- I-Automatic Laser Welding Equipment

- I-Handheld Laser Welding Machine

- Laser Cutting Machine

- Umshini Wokusika I-Laser Usayizi Omncane Precision Fiber

- Umshini wokusika we-Fiber Laser (uchungechunge lwe-3015)

- I-Fiber Laser Cutting Machine (uchungechunge lwe-6025)

- Umshini Wokusika I-Laser Weshidi Lensimbi/I-Plate (ML-CB-3015FB)

- I-Tube Laser Cutting Machine (6016 Series)

- Tube Laser cutting machine (QX series)

- Umshini Wokuhlanza I-Laser

- Umshini Wokumaka we-Laser

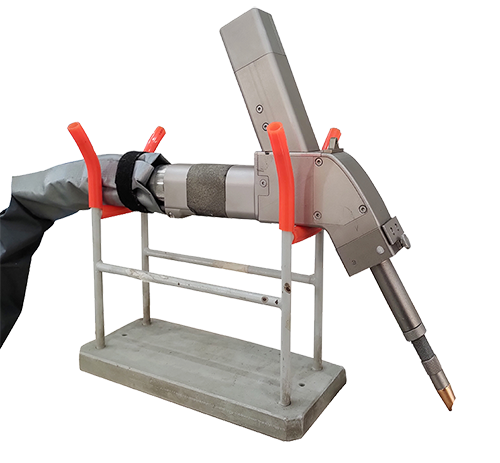

Umshini Wokushisela I-Fiber Laser Ephathwayo (Inguqulo ye-Euro)

Isingeniso Somkhiqizo

Ukuthengisa okuningi emakethe kubuswa ukushisela okubanjwa ngesandla okupholiswe ngamanzi.Ukushisela okubanjwa ngesandla okupholiswe ngamanzi kusebenzisa amanzi njengendawo yokupholisa.Inkampani yethu ithengisa imishini yokushisela epholile ngamanzi enamandla ahlukene afana ne-500W, 800W, 1000W, 1500W, 2000W, 3000W, njll. Futhi i-welding ebanjwe ngesandla igxile kumamodeli amathathu: 1000W, 1500W, kanye no-2000W.

Izici zomshini wokushisela ophethwe ngesandla opholiswe ngamanzi: okwakhelwe ngaphakathi okukabili-izinga lokushisa elikabili le-industrial chiller, ukulawulwa kwezinga lokushisa okungaguquki kanye nokukhipha ukushisa, ukuze kuqinisekiswe ukushiswa kokushisa kwezingxenye eziyinhloko zesekethe ye-optical.Nge-fiber laser, izinzile futhi isebenza kahle

Imingcele Yezobuchwepheshe

| Laser Amandla | 1000W/1500W/2000W/3000W |

| Laser wavelength | 1070nm |

| Ubude be-Fiber | Ukucushwa okujwayelekile: 10M, ukwesekwa okuphezulu: 15m |

| Imodi yokusebenza | Okuqhubekayo / ukuguquguquka |

| Ibanga lejubane lomshini wokushisela | 0-120 mm/s |

| Umshini wokupholisa amanzi | Ithangi lamanzi le-industrial thermostatic |

| I-Ambient Temperature | 15 ~ 35 ℃ |

| Umswakamo we-Ambient | < 70% akukho condensation |

| Welding ukujiya | 0.5-3mm |

| Izidingo zegebe | ≤0.5mm |

| I-Voltage esebenzayo | I-AC220V |

| Usayizi | 1100mm x 570mm x 1180mm |

| Isisindo | 220kg |

Izici ezibalulekile

1. I-WOBBLE ephathwayo ye-laser head, ilula futhi ivumelana nezimo, ingashisela noma iyiphi ingxenye ye-workpiece

2. Eyakhelwe ngaphakathi enamazinga okushisa amabili okulawula okukabili kwemboni

3. Ukulawulwa njalo kwezinga lokushisa kanye nokukhishwa kokushisa ukuze kuqinisekiswe ukuchithwa kokushisa kwezingxenye eziyinhloko zesekethe ye-optical circuit.

4. Ukusebenza okulula, kungenziwa kalula ngokuqeqeshwa okulula

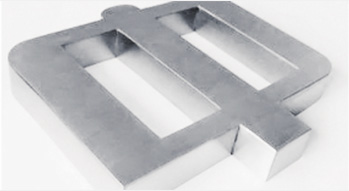

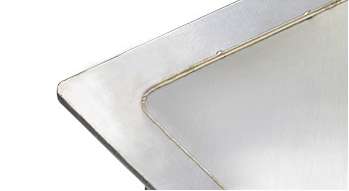

5. Imikhiqizo emihle ingafakwa i-welded eyodwa ithathe ngaphandle kwenkosi

Ukushisela i-fillet

I-Lap Welding

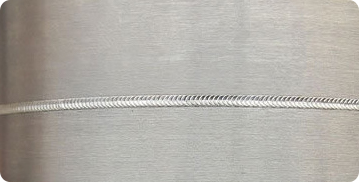

Umthungi we-welding

Ukuthunga ukushisela

Ubuchwepheshe be-Swing welding bokuhlanganiswa okuhlanganisiwe

Ijoyinti yokushisela i-wobble ithuthukiswa ngokuzimela, inemodi yokushisela, ububanzi bendawo obuguquguqukayo kanye nokubekezelelana okuqinile kwe-welding, okwenza kube nobubi bendawo encane yokushisela i-laser, inweba ukubekezelelana nobubanzi be-weld yezingxenye zokucubungula, futhi ithole ukwakheka okungcono kwe-weld. .

1. Ukwakheka kwe-weld okungcono kanye nokushisela indawo okuseqophelweni eliphezulu

2. I-fuselage nekhanda le-laser kunezidingo eziphansi zamandla we-laser

3. Ububanzi obuvumelekile bobubanzi be-weld buzonwetshwa, futhi i-weld izoba yinhle ngaphandle kokuguqulwa

4. Ikhono elihle kakhulu le-aluminium alloy bonding, izinga eliphezulu lokucubungula ukuphindaphinda nokuzinza

Izimo zohlelo lokusebenza

Lo mshini wokushisela we-laser ophathwa ngesandla ulungele ukushiselwa kwegolide, isiliva, i-titanium, i-nickel, ithini, ithusi, i-aluminium nezinye insimbi nezinto zayo zengxubevange, ungafinyelela ukushisela okufanayo okunembayo phakathi kwensimbi nezinsimbi ezingafani, sekusetshenziswe kabanzi emishinini ye-aerospace. , ukwakhiwa kwemikhumbi, izinsimbi, imikhiqizo yemishini nekagesi, izimboni zezimoto nezinye.

Izindaba zomkhiqizo ohlobene namavidiyo

Umshini Welding Laser

ngomhlaka-21 Ephreli, 2022

Umshini Welding Laser

ngomhlaka-21 Ephreli, 2022

Umshini Welding Laser

ngomhlaka-21 Ephreli, 2022

ngomhlaka-21 Ephreli, 2022

Ekuphileni kwethu kwansuku zonke, asikwazi ukuphila ngaphandle kwekhishi nendawo yokugezela.Ikhishi negumbi lokugezela lesimanje lihlanganisa uphahla, ikhishi nefenisha yokugezela ...

ngomhlaka-21 Ephreli, 2022

Ekuphileni kwethu kwansuku zonke, asikwazi ukuphila ngaphandle kwekhishi nendawo yokugezela.Ikhishi negumbi lokugezela lesimanje lihlanganisa uphahla, ikhishi nefenisha yokugezela ...

ngomhlaka-21 Ephreli, 2022

Ekuphileni kwethu kwansuku zonke, asikwazi ukuphila ngaphandle kwekhishi nendawo yokugezela.Ikhishi negumbi lokugezela lesimanje lihlanganisa uphahla, ikhishi nefenisha yokugezela ...

Ukuhlaziywa kwamandla we-laser welding

| Amandla e-laser | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Okubalulekile | ukujiya | |||||||||

| Insimbi engagqwali | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Insimbi ye-carbon | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| I-Aluminium | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

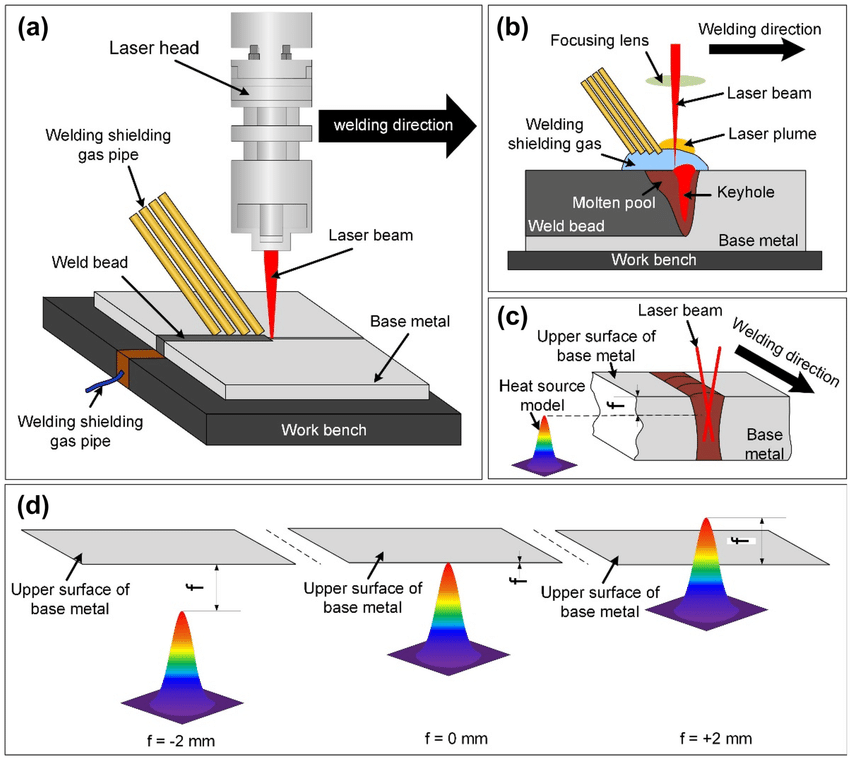

Umdwebo wesikimu wenqubo ye-laser welding:

Izinhlobo ezahlukene ze-laser welding:

| Uhlobo lwe-laser | Ubude begagasi | Imodi yokukhipha | Isicelo |

| CW fiber laser | 1070nm | Okuqhubekayo | Ukushisela okuphakathi/okuqhubekayo kwensimbi efanayo I-Modulated pulse spot welding |

| I-laser ye-YAG | 1064nm | I-Pulse | Spot welding/weld seam izicelo zensimbi efanayo |

| I-QCW fiber laser | 1070nm | Ukushaya kwenhliziyo/okuqhubekayo | I-Metal Spot Welding / I-Seal Welding eqhubekayo |

| I-laser ye-semiconductor | 808nm, 915nm, 980nm | Ukushaya kwenhliziyo/okuqhubekayo | I-Plastic Welding/Laser Soldering |

I-HEROLASER Ikhathalogi Yomkhiqizo Wezinto Zokusebenza Ze-Laser Ehlakaniphile

Ukuthenga ngobuningi noma imikhiqizo eyenziwe ngokwezifiso, sicela uthinte isevisi yamakhasimende eku-inthanethi, nomashiya umlayezo.

Ungakwazi futhi ukuthumela i-imeyili kusales@herolaser.net.

cela intengo engcono kakhulu

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu