Handheld Fiber Laser Welding Machine (Euro Version)

Product Sumo

Kuwanda kwekutengesa mumusika kunotungamirirwa nemvura-yakatonhodzwa nemaoko-inobata welding.Mvura-yakatonhodzwa nemaoko-inobata welding inoshandisa mvura semhepo yekutonhodza.Kambani yedu inotengesa mvura-yakatonhodzwa welding michina ine masimba akasiyana akadai 500W, 800W, 1000W, 1500W, 2000W, 3000W, etc. Uye inobatwa nemaoko inotarisa pamhando nhatu: 1000W, 1500W, uye 2000W.

Mvura-yakatonhorera handheld welding muchina maficha: akavakirwa-mukati maviri-tembiricha dual-control maindasitiri chiller, inogara ichitembiricha mutemo uye kupisa kupisa, kuve nechokwadi chekupisa kwekupisa kweiyo core optical circuit components.Ne fiber laser, yakagadzikana uye inoshanda

Technical Parameters

| Laser Simba | 1000W/1500W/2000W/3000W |

| Laser wavelength | 1070nm |

| Fiber Length | Kugadziriswa kwakajairwa: 10M, kutsigirwa kwakanyanya: 15m |

| Operation Mode | Kuenderera mberi / modulation |

| Welding muchina kumhanya siyana | 0-120 mm/s |

| Mushini wemvura inotonhorera | Industrial thermostatic water tank |

| Ambient Temperature | 15 ~ 35 ℃ |

| Ambient Humidity | <70% hapana condensation |

| Welding ukobvu | 0.5-3mm |

| Gap zvinodiwa | ≤0.5mm |

| Kushanda Voltage | AC220V |

| Size | 1100mm x 570mm x 1180mm |

| Kurema | 220kg |

Core Features

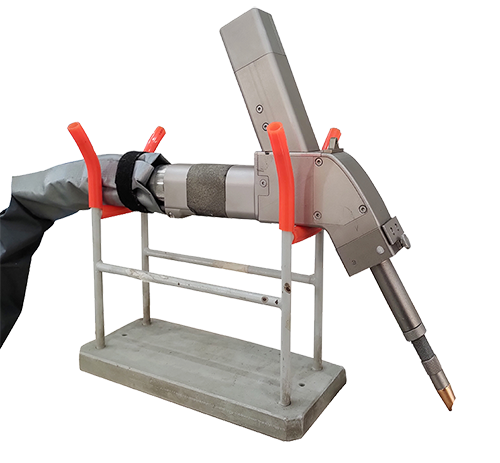

1. WOBBLE handheld laser musoro, yakareruka uye inochinjika, inogona weld chero chikamu cheworkpiece

2. Yakavakwa-mukati-inopisa mbiri-inodzora maindasitiri chiller

.

4. Kushanda kuri nyore, kunogona kushandiswa nyore nyore nekudzidzira nyore

5. Zvigadzirwa zvakanaka zvinogona kusungirirwa imwe inotora pasina tenzi

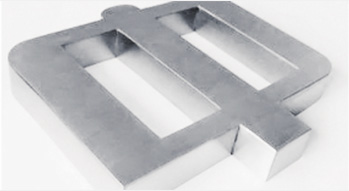

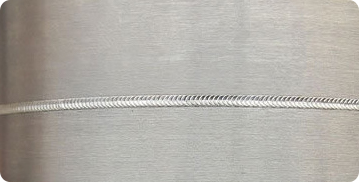

Fillet welding

Lap welding

Tailor welding

Sona welding

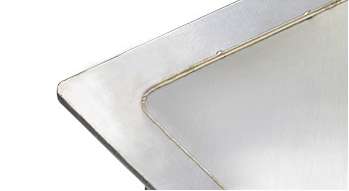

Swing welding tekinoroji yejoini yakasungwa

Iyo wobble welding joint inogadzirwa yakazvimiririra, ine swing welding mode, inogadziriswa nzvimbo hupamhi uye yakasimba welding kukanganisa kushivirira, iyo inogadzirisa kusakosha kwediki laser welding nzvimbo, inowedzera kushivirira renji uye weld hupamhi hwekugadzirisa zvikamu, uye inowana zvirinani weld kugadzira. .

1. Zvirinani weld formability uye yemhando yepamusoro nzvimbo welding

2. The fuselage uye laser musoro vane yakaderera zvinodiwa Laser simba

3. Iyo inotenderwa yehupamhi hweweld ichawedzerwa, uye weld ichave yakanaka pasina deformation

4. Yakanakisa aluminium alloy bonding kugona, yepamusoro-mhando yekugadzirisa kudzokorora uye kugadzikana

Application Scenarios

Muchina uyu wakabatwa nemaoko welaser welding wakakodzera simbi yegoridhe, sirivheri, titanium, nickel, tini, mhangura, aluminiyamu uye imwe simbi nezvinhu zvayo zvealloy, inokwanisa kuwana simbi yakafanana nesimbi nesimbi dzakasiyana, yave kushandiswa zvakanyanya mumidziyo yemuchadenga. , shipbuilding, instrumentation, mechanical uye magetsi zvigadzirwa, motokari uye mamwe maindasitiri.

Related chigadzirwa nhau uye mavhidhiyo

Laser Welding Machine

musi waKubvumbi 21,2022

Laser Welding Machine

musi waKubvumbi 21,2022

Laser Welding Machine

musi waKubvumbi 21,2022

musi waKubvumbi 21,2022

Muhupenyu hwedu hwezuva nezuva, hatigone kurarama tisina kicheni neimba yekugezera.Kicheni yemazuva ano uye yekugezera inosanganisira sirin'i, kicheni uye yekugezera fenicha ...

musi waKubvumbi 21,2022

Muhupenyu hwedu hwezuva nezuva, hatigone kurarama tisina kicheni neimba yekugezera.Kicheni yemazuva ano uye yekugezera inosanganisira sirin'i, kicheni uye yekugezera fenicha ...

musi waKubvumbi 21,2022

Muhupenyu hwedu hwezuva nezuva, hatigone kurarama tisina kicheni neimba yekugezera.Kicheni yemazuva ano uye yekugezera inosanganisira sirin'i, kicheni uye yekugezera fenicha ...

Laser welding simba rekuongorora

| Laser simba | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | 8000W | 10000W | 12000W | |

| Material | ukobvu | |||||||||

| Simbi isina ngura | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 3 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 4 | √ | √ | √ | √ | √ | √ | √ | |||

| 5 | √ | √ | √ | √ | √ | √ | ||||

| 6 | √ | √ | √ | √ | √ | √ | ||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | ||||||||

| 15 | √ | |||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Carbon steel | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | √ | √ | ||||||

| 10 | √ | √ | √ | |||||||

| 12 | √ | √ | √ | |||||||

| 15 | √ | √ | ||||||||

| 20 | √ | |||||||||

| 25 | ||||||||||

| 30 | ||||||||||

| 40 | ||||||||||

| Aluminium | 1 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 2 | √ | √ | √ | √ | √ | √ | √ | √ | ||

| 3 | √ | √ | √ | √ | √ | √ | √ | |||

| 4 | √ | √ | √ | √ | √ | √ | ||||

| 5 | √ | √ | √ | √ | √ | |||||

| 6 | √ | √ | √ | √ | ||||||

| 8 | √ | √ | ||||||||

| 10 | √ | |||||||||

| 12 | ||||||||||

| 15 | ||||||||||

| 20 | ||||||||||

| 25 | ||||||||||

| 30 | ||||||||||

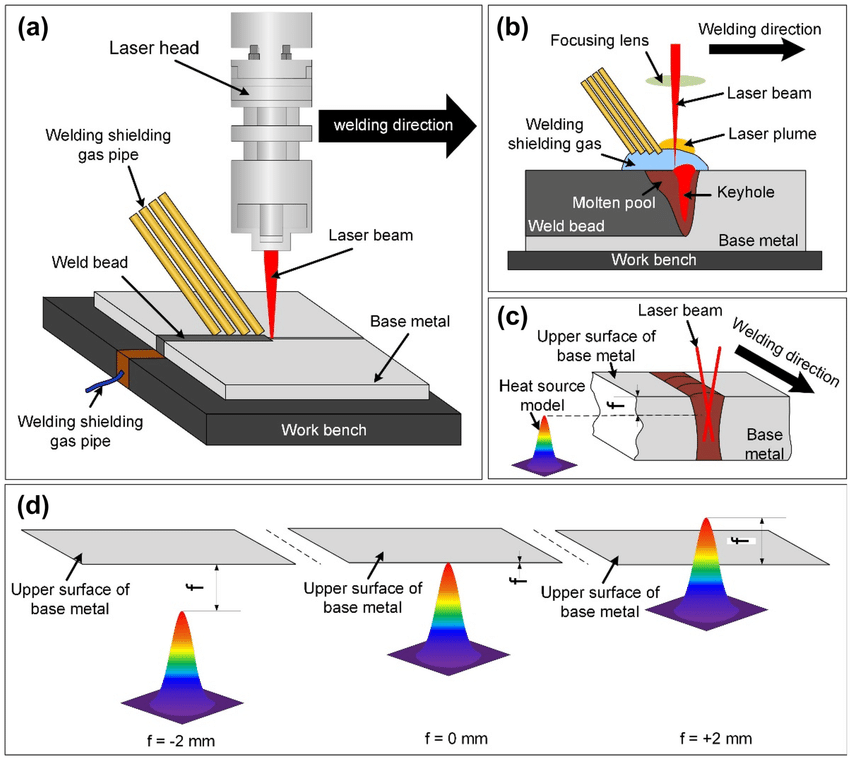

Iyo schematic dhizaini yeiyo laser welding process:

Mhando dzakasiyana dze laser welding:

| Laser mhando | Wavelength | Output mode | Application |

| CW fiber laser | 1070nm | Continuous | Kuchimbidzika/kuenderera mberi kwesimbi imwechete Modulated pulse spot welding |

| YAG laser | 1064nm | Pulse | Spot welding/weld seam application yesimbi imwe chete |

| QCW fiber laser | 1070nm | Pulse/inoenderera | Metal Spot Welding / Inoenderera Seal Welding |

| Semiconductor laser | 808nm, 915nm, 980nm | Pulse/inoenderera | Plastic Welding / Laser Soldering |

HEROLASER Akangwara Laser Processing Equipment Chigadzirwa Catalog

Nekutenga kwakawanda kana zvigadzirwa zvakagadzirirwa, ndapota taura neinternet service customer service, kanasiya meseji.

Iwe unogona zvakare kutumira email kunesales@herolaser.net.

kumbira mutengo wakanakisisa

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu