot welding |

| I-laser ye-YAG | 1064nm | I-Pulse | Spot welding/weld seam izicelo zensimbi efanayo |

| I-QCW fiber laser | 1070nm | Ukushaya kwenhliziyo/okuqhubekayo | I-Metal Spot Welding / I-Seal Welding eqhubekayo |

| I-laser ye-semiconductor | 808nm, 915nm, 980nm | Ukushaya kwenhliziyo/okuqhubekayo | I-Plastic Welding/Laser Soldering |

I-HEROLASER Ikhathalogi Yomkhiqizo Wezinto Zokusebenza Ze-Laser Ehlakaniphile

Ukuthenga ngobuningi noma imikhiqizo eyenziwe ngokwezifiso, sicela uthinte isevisi yamakhasimende eku-inthanethi, nomashiya umlayezo.

Ungakwazi futhi ukuthumela i-imeyili kusales@herolaser.net.